48

7

7

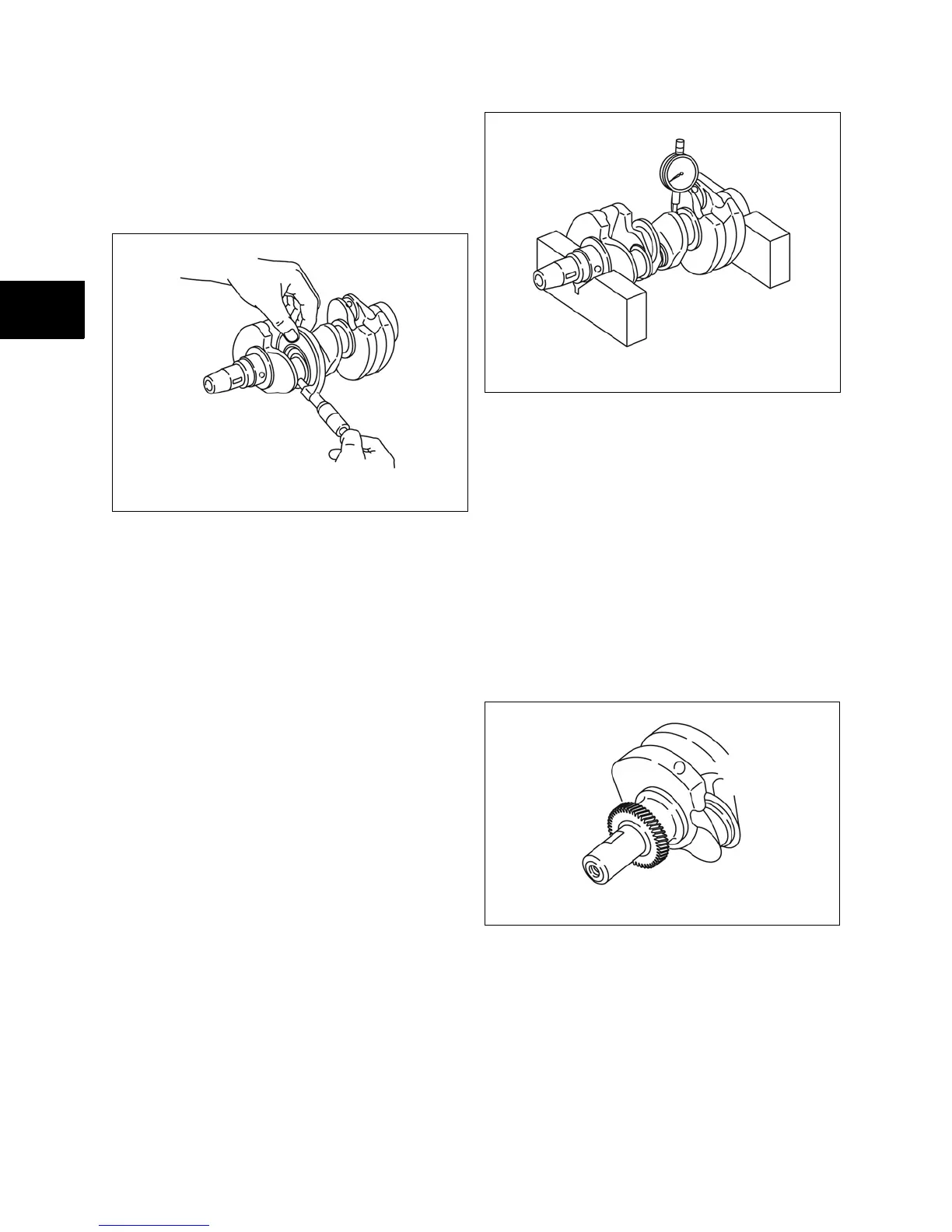

Inspect Crankshaft

1. Inspect crankshaft journals for grooves or

signs of scoring. If found, crankshaft must

be re-ground or replaced.

2. Check the main bearing and crankpin

journals for wear and taper (Figure 1).

Figure 1

• Standard Size (Main) - 1.6525 - 1.6535 in.

(41.976 - 42.000 mm)

• Standard Size (Crankpin) - 1.4557 - 1.4567

in. (36.976 - 37.000 mm)

• Maximum out of round and taper - 0.0008

in. (0.02 mm)

3. If crankshaft journals are not within

specification, the crankshaft may be re-

ground and 0.010 in. (0.25 mm) undersize

bearings installed. See illustrated parts list for

part numbers.

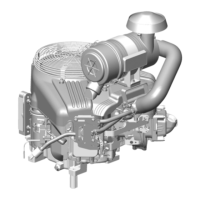

4. Check the crankshaft for run-out at #3 main

bearing journal (Figure 2).

Figure 2

• Maximum Run-out - 0.0023 in. (0.06 mm)

NOTE: If run-out exceeds specification shown, the

crankshaft must be replaced.

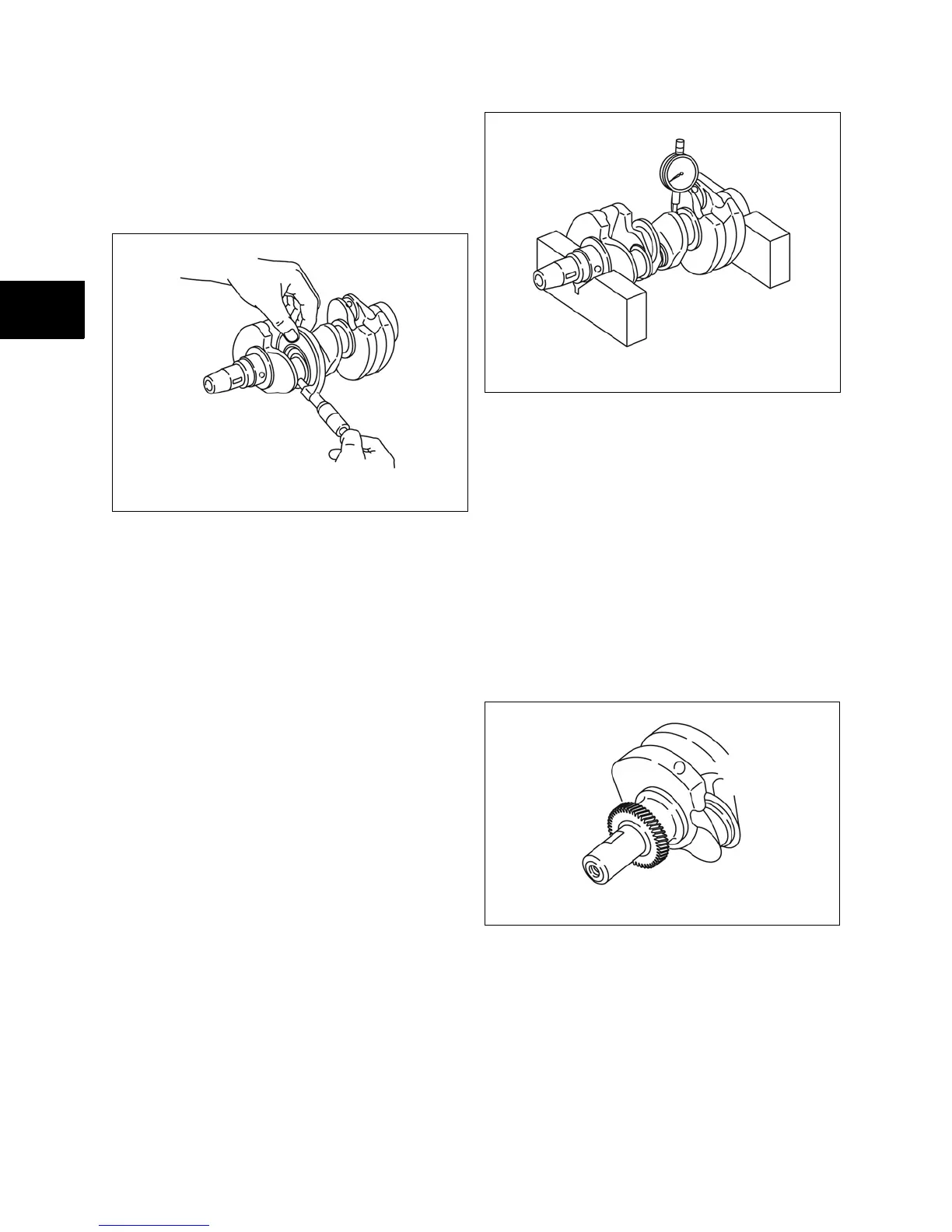

5. Check crankshaft timing gear teeth for

damage (Figure 3). If timing gear teeth are

damaged or worn, the crankshaft must be

replaced.

NOTE: See Section 3 for procedure to check

crankshaft timing gear for wear.

Figure 3

Loading...

Loading...