30

Fluid installation

The length of this control line should be adapted to the actuator

size because the clearance volumes caused by the control

line can have a negative influence on the control properties.

The following is the case: the smaller the actuator, the more

sensitively the control system reacts to the length of the

pneumatic control line.

Procedure:

Control functions A and B (single-acting actuators):

→ Connect the working connection A1 or A2

4)

of the positioner

Type 8791 or Type 8792/8793 to the connection (1) using a

hose.

→ Attach the exhaust airline or a silencer to the connection (3

1

).

4)

in line with desired safety position (see operating instructions Type 8791

or Type 8792/8793)

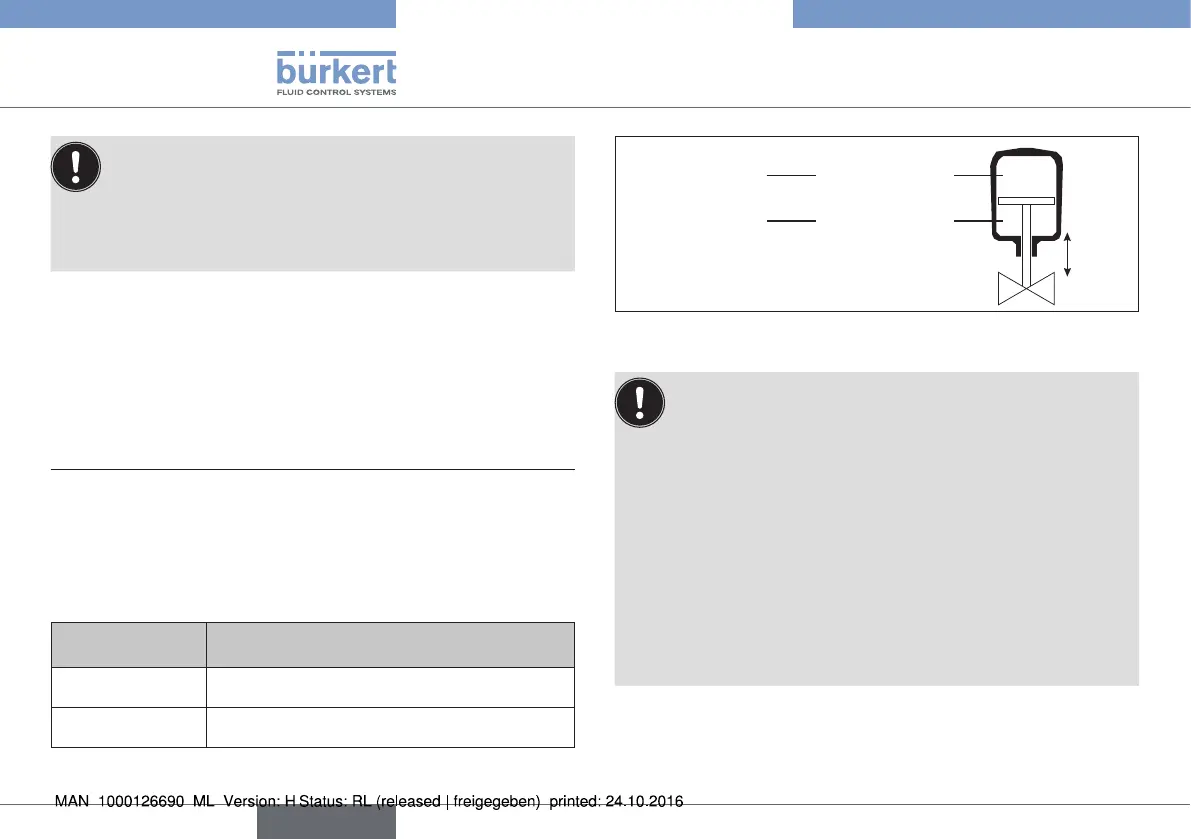

Control function I (double-acting actuators):

→ Connect working connections A1 and A2 to the respective

chambers of the Remote Sensor.

Connection for

Remote Sensor

Actuator

3

1

upper chamber of the actuator

1 lower chamber of the actuator

Tab. 5: Pneumatic connection - control function I

up

down

lower chamberConnection 1

upper chamberConnection 3

Fig. 32: Pneumatic connection - control function I

Caution: (Exhaust air concept):

In compliance with degree of protection IP67, an exhaust

air line must be installed in the dry area (control function A

and B).

Keep the adjacent supply pressure always at least 0.5 –

1 bar above the pressure which is required to move the

actuator to its end position. This ensures that the control

behavior is not extremely negatively affected in the upper

stroke range on account of too little pressure difference.

During operation keep the fluctuations of the pressure supply

as low as possible (max. ±10 %). If fluctuations are greater,

the control parameters measured with the X.TUNE function

are not optimum.

english

Type 8798

Loading...

Loading...