1 689 979 467 2012-10-10| Robert Bosch GmbH

26 | EPS 100 | Maintenanceen

6.5 Maintenance

! Every nozzle tester operator is responsible for ensuring

proper maintenance during the stipulated period.

The following function tests must be performed as part

of the EPS 100 maintenance routine.

The calibration set (Order number 1688130194)

contains components and measuring devices required

for maintenance and calibration activities. Description

1689979630 is included in the calibration set.

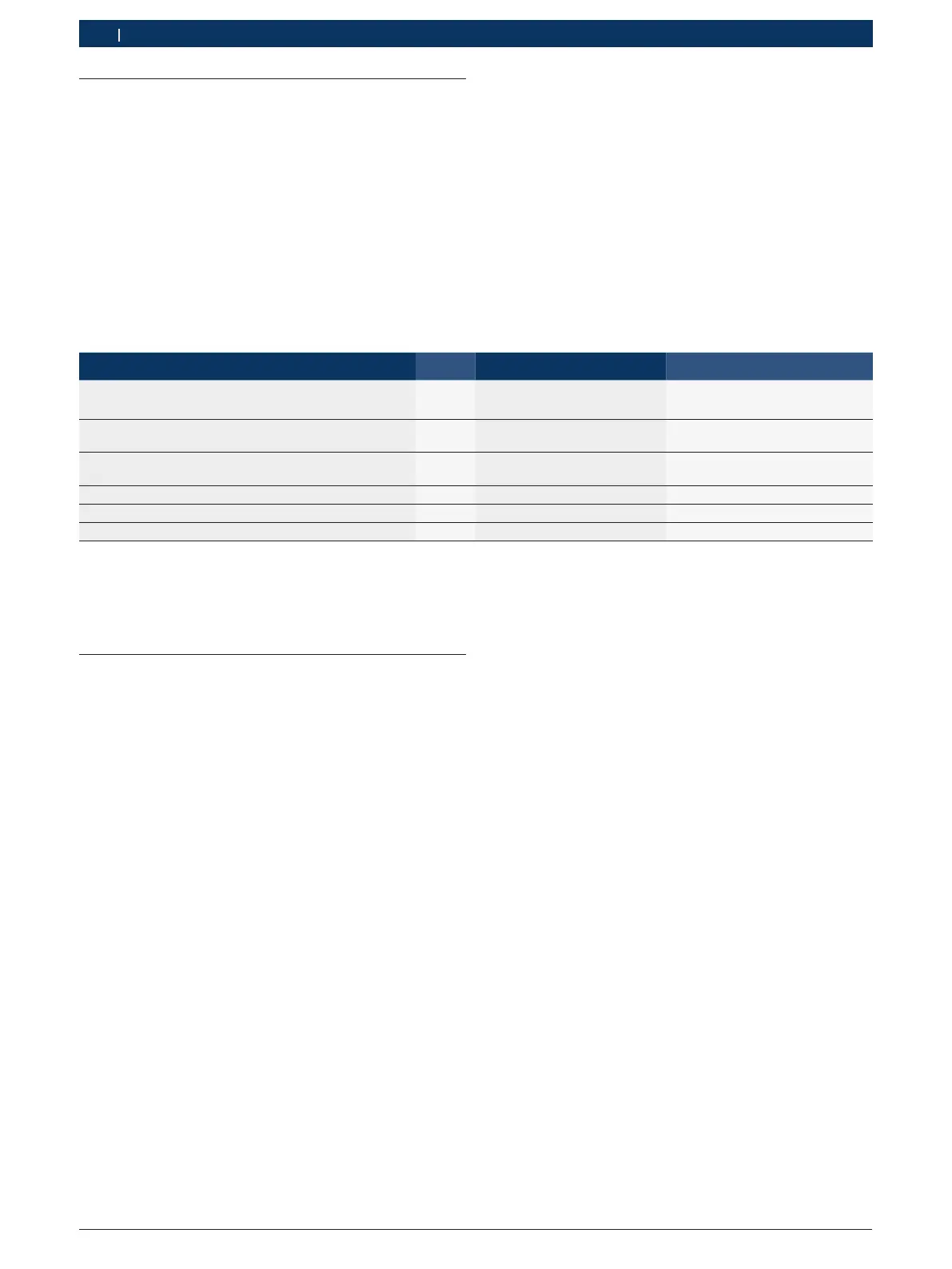

Maintenance schedule

Test Chapter Time interval (Additional) units required

1. Bleeding 2.4 Before each test (Item 2. – 5.) Any nozzle and holder and/or

system pressure of 100 bar

2. Tightness of the complete system 2.5 Every 24 months and at

pressure gauge change

Sealing piece

*)

3. Leak tightness of manometer shutoff valve and

return valve

2.6 Every 24 months Reference pressure gauge

*)

4. Function and accuracy of the pressure gauge 2.7 Every 24 months Reference pressure gauge

*)

5. Leak tightness of pump piston and inlet valve 2.8 Every 24 months Calibration set

6. Checking the volume elasticity 2.9 At pressure gauge change Calibration set

*)

included in the calibration set

The test on hydromechanical rigidity. This test is also

conducted with the calibration set, see Chapter 2.10.

6.6 Decommissioning

! Oils are hazardous to waters and must be disposed

of in accordance with the Waste Disposal Law.

i ISO test oil falls into used oil Category 1. It contains

processable, low viscosity, mineral engine and

gearbox oils. Used oil Category 1 may not contain

proportions of foreign substances such as other

categories of used oils or petrol.

The aforementioned used oils are disposed of via the

industrial waste disposal facility against a charge. This

requires the waste code number "54 112", in order to

guarantee proper disposal.

Loading...

Loading...