27

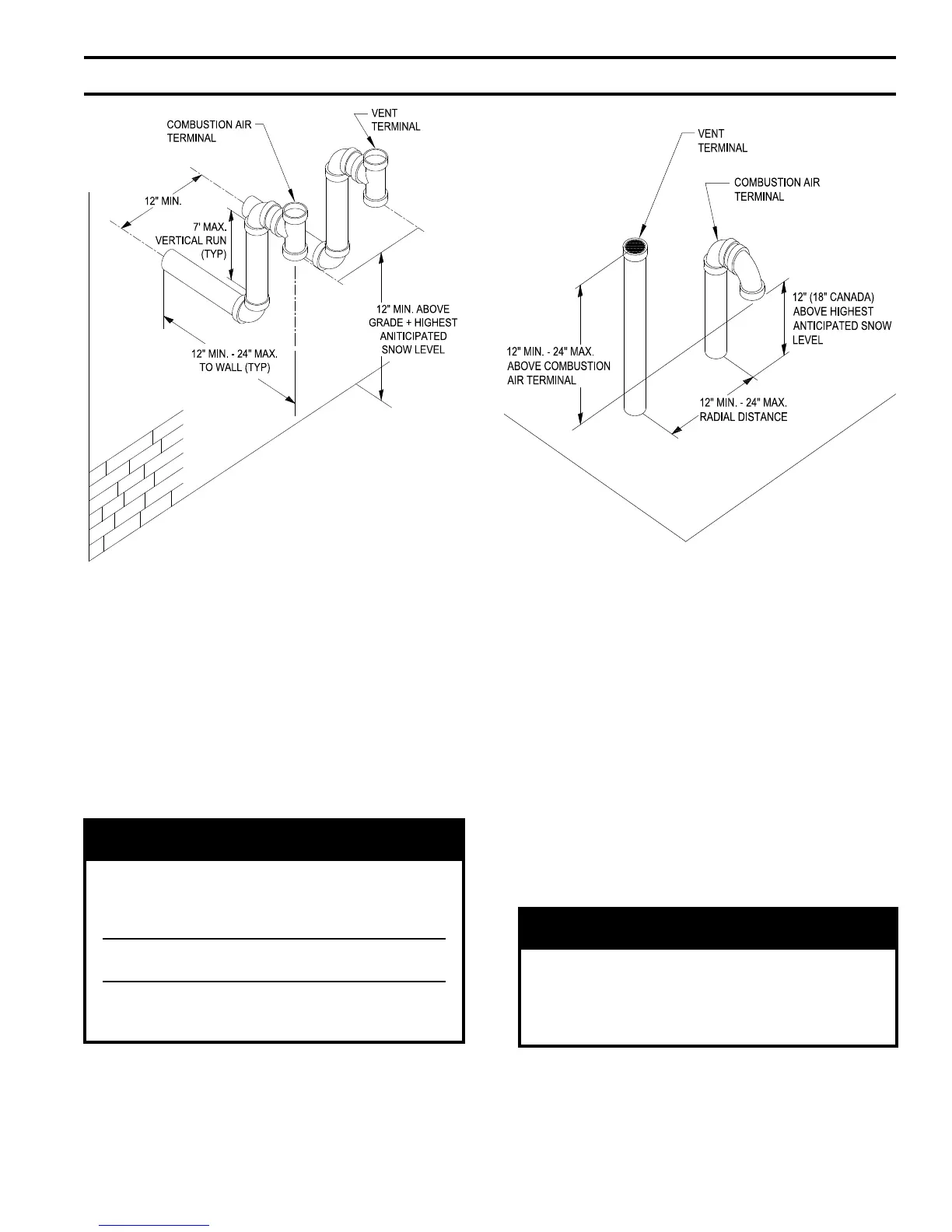

• Install maximum vertical run of seven (7)

feet of Schedule 40 PVC vent pipe. See

Figure 10.

• At top of vent pipe length install another

PVC 90° elbow so that elbow leg is

opposite the building’s exterior surface.

• Install Rodent Screen and Combustion

Air Terminal (supplied with boiler), see

Figure 9 for appropriate conguration.

• Brace exterior piping if required.

WARNING

All CPVC supplied with the vent kit must be

used prior to connection of the vent system to

this terminal. If the vent system is too short

to permit this, do not use this terminal.

Do not operate boiler without the rain cap in

place.

Methods of securing and sealing terminals

to the outside wall must not restrain the

thermal expansion of the vent pipe.

7.

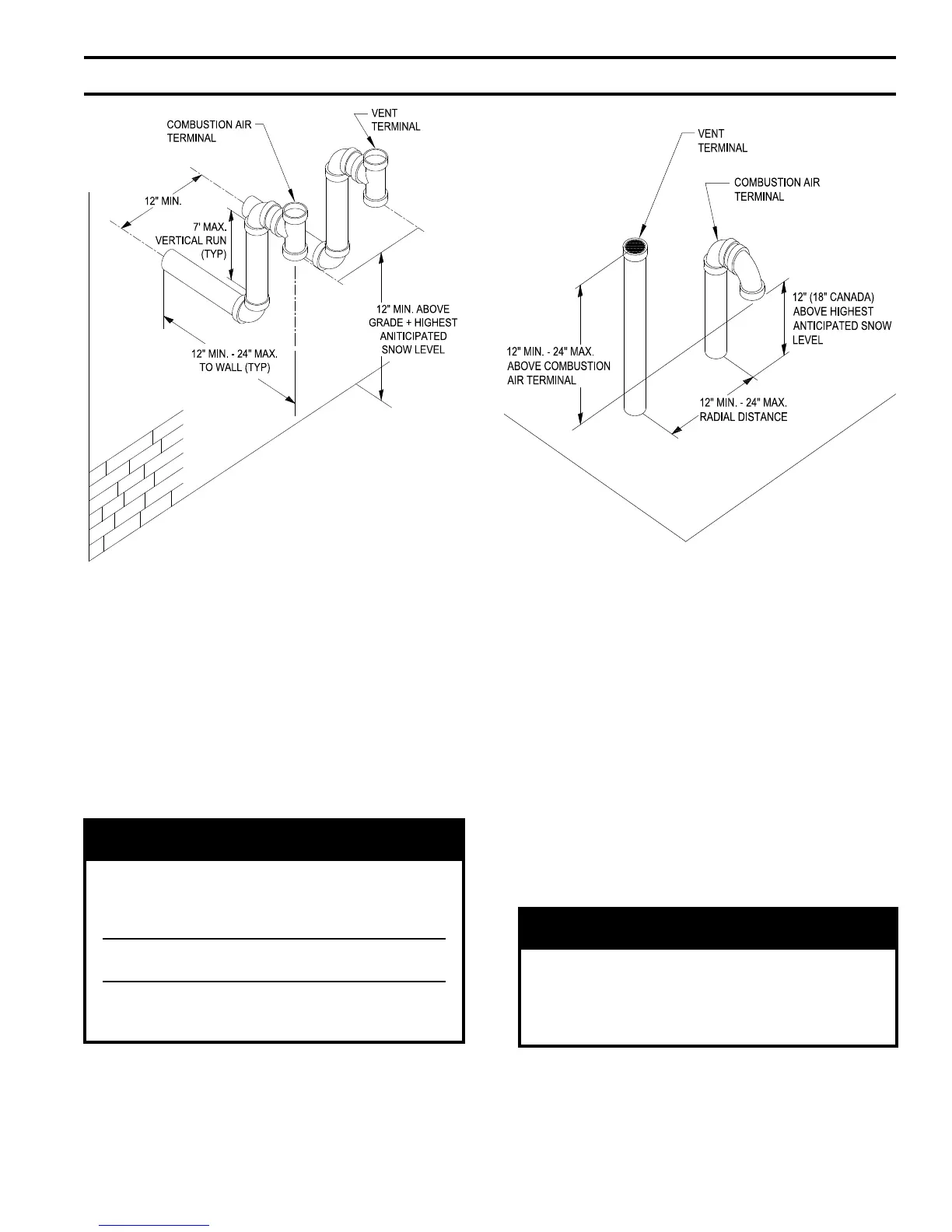

Vertical Vent Termination

a. Standard Two-Pipe Termination

Refer to Figures 7, 9, 11 and 12.

Figure 11: Direct Vent - Vertical Terminations

Figure 10: Direct Vent - Optional Sidewall

Snorkel Terminations

i. Vent Piping

•

Install re stops where vent passes

through oors, ceilings or framed walls.

The re stop must close the opening

between the vent pipe and the structure.

• Whenever possible, install vent straight

through the roof. Refer to Figures 11 and

12.

- Size roof opening to maintain

minimum clearance of 1" from

combustible materials.

- Extend vent pipe to maintain minimum

vertical and horizontal distance of

twelve (12) inches from roof surface.

additional vertical distance for

expected snow accumulation. Provide

brace as required.

CAUTION

Vertical venting and combustion air roof

penetrations (where applicable) require the use

of roof ashing and storm collar, which are not

supplied with boiler, to prevent moisture from

entering the structure.

- Install storm collar on vent pipe

immediately above ashing. Apply

Dow Corning Silastic 732 RTV

Sealant between vent pipe and storm

collar to provide weather-tight seal.

IV. Venting (continued)

Loading...

Loading...