28

|

FHP560 Controller Applications Manual

Bosch Thermotechnology Corp.

Data subject to change Page____ of ____

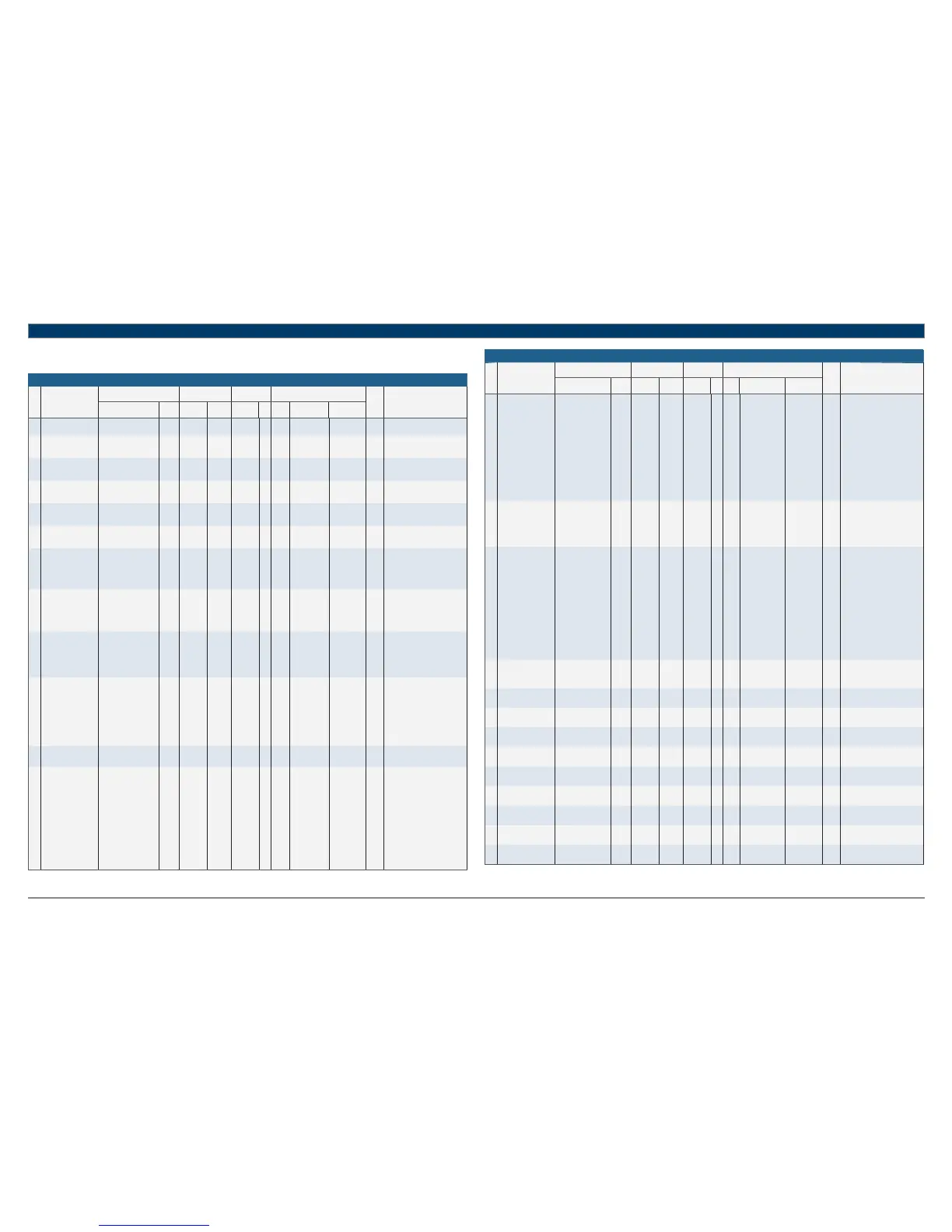

13 Integration Points List - Water-to-Air Standard Software 7.05.03

Integration Points

#

Point Description

Name

BACnet MODBUS N2 LON

Read

Only

Description

Name

Type

ID

Object

Type

Register Type ID

SNVT

#

Name SNVT

1 BAS CO₂ Sensor Value bas_CO₂_val_1 AV:49 fl oat value 40001 data fl oat 1 1 nviBasCO₂Val SNVT_ppm(29)

BAS CO₂ Sensor Value in PPM

Default: 1001 PPM

2 BAS Mixed Air Temp bas_mat_1 AV:86 fl oat value 40003 data fl oat 2 ‒‒ ‒

BAS Mixed Air Temperature Value

in °F

Default: 66.5 °F

3

BAS Outside Air

Temperature

effective_oat_1 AV:29 fl oat value 40005 data fl oat 3 0 nviEffectiveOAT

SNVT_

temp_p(105)

Effective Outside Air Temperature

in °F

Default: 60 °F

4 BAS RH Sensor Value bas_rh_sen_val_1 AV:56 fl oat value 40007 data fl oat 4 15 nviBasRhSenVal

SNVT_lev_

percent(81)

RH Sensor Value Supplied by BAS

in %

Default: 56 %RH

5

BAS Temperature

Sensor Value

bas_sen_val_1 AV:19 fl oat value 40009 data fl oat 5 2 nviBasSenVal

SNVT_

temp_p(105)

BAS Zone Temperature Sensor

Value in °F

Default: 74 °F

6

Evaporator Coil

Confi guration Selection

coil_cfg_1 AV:94 fl oat value 40011 data fl oat 6 ‒‒ ‒

Coil Confi guration Setup

0 = Parallel (Default)

1 = Series

7

Compressor Control

Mode

comp_mode_1 AV:64 fl oat value 40013 data fl oat 8 ‒‒ ‒

Compressor Mode Setup

0 = Zone Control - ZS (Default)

1 = Discharge Air Control

2 = Zone Control - BAS Sensor

3 = Zone Control - Remote Sensor

8 Compressor Stages cmp_stgs_1 AV:14 fl oat value 40001 data fl oat 7 16 nvoCmpStgs

SNVT_count_

inc(9)

Reports Confi guration Status of

Compressor Stages

1 = 1 Compressor 1 Stage

2 = 2 Compressor 2 Stages

5 = 1 Compressor 2 Stages

9

Compressor Stages

Selection

stages_1 AV:114 fl oat value 40107 data fl

oat 79 ‒‒ ‒

Selected Compressor Stages

(Confi gured at Factory)

1 = 1 Compressor 1 Stage

2 = 2 Compressor 2 Stages

5 = 1 Compressor 2 Stages

(Default)

10 Control Source ctrl_source_1 AV:15 fl oat value 40023 data fl oat 12 3 nviCtrlSource

SNVT_count_

inc(9)

Control Source for Occupancy

Setup

0 = Digital Input Enable (e.g. Room

Occupancy Sensor)

1 = Keypad Schedule

2 = BAS Occupancy Command

(Default)

3 = Factory Use Only

4 = Manual On-Continuous

11

Cooling Demand

Percentage

clg_pct_1 AV:13 fl oat value 40025 data fl oat 13 ‒‒ ‒

Cooling Status in Demand Percent,

%

12 IN-2 Mode Status ui2_mode_status_1 AV:18 fl oat value 40033 data fl oat 55 ‒‒ ‒

Reports how the controller Input

#2 (IN-2) is confi gured

0 = Not Used

1 = Zone Remote Sensor

2 = Outdoor Air Temperature

Sensor

3 = Entering Water Temperature

Sensor

4 = Mixed Air Temperature Sensor

5 = Relative Humidity Sensor

(Probe)

6 = Digital Enable (e.g. Room

Occupancy Sensor)

7 = Return Air Temperature Sensor

Table 23

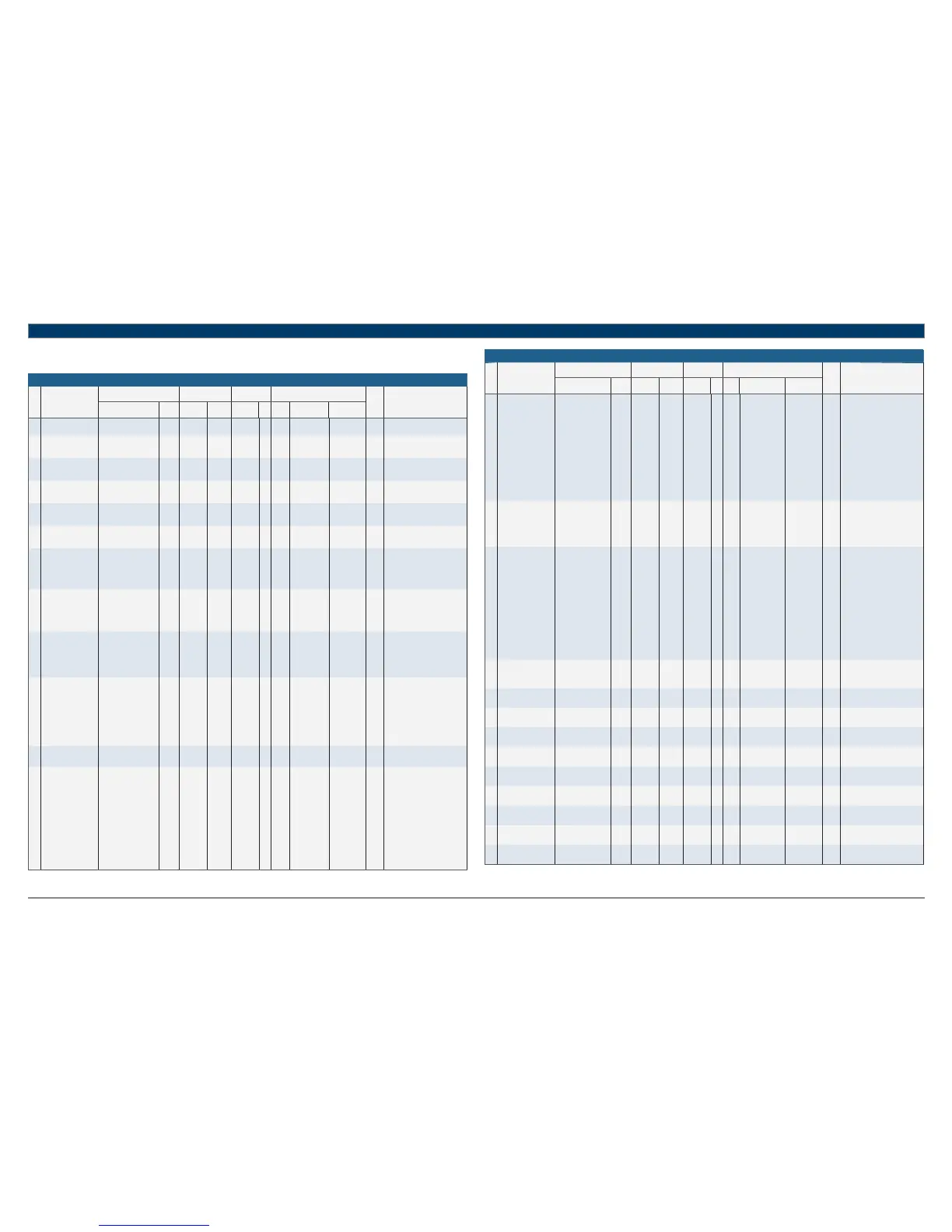

Integration Points

#

Point Description

Name

BACnet MODBUS N2 LON

Read

Only

Description

Name

Type

ID

Object

Type

Register Type ID

SNVT

#

Name SNVT

13

Current Alarm

Condition Status

current_alarm_1 AV:17 fl oat value 40003 data fl oat 9 17 nvoCurrentAlarm

SNVT_count_

inc(9)

Alarm Status of unit:

0 = No Alarm,

1-10 = UPM Fault Code

20 = Output Overridden via Keypad

30 = Sensor Failure

40 = Leaving Water Temp Alarm

50 = Zone Temp Alarm

60 = Discharge Air Temperature

Alarm

70 = Filter Alarm/Compressors 1 &

2 Runtime

80 = Zone Humidity Alarm

90 = High CO₂ Level Alarm

100 = Differential Pressure Switch

(DPS) Alarm"

14

Damper Occupancy

Selection

mdpr_occ_sel_1 AV:97 fl oat value 40031 data fl oat 16 ‒‒ ‒

Damper Occupancy Selection

Setup

0 = Disabled

1 = Occupied (Default)

2 = Unoccupied

3 = Any Occupancy

15

DI5 Mode (Digital

Input 5)

di5_mode_1 AV:60 fl oat value 40015 data fl oat 10 ‒‒ ‒

Controller Input #5 Confi guration

Selection

0 = Dirty Filter Switch

1 = Entering Water Temp Sensor -

Economizer/Boilerless

2 = Differential Pressure Switch

3 = Secondary Condensate Pan

4 = Fan Status Switch

5 = Valve End Switch

6 = Damper End Switch

7 = Smoke Detector Switch

8 = Pump Status Switch

9 = MIxed Air Temp Sensor - Mixed

Air Control

10 = Input Expansion Module (IEM)

11 = Not Used (Default)

16

Discharged Air

Temperature Setpoint

dat_stpt_1 AV:30 fl oat value 40017 data fl oat 11 18 nviDatStpt

SNVT_

temp_p(105)

Discharged Air Temperature

Setpoint Setup in °F

Default: 65 °F

17

Effective Cooling

Setpoint

eff_clg_stpt_1 AV:5 fl oat value 40039 data fl oat 20 4 nvoEffClgStpt

SNVT_

temp_p(105)

Effective Cooling Setpoint (after

setpoint adjustment applied) in °F

18 Effect Disch Air Temp eff_dat_1 AV:10 fl oat value 40011 data fl oat 18 21 nvoEffDat

SNVT_

temp_p(105)

Discharge Air Temperature (DAT)

in °F

19

Entering Water

Temperature

eff_ewt_1 AV:62 fl oat value 40013 data fl oat 19 22 nvoEffEwt

SNVT_

temp_p(105)

Water Side Economizer Effective

Entering Water Temperature in °F

20

Effective Heating

Setpoint

eff_htg_stpt_1 AV:6

fl oat value 40045 data fl oat 23 5 nvoEffHtgStpt

SNVT_

temp_p(105)

Effective Heating Setpoint (after

setpoint adjustment applied) in °F

21

Modulating Damper

Position

eff_dpr_pos_screen_1 AV:81 fl oat value 40047 data fl oat 24 ‒‒ ‒

Effective Outside Air Damper

Position in %

22 Zone Humidity eff_zone_humid_1 AV:20 fl oat value 40021 data fl oat 26 24 nvoEffZoneHumid

SNVT_lev_

percent(81)

Effective Zone Humidity in Percent

RH (%)

23

Leaving Water

Temperature (LWT)

eff_lwt_1 AV:11 fl oat value 40015 data fl oat 21 23 nvoEffLwt

SNVT_

temp_p(105)

Effective Leaving Water

Temperature Status in °F

24

Mixed Air Temperature

(MAT)

eff_mat_1 AV:87 fl oat value 40017 data fl oat 22 ‒‒ ‒

Effective Mixed Air Temperature

in °F

25

Outdoor Air

Temperature (OAT)

eff_oat_1 AV:75 fl oat value 40055 data fl oat 28 6 nvoEffOat

SNVT_

temp_p(105)

Effective Outdoor Temperature

Status in °F

Table 24

Loading...

Loading...