131

11

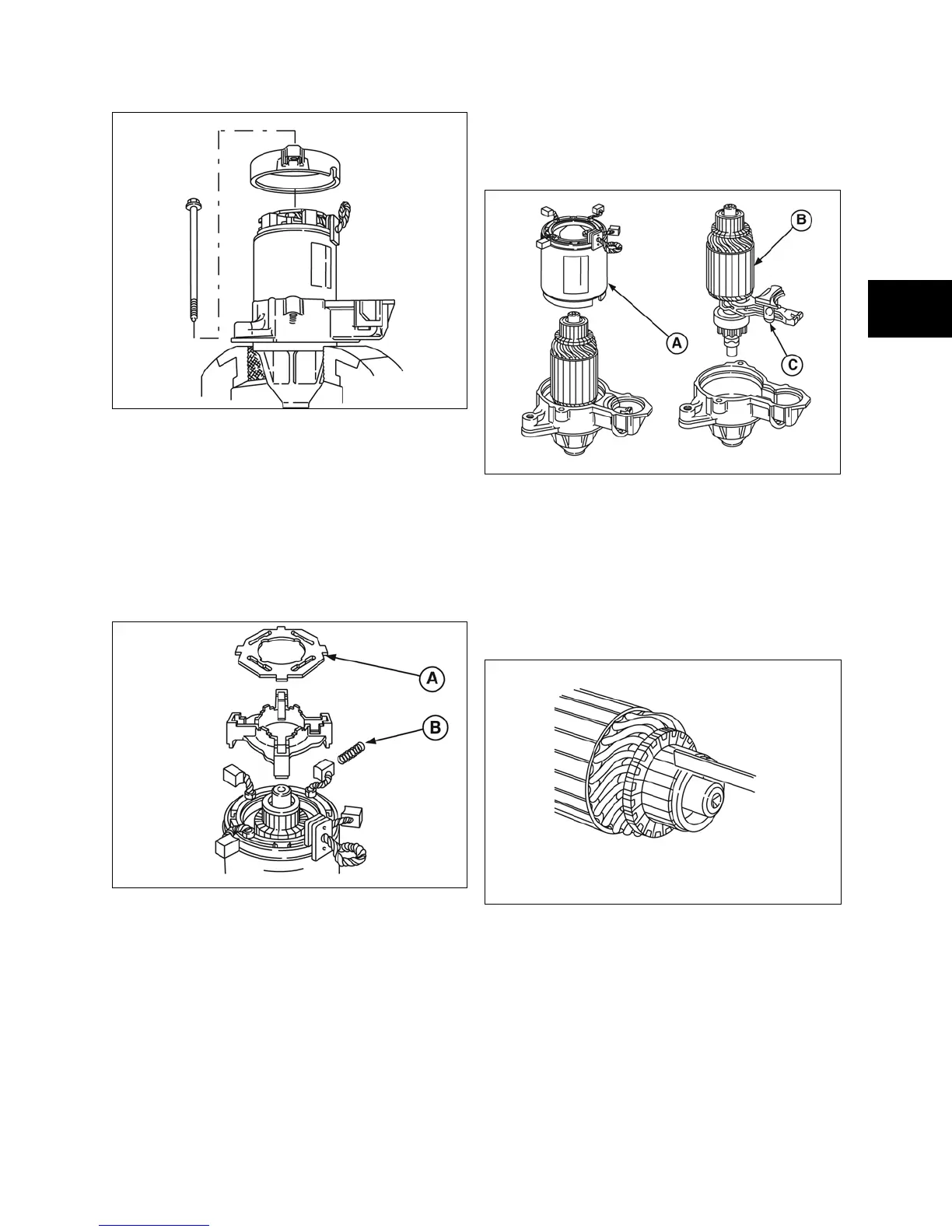

Figure 59

Inspect Armature Commutator

The armature commutator may be cleaned with fine

sandpaper (#300-500 grit). DO NOT use emery

cloth. Commutator may be machined to no less

than 27.0 mm (1.062 in.).

Slots between the commutator bars should be

cleaned with a hack saw blade after cleaning and

machining (Figure 60).

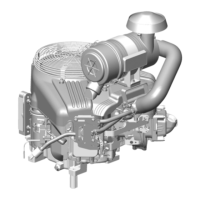

Figure 60

The armature should be checked for shorts with a

growler.

Inspect Brushes

Minimum brush dimension is 2.95 in. (7.5 mm)

(Figure 61). If brushes are worn less than

specification, replace the brushes or stator housing.

Figure 61

1. Use a digital multimeter to check for

continuity between field coil wire and

brushes (Figure 62).

2. Set the meter to the +))))) position.

3. Attach either meter test lead to field coil wire.

4. Contact first one, then other brush with other

test lead.

Figure 62

• Meter should make continuous tone

(continuity).

• If meter does not make a tone, (no

continuity), replace starter housing.

5. Attach either test lead to starter housing

(Figure 63).

6. Contact first one, then other brush with other

test lead.

Loading...

Loading...