Applications Manual FHP560 Controller | 21

Bosch Thermotechnology Corp.

Data subject to changePage____ of ____

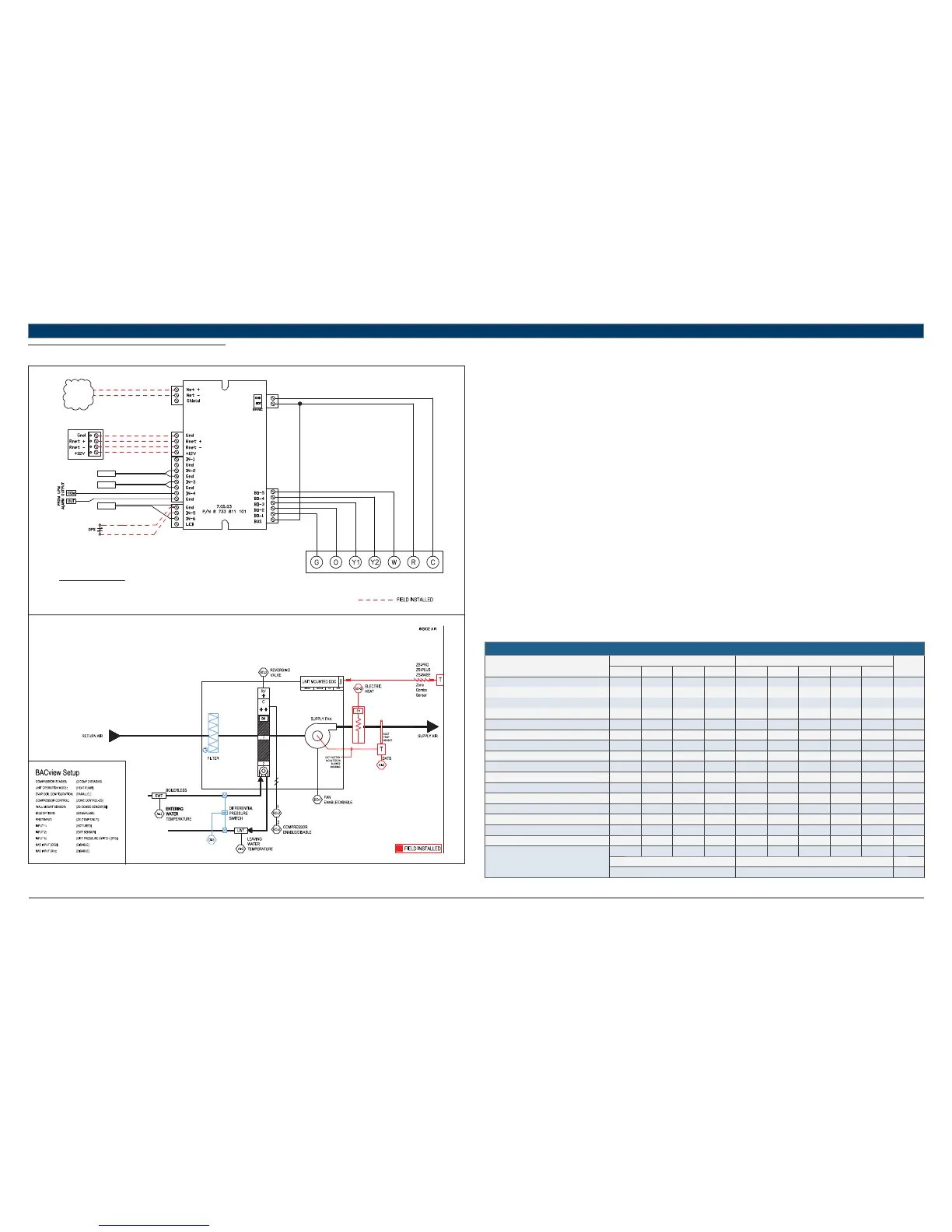

11.10 HP + BOILERLESS + DPS

TO BACnet

MS/TP

NETWORK

LWTS

RED

GREEN

WHITE

BLACK

TERMINATION DETAIL

RNET: SENSORS

STANDARD COMPONENTS:

DATS - DISCHARGE AIR TEMPERATURE SENSOR

LWTS - LEAVING WATER TEMPERATURE SENSOR

EWTS - ENTERING WATER TEMPERATURE SENSOR

REFER TO UNIT WIRING DIAGRAM FOR FURTHER DETAILS

EWTS

FHP560

DATS

Heat Pump Sequence of Operation – HP + BOILERLESS + DPS

Supply Fan Start/Stop:

The supply fan will be started according to the schedule. After the supply fan has been started the control sequence will be enabled.

Zone Control:

The compressor will cycle to maintain the zone temperature at setpoint.

Heat Pump Control:

When the zone temperature falls below the zone temperature setpoint the reversing valve will be disabled to provide heating when the

compressor is running. When the zone temperature rises above the zone temperature setpoint the reversing valve will be enabled to provide

cooling when the compressor is running.

Night Setback:

When in “unoccupied”, the unit will cycle as necessary to maintain the night setback zone temperature at setpoint.

Shutdown:

When the unit is shutdown by either a stop command or system safety the unit will be set as follows:

Supply fan will be on (user configurable)

Compressor(s) will be off

Boilerless Control:

Boilerless Control (BLC) option must be confi gured by the equipment integrator. A factory installed entering water temp sensor in IN-5 (IN-2 if IN-5

is unavailable) is used to enable boilerless control.

Entering water temperature values less than 40°F (user confi gurable) will enable boilerless control.

Compressor operation is disabled upon boilerless control signal being activated.

An electric heat package must be installed for boilerless control option. Electric heat will be enabled on output BO-5 when boilerless signal is

activated.

Differential Pressure Switch:

Differential pressure switch (DPS) option must be confi gured by the equipment integrator. A factory installed differential pressure switch is tied in

to the controller at the confi gured input (IN-5 or IEM) and used to prove fl ow prior to unit compressor operation.

If the DPS opens during normal heating/cooling operation, compressor operation is ceased after 15 secs and an alarm is generated.

Once the switch re-closes, a time delay prevents unit compressor operation until 3 mins has elapsed to ensure fl ow is fully re-established.

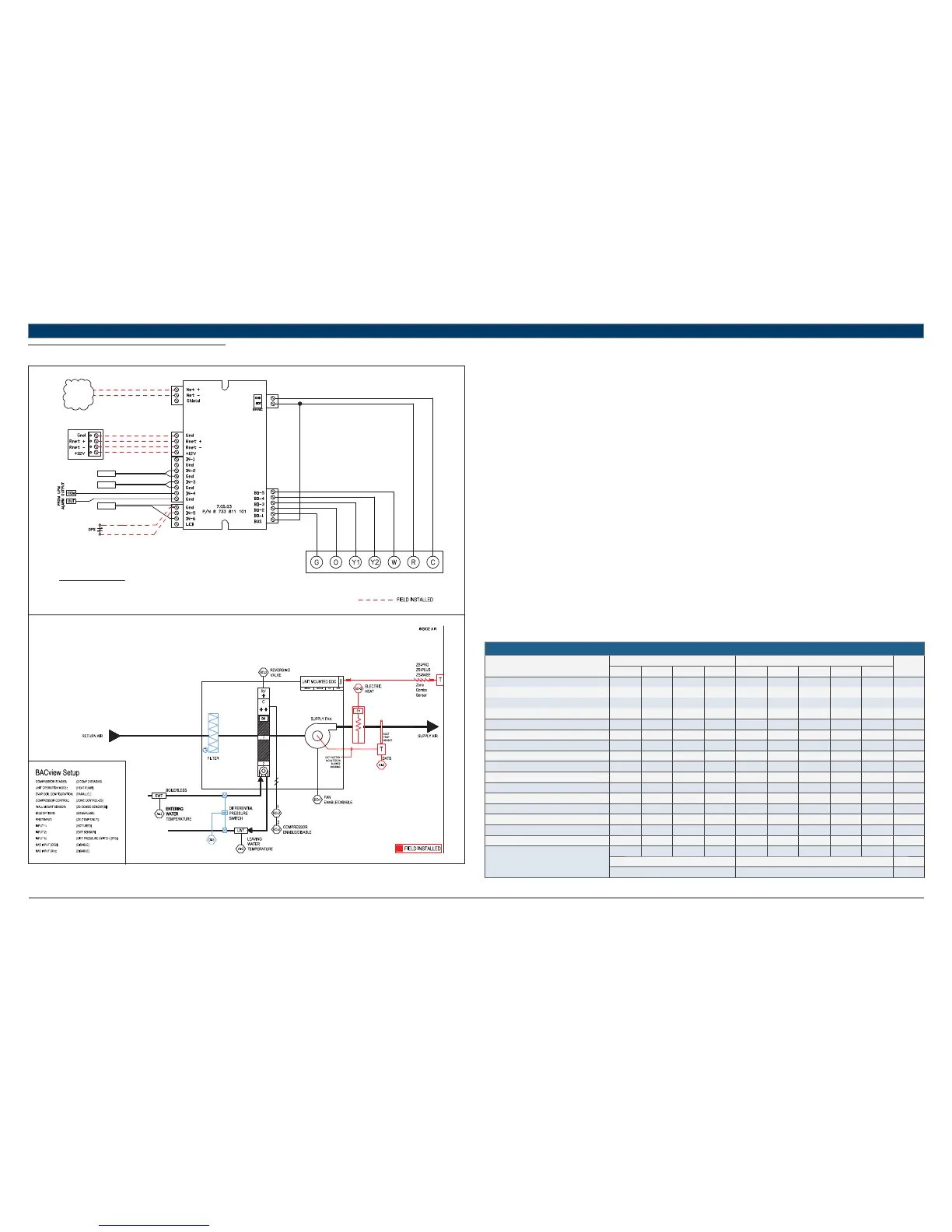

HEAT PUMP

Point Name

Hardware Points Software Points

Show On

Graphic

AI AO BI BO AV BV Sched Trend Alarm

Zone Temperature XXXX

Heating Setpoint XX

Cooling Setpoint XX

Supply Fan Command X X

Compressor Stage 1 Output X X

Compressor Stage 2 Output X X

Reversing Valve Command X X

Occupied Command XXXX

Discharge Air Temperature X X

Leaving Water Temperature X X

Entering Water Temperature X

Aux Electric Heat Output X

Differential Pressure Switch (DPS) X

Condensate Overfl ow X

Lockout Alarm X

Schedule

Totals

40253111210

Total Hardware Total Software

11 8 10

Table 18

Loading...

Loading...