which is then expelled with the pumped air through the outlet. As the working fluid leaves the

pump, fresh fluid is added to it.

After pre-filling, the 2BV pumps can be started and automatically draw up the process

liquid. This requires sufficient process fluid to be available when the pump starts.

3.1.3.2

Separator and partial recirculation

This delivery method helps to save some water. Part of the working fluid settles in the

separator and flows directly to the pump, without any cooling. In this case, part of the liquid is lost

to evaporation and is replaced with fresh liquid. All connection sets are supplied with the

separators.

3.1.4

Separator

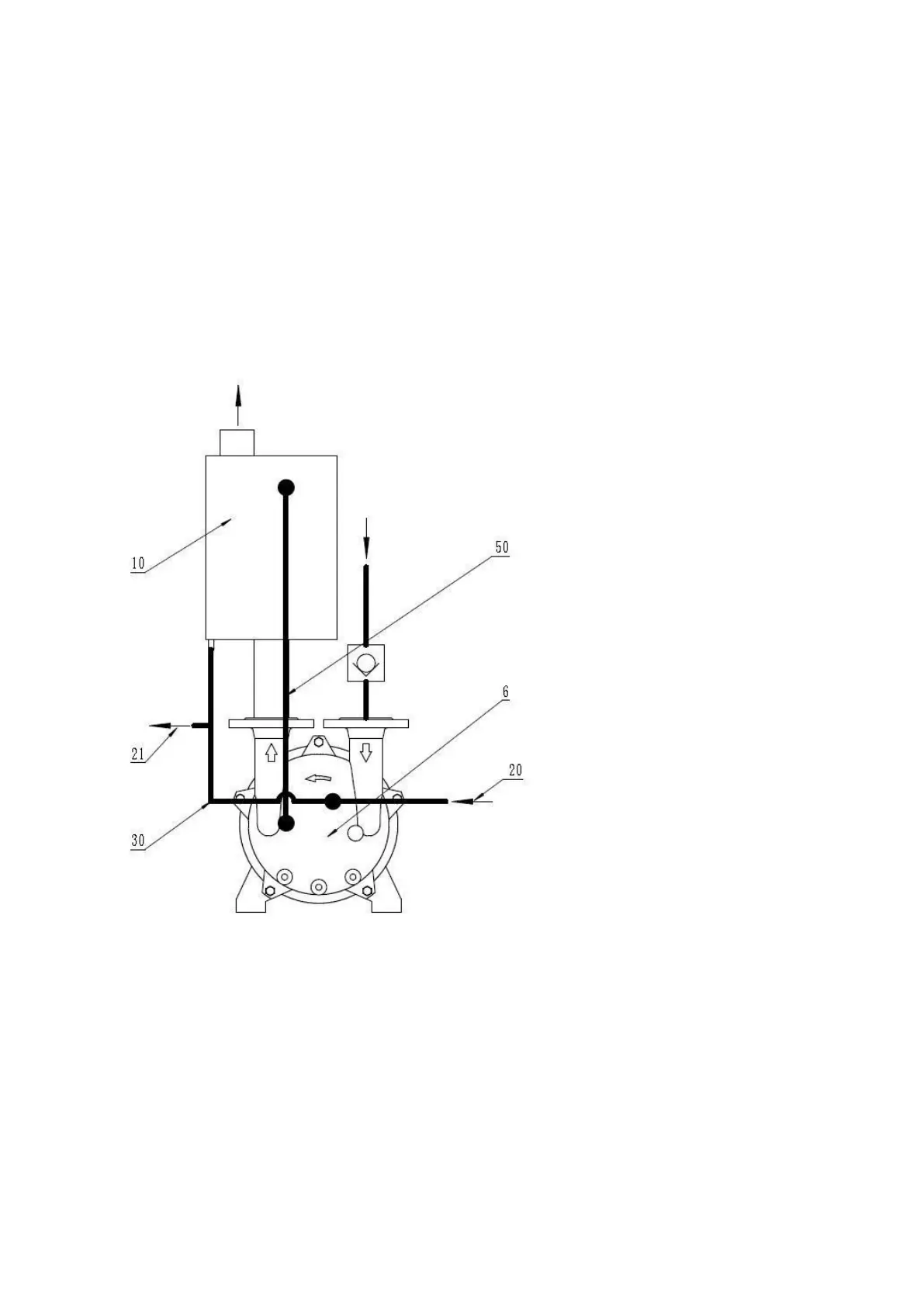

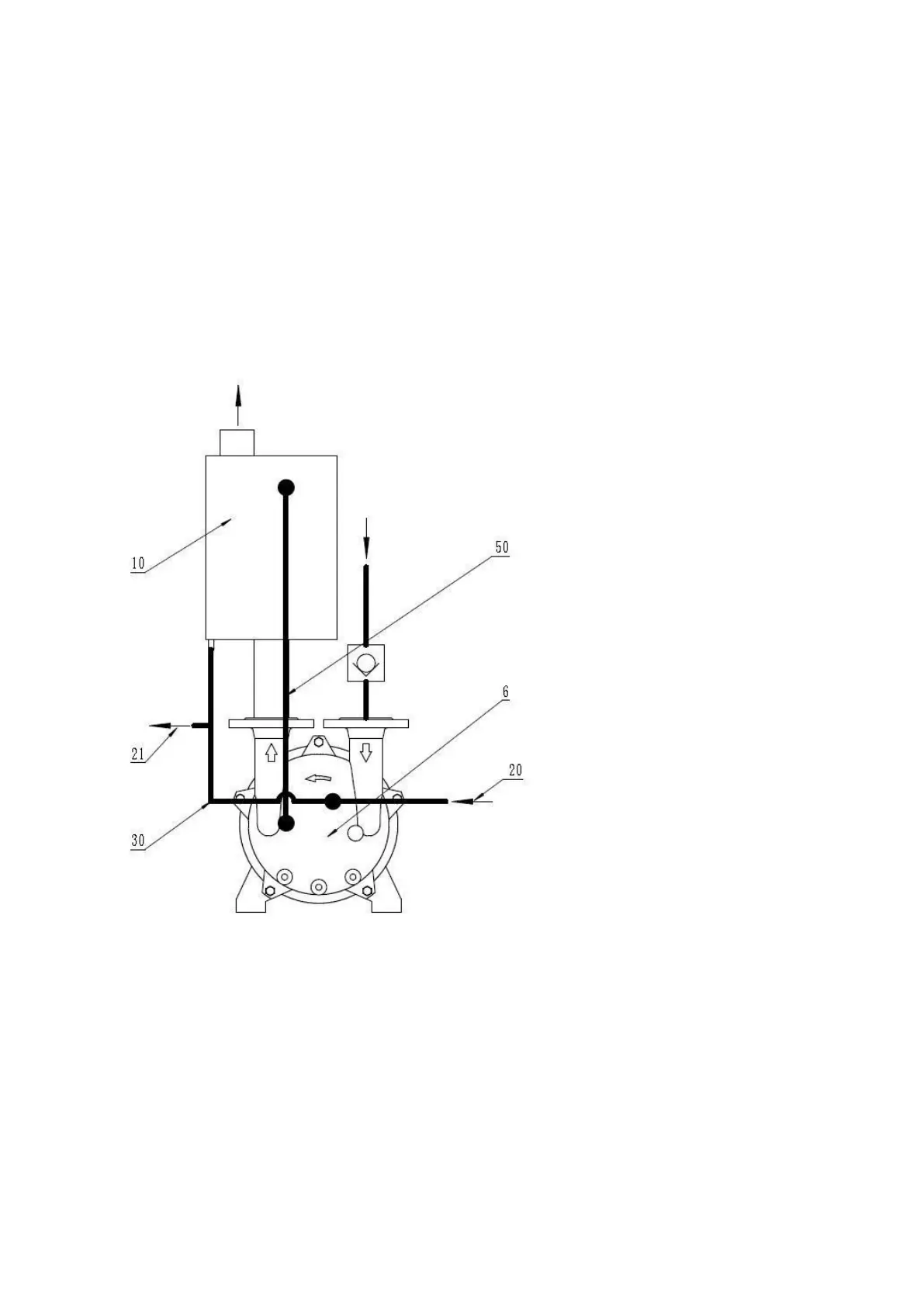

Figure 4:

6) vacuum pump;

10) separator;

20) supply of

working fluid;

21) draining the working fluid;

30) working fluid circulation

line;

50) cavitation protection line.

The separator is designed to separate the liquid from the pumped gas. It allows the

process fluid to be recycled, which significantly reduces its consumption (see Figure 4). The

separator is supplied as an accessory with all necessary connections.

If cavitation protection is required, a safety valve is connected between the separator and

the pump casing.

3.1.5

Check valve

To prevent backflow and liquid from entering the vacuum network, we recommend

installing a check valve on the suction side.

Loading...

Loading...