12

2

2

Inspect and Repair

Inspect Cylinder Head

NOTE: Be sure all gasket material is removed from

surfaces before checking. Use a gasket scraper if

necessary.

1. Inspect cylinder head for cracks or damage.

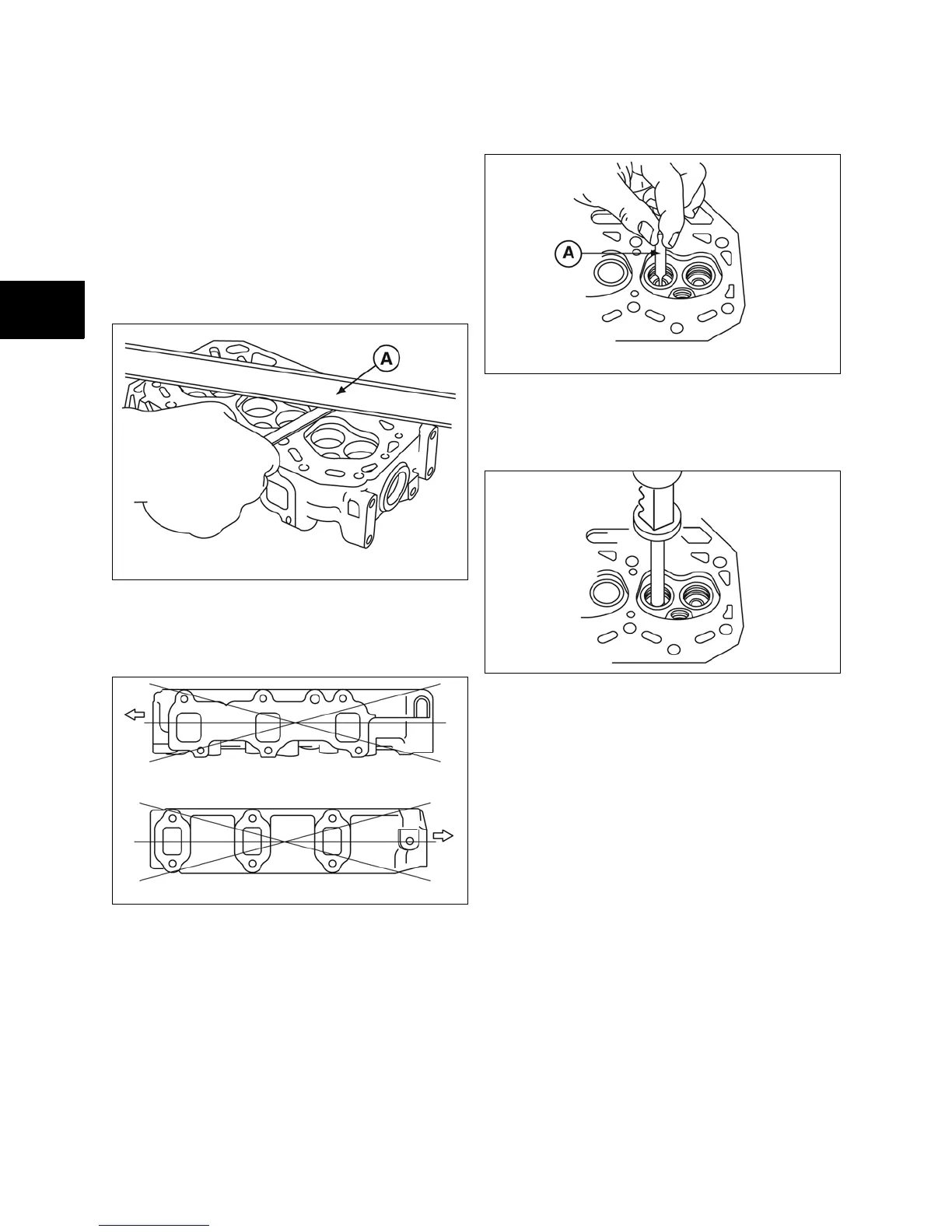

2. Use a straight edge (A, Figure 12) to check

cylinder head lower surface for distortion.

Figure 12

3. If mounting surfaces are distorted more than

0.1 mm (0.004 in), the cylinder head must be

replaced (Figure 13).

Figure 13

NOTE: It is not recommended that cylinder head

mounting surfaces be resurfaced.

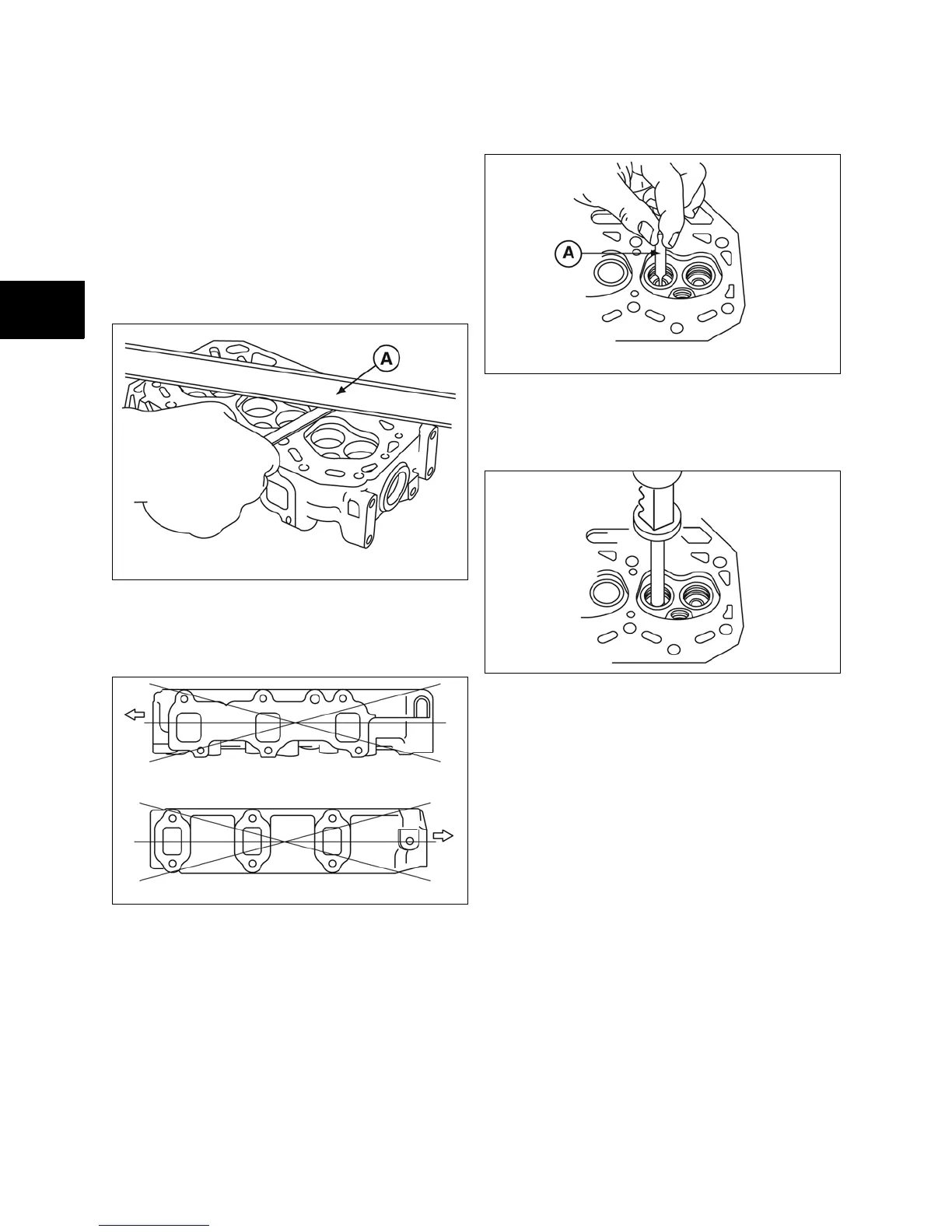

4. Inspect intake and exhaust manifold

mounting surfaces in the same manner. Use

same specifications as cylinder head.

5. Inspect valve guide bushing for damage.

Check valve guide bushings for wear using

Reject Gauge #19382, (A, Figure 14).

• Replace if damaged or if reject gauge

enters valve guide.

Figure 14

6. Use Bushing Driver #19367, and press out

valve guide bushing from combustion

chamber (Figure 15).

Figure 15

7. Check valve guide bushing OD. Then

compare with the following specifications:

• Standard Bushing OD: 11.05 mm (0.435

in.)

• Replacement Bushing OD: 11.08 mm

(0.4362 in.)

8. If bushing OD measurement indicates that a

replacement bushing has already been

installed, the cylinder head must be replaced.

9. Using Bushing Driver #19416, press in new

valve guide bushing until tool bottoms on

cylinder head (Figure 16).

Loading...

Loading...