1. General information

1.1

Application area

These operating instructions are intended for the water ring pumps of the 2BV2, 2BV5, 2BV6

series. The 2BV2 and 2BV5 pumps are single-stage pumps and are directly connected to the motor.

The 2BV6 series pumps are cantilevered and are supplied with an explosion-proof motor.

Before installing the equipment, be sure to familiarize the technician with the contents of

this manual, as it contains basic information on the installation, use and repair of the pump. It is

advisable to ensure that the technicians installing the pump have easy access to the manual

throughout the installation.

1.2

How it works

The 2BV pumps do not take up much space, are directly connected to the motor and are quite

compact. To install them, simply place them on a flat, horizontal surface and secure them. There is no

need to build a frame for them.

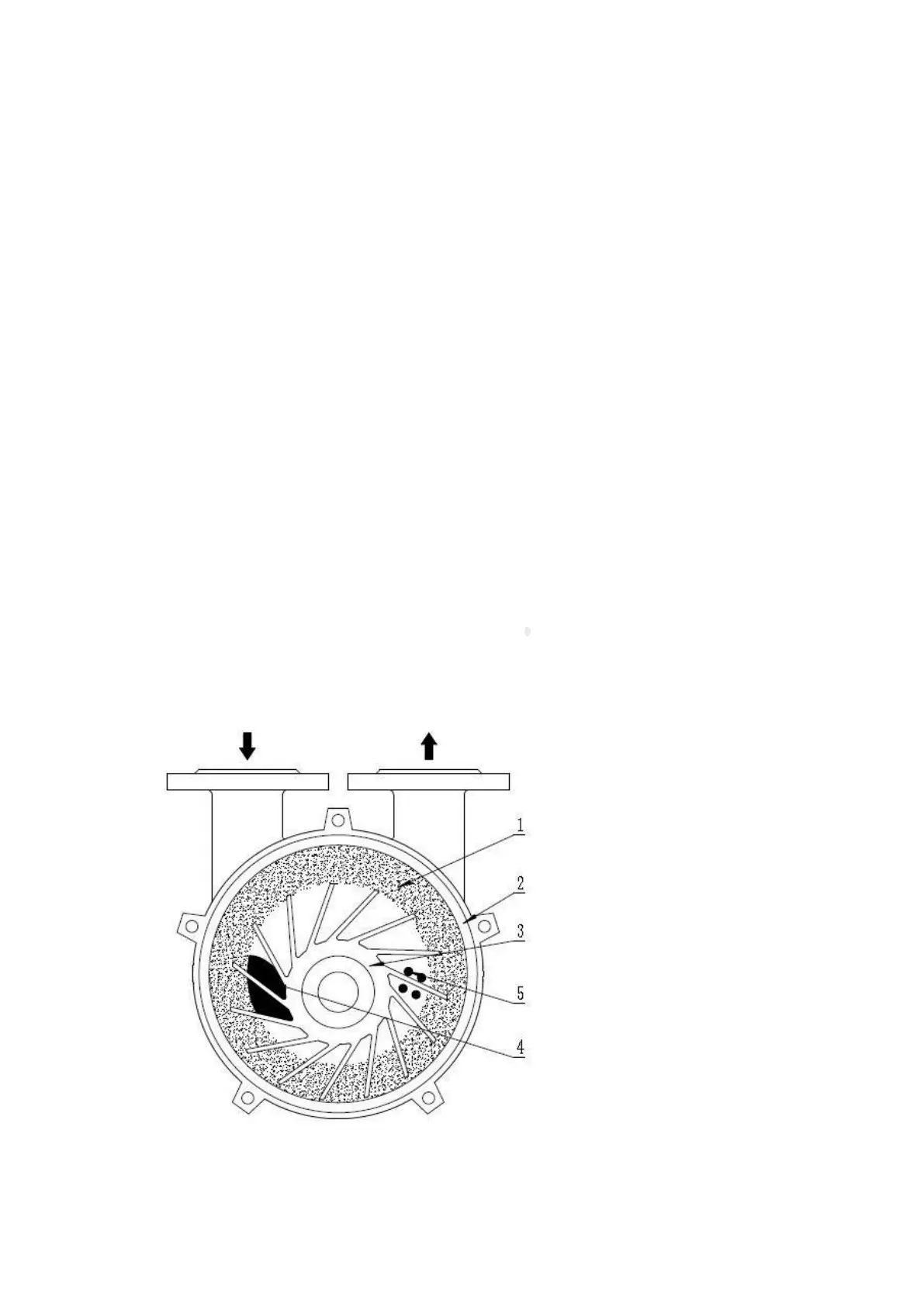

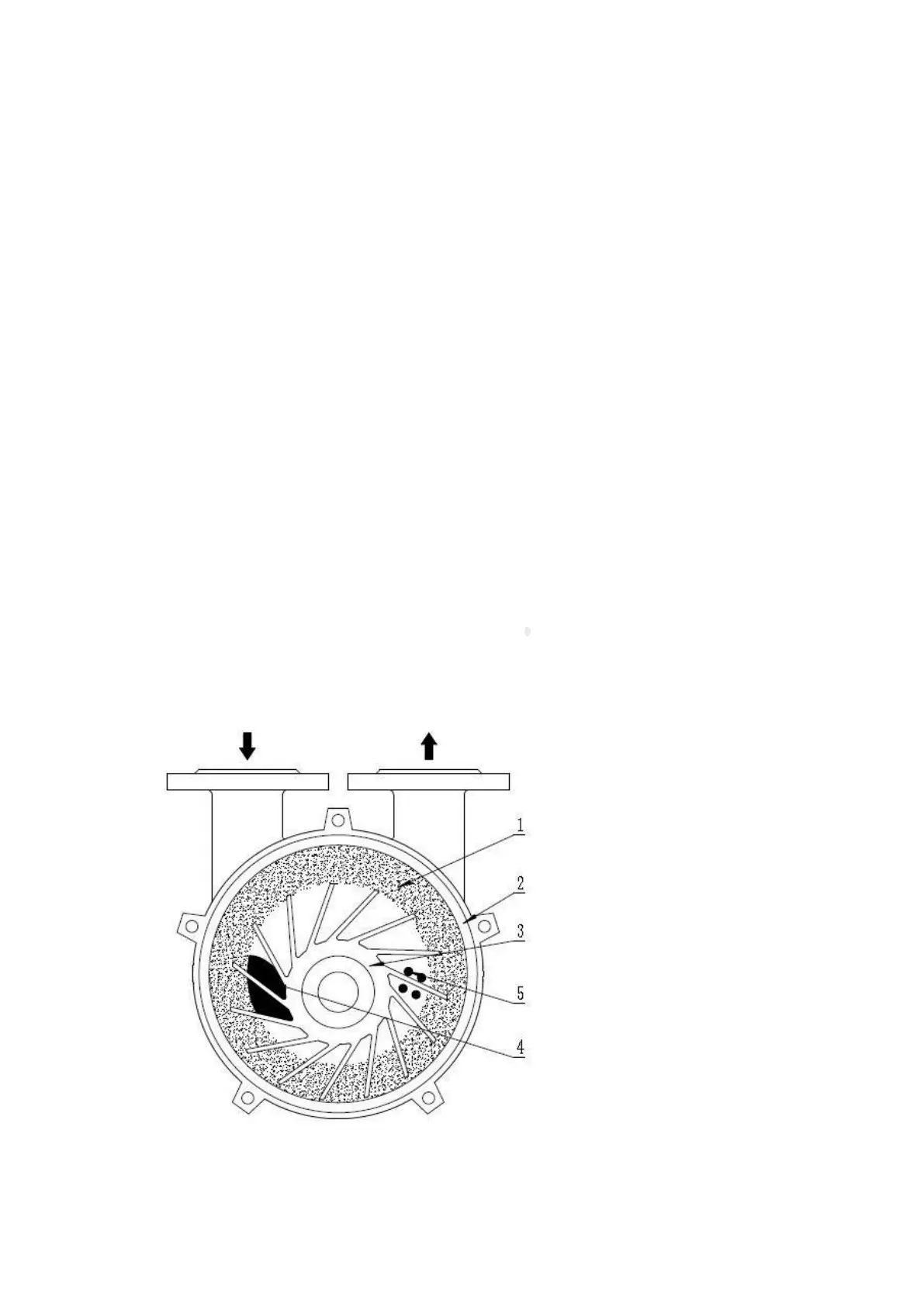

The 2BV series pumps operate on the water-ring principle. The impeller (impeller) in such a pump

is mounted eccentrically inside the working chamber - that is, its axis of rotation does not coincide with

the center of the chamber. After starting the pump, the working fluid

is spun by the impeller and, under the influence of centrifugal force, forms a liquid ring along the walls

of the working chamber. The impeller blades are partially immersed in the liquid. Since the impeller is

mounted eccentrically and the thickness of the water ring is the same around the entire perimeter of the

working chamber, the volume of air between a single pair of impeller blades and the working fluid

changes during each revolution.

When this volume increases, air is sucked in through the inlet valve. When it decreases, the gas is

pushed out through the exhaust valve.

Figure 1 shows a schematic diagram of the water ring pump (view from the pump cover)

Figure 1:

1) working fluid

ring;

2) the wall of the

working

chamber;

3) impeller

(impeller);

4) air inlet;

5) air outlet.

Loading...

Loading...