9

NICE - MIRIAM - CRISTAL - PRETTY - KRISS - MARY - TECNA - EVO

EN

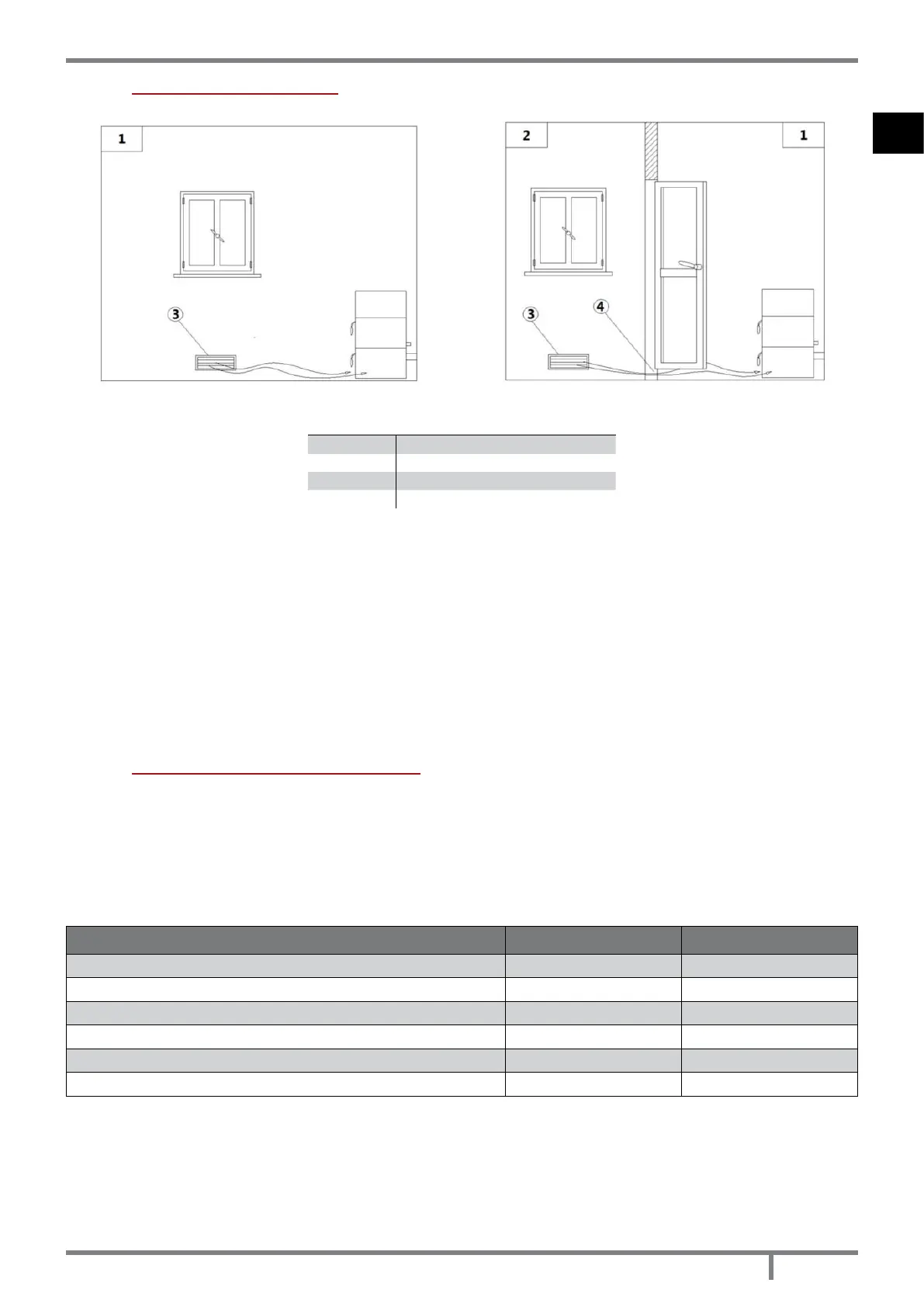

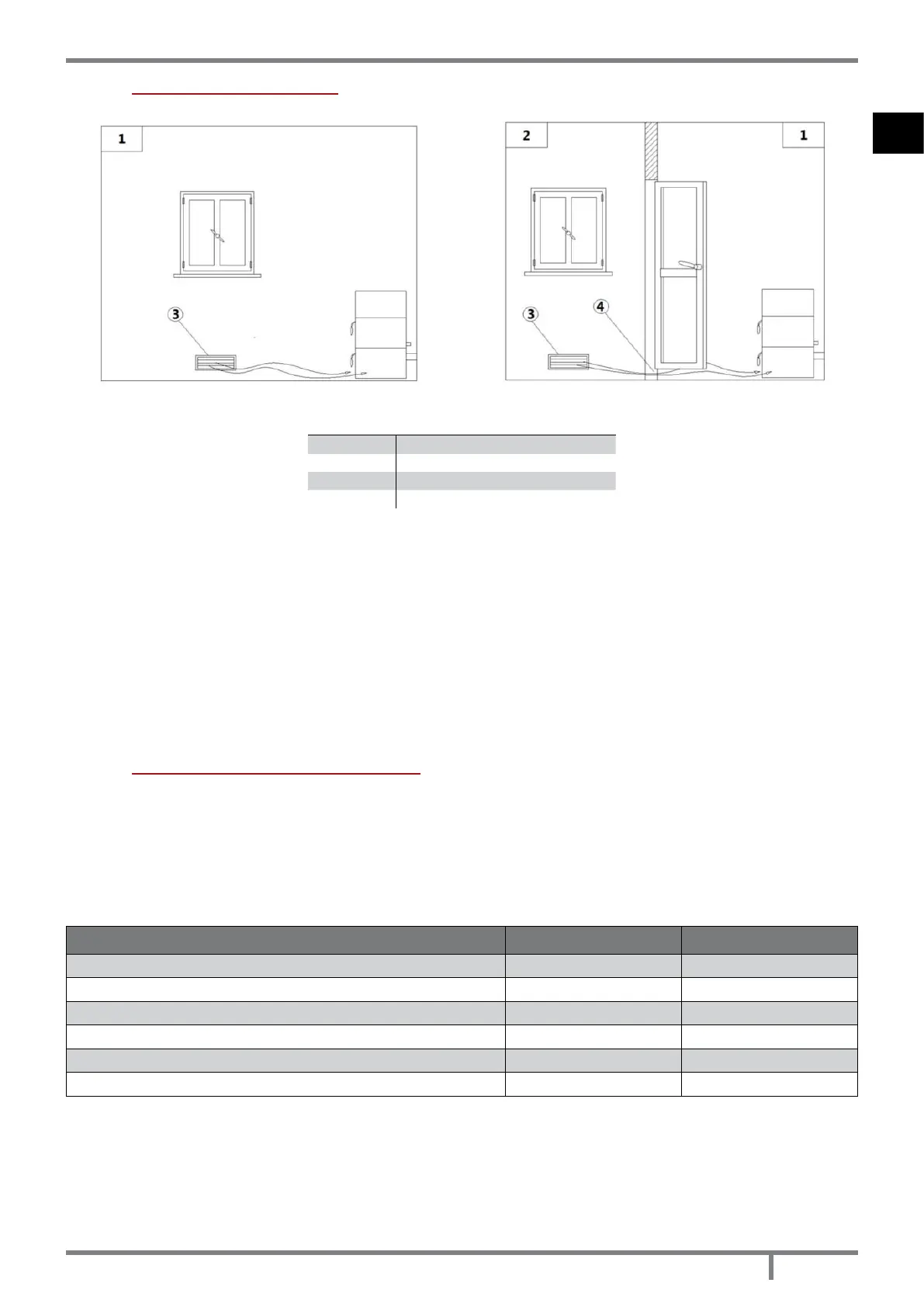

8.8 EXTERNAL AIR INLET

Fig. 6 - Direct air inow Fig. 7 - Indirect air inow

LEGEND Fig. 6 page 9|Fig. 7 page 9

1 Room to ventilate

2 Adjacent room

3 External air inlet

4 Cleft under the door

• The room must be endowed with an external air recycling for a good climate in your ambient.

• The air inow from outside to the inner occurs directly, through an opening on the external wall of the room

(see Fig. 6 page 9); otherwise it occurs indirectly by air suction from rooms adjacent to the one to ventilate

(see Fig. 7 page 9).

• Bedrooms, garages, and store of ammable materials are excluded.

• The air inlet should have a total net surface of 80 sqcm

2

: the aforesaid surface is to widen if inside the room

there are other activated appliances (for example: electric ventilators for foul air suction, cooker hoods, other

stoves, etc...) which depress the environment.

• At switched on appliance it is necessary to check that the pressure fall between the room and the outside

does not exceed 4,0 Pa value: if necessary widen the air inlet (EN 13384).

• The air inlet must be realized at a height close to the oor with an external grid against birds. In such a way it

cannot be obstructed by any object.

• In case of installation with sealed-chamber the air inlet is not necessary.

8.9 CHIMNEY FLUE CONNECTION

Your pellet stove works through a fume draught forced by a fan. It is obligatory to check that all pipes are

realized in compliance with the following regulation on material selection: EN 1856-1, EN 1856-2 e UNI/TS 11278.

All must be effected by specialized personnel or companies as provided by UNI 10683:2012.

• The connection between the appliance and the chimney ue should be short in order to favor the draught

and to avoid condensation in the pipes.

• The fume conduit should be equivalent or longer than the outlet joint ones (Ø 80 mm).

• Some stove models are endowed with a lateral and/or back exhaust. Check that the unused exhaust is

sealed with the plug given with standard equipment.

SYSTEM TYPE Ø80 mm PIPE Ø100 mm PIPE

Minimum vertical length 1,5 mt 2 mt

Maximum length (with 1 union) 6,5 mt 10 mt

Maximum length (with 3 unions) 4,5 mt 8 mt

Maximum number of unions 3 3

Level section (minimum inclination 3%) 2 mt 2 mt

Installation at a height above 1200 m a.s.l. NO Obligatory

• Use a plate pipe for stoves of Ø80 mm or Ø100 mm depending on the type of system and with silicone gaskets.

• It is forbidden to use metal, bre cement or aluminium exible pipes.

• For change of direction it is obligatory always to use a union (with angle > 90°) with inspection plug which

enables an easy periodic cleaning of the pipes.

• Please assure you that after the cleaning the inspection plugs are sealed with its efcient gasket.

• It is forbidden to connect more appliances to the same fume conduit.

• It is forbidden to convey in the same fume conduit exhausts from overhanging cooker hoods.

• It is forbidden to exhaust ue gases directly from the wall towards the outside and closed spaces also at open

Loading...

Loading...