8

|

FHP560 Controller Applications Manual

Bosch Thermotechnology Corp.

Data subject to change Page____ of ____

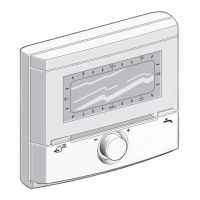

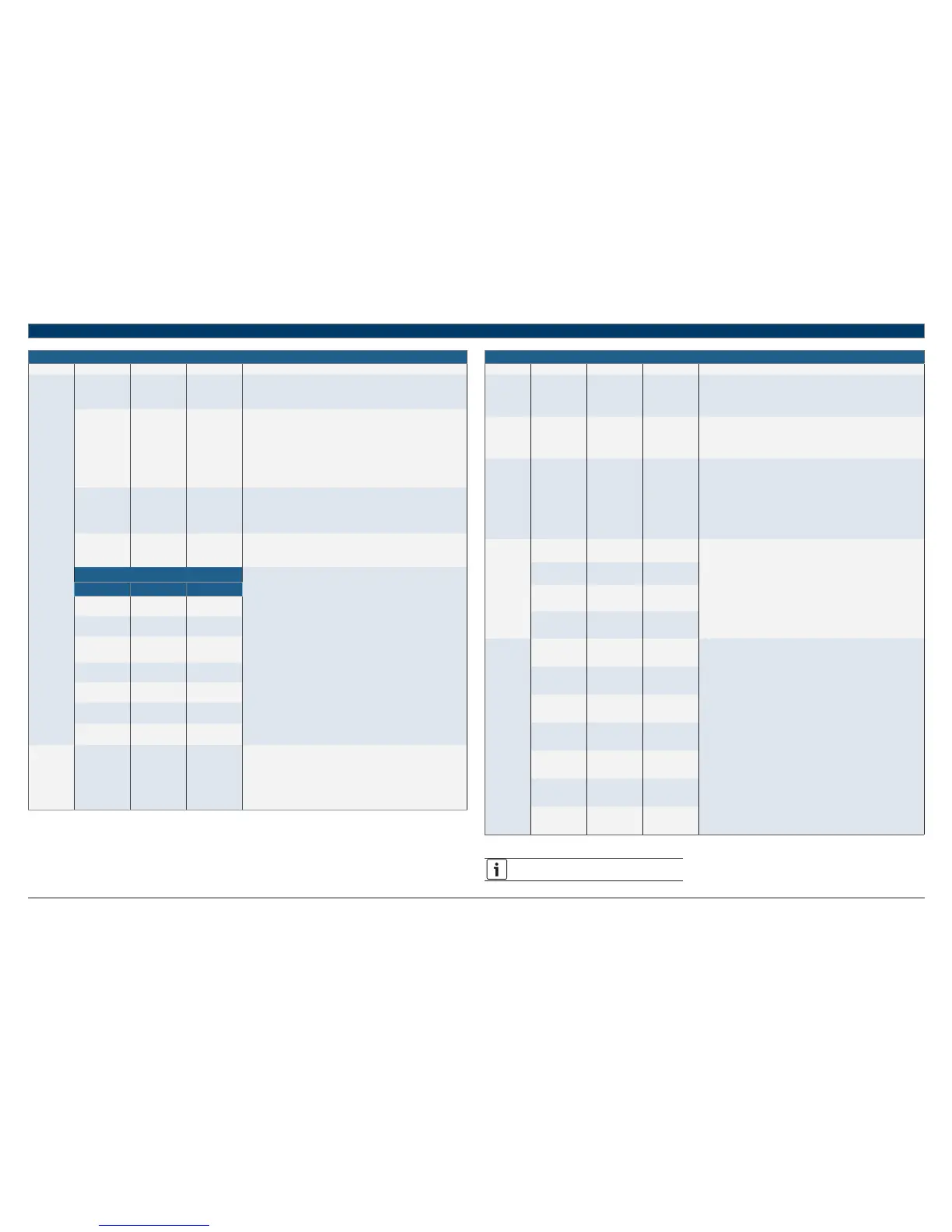

Universal Inputs

Port Inputs Accepted Signal Type Jumper Position Overview

IN-5

Smoke Detector

Switch (SDS)

Dry n/a

The normally-open contacts of a fi eld-installed smoke/fi re alarm detector may be

wired to this input to shut the heat pump unit down during an emergency. Unit

operation is ceased 5 seconds after a contact closure is detected at the input.

Pump Status

Switch (PSS)

Dry n/a

For units with a loop pump option, the status output from a factory installed

current sensor used to monitor pump operation may be connected to this input to

provide pump status during unit operation. The unit is allowed to run only when the

sensor contacts are verifi ed as closed at the input after the pump has been indexed

to run. If there's no contact closure after the loop pump has been commanded on,

the unit is not allowed to run, and an alarm is generated after 15 seconds. If the

pump fails during normal unit operation the compressors are shutdown after 20

seconds and an alarm is generated.

Mixed Air

Temperature

Sensor

Therm n/a

Select this confi guration parameter if a Mixed Air Temperature sensor is connected

in IN-5.

Input Expansion

Module (IEM)

Dry n/a

The Input Expansion Module is used in this input when multiple options that

require a binary input are required (up to 3 inputs). The combinations of these

options are limited only to the seven (7) sets of three listed below.

Input Expansion Module (IEM) Combination

These seven (7) sets of binary input combinations may be used with an IEM

connected to this input. The three (3) ports are labled (A, B, C) and must be

connected correspondingly. In situations where not all three inputs are used, the

other inputs may be disabled in the software, or the board may be jumpered if the

option requires a closed contact to function properly.

PORT 1 (A) PORT 2 (B) PORT 3 (C)

Dirty Filter Switch

(DFS)

Fan Status Switch

(FSS)

Valve End Switch

(VES)

Smoke Detector

Switch (SDS)

Fan Status Switch

(FSS)

Valve End Switch

(VES)

Dirty Filter Switch

(DFS)

Fan Status Switch

(FSS)

Differential

Pressure Switch

(DPS)

Smoke Detector

Switch (SDS)

Fan Status Switch

(FSS)

Dirty Filter Switch

(DFS)

Dirty Filter Switch

(DFS)

Fan Status Switch

(FSS)

Damper End

Switch (DES)

Smoke Detector

Switch (SDS)

Fan Status Switch

(FSS)

Secondary Drain

Pan (SDP)

Dirty Filter Switch

(DFS)

Fan Status Switch

(FSS)

Pump Status

Switch (PSS)

IN-6*

Discharge Air

Temperature

Therm n/a

A factory-installed thermistor mounted on the heat pump unit's blower housing

(air handler section) is connected to this input for all orders requiring the factory

installed DDC option. It is highly recommended that for applications requiring

a more accurate representation of the supply air temperature, a duct mounted

temperature probe be used instead to relocate the source of the discharge air

temperature just downstream of the supply air duct. If this recommendation is

followed the factory-installed thermistor may be disconnected from this input, and

replaced with the leads from the duct mounted sensor.

Table 6

* Non-confi gurable, factory assigned I/O parameter

Binary Outputs

Port Outputs Accepted Signal Type Signal Label Overview

BO-1* Fan 24VAC G

Binary Output 1 is factory reserved for the fan command (G) and is wired to the

unit terminal block in the electrical box. The fan mode may be software confi gured

either for "continuous" mode (fan is energized continuously during occupied and

night set back modes), or confi gured to run in "auto" mode (fan is energized only

during a call for heating or cooling). Continuous mode is the factory default setting.

BO-2* Reversing Valve 24VAC O

Binary Output 2 is factory reserved for the reversing valve command (O) and is

wired to the valve via the unit terminal block in the electrical box. For heat pump

units, the output is energized during a call for cooling, and remains de-energized

for heating. For straight cool units (cooling only) where no reversing valve is

installed, the output is disabled and not used.

BO-3*

Compressor

Stage 1

24VAC Y1

Binary Output 3 is factory reserved for the compressor stage 1 command (Y1) and

is connected to the UPM I board's "Y" terminal ("Y1" for dual compressor units

using the UPM II board) via the unit terminal block in the electrical box. The Y1

output is off when zone setpoint is satisfi ed and within the temperature deadband

(between heating and cooling setpoints). As the zone temperature rises above

the cooling setpoint and demand exceeds 30%, Y1 is enabled and PID methods

are employed to ensure the zone temperature is maintained within 1°F of cooling

setpoint. As the zone temperature drops below the heating setpoint and demand

exceeds 30%, Y1 is enabled and PID methods are employed to ensure the zone

temperature is maintained within 1°F of heating setpoint.

BO-4

Compressor

Stage 2

24VAC Y2

Binary Output 4 is factory defaulted for the compressor stage 2 command (Y2) and

is connected to the second stage solenoid (Y2S) for 2-step, single compressors,

or to the “Y2” terminal for dual compressor units using the UPM II board, via the

unit terminal block in the electrical box. The Y2 output is off when zone setpoint

is satisfi ed and within the temperature deadband (between heating and cooling

setpoints). The Y2 output is energized after Y1 has been on for more than 7

minutes, and the heating/cooling demand exceeds 60%.

For 1 compressor 1 stage units, Binary Output 4 may be confi gured for one of the

following options: Hot Gas Reheat (On/Off), Single Stage Auxiliary Electric Heat, or

Outside Air Damper (On/Off).

Hot Gas Re-Heat

(On/Off)

24VAC H

Fresh Air Damper

(On/Off)

24VAC D

Heating Stage 1

(Aux Heat)

24VAC W

BO-5

Hot Gas Re-Heat

(On/Off)

24VAC H

Binary Output 5 may be factory or fi eld confi gured for one of the following

options: Hot Gas Reheat (On/Off), Single Stage Auxiliary Electric Heat, Outside Air

Damper (On/Off), Condenser Water Valve, Circulating Water Pump, Economizer, or

Boilerless Electric Heat.

Fresh Air Damper

(On/Off)

24VAC D

Heating Stage 1

(Aux Heat)

24VAC W

Boilerless Control

(Aux Heat)

24VAC W

Economizer

Cooling Control

24VAC EV

Circulation Water

(Loop) Pump

24VAC P

Condenser Water

Valve

24VAC CV

Table 7

* Non-confi gurable, factory assigned I/O parameter

All I/Os must be selected/confi gured in the software or

over a BAS network.

Loading...

Loading...