6

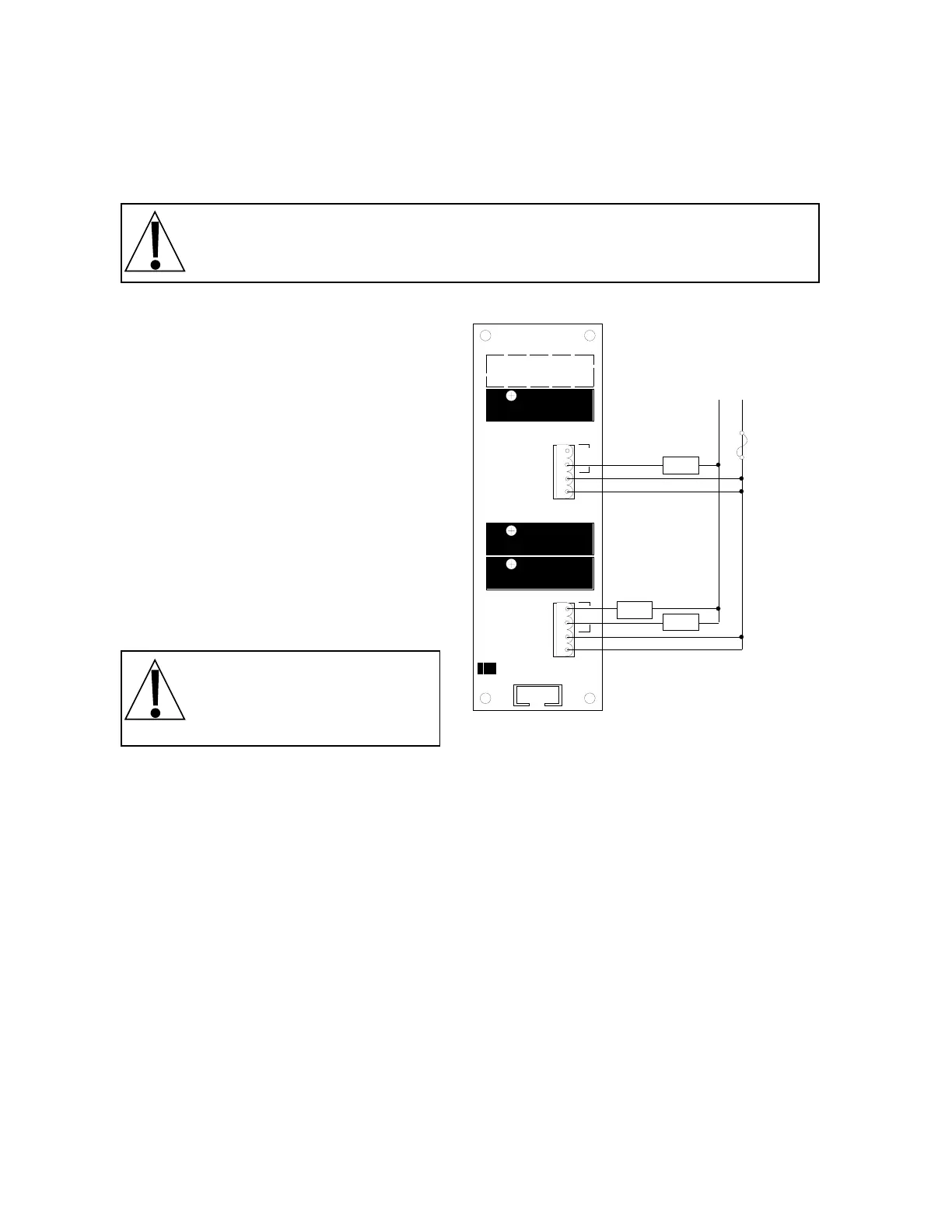

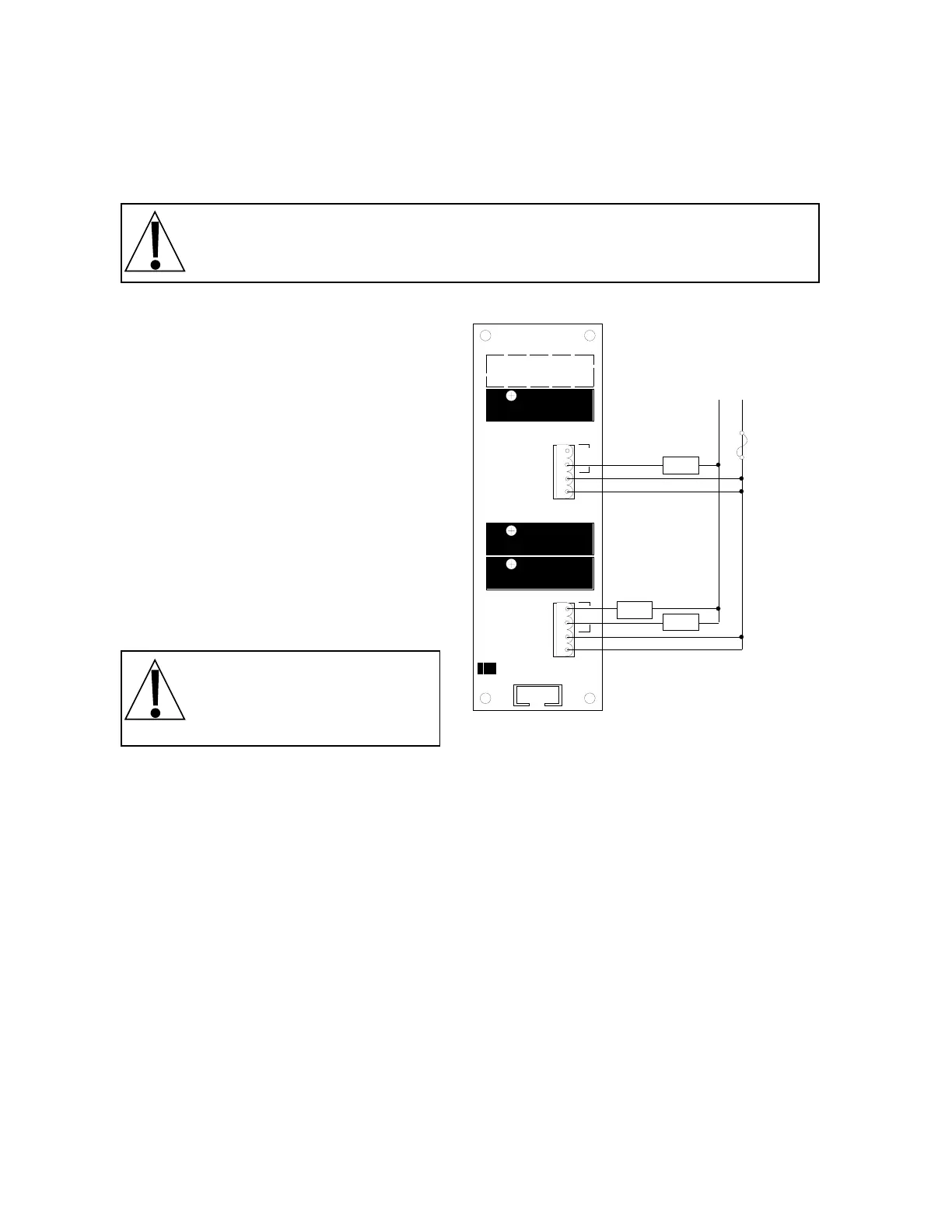

To connect the control cable to the preset weight comparator/checkweigher logic level outputs, first

loosen the gland connector located on the bottom of the 708 on the right side. Refer to Figure No. 7

for the exact location of this connector. Slip the cable through this connector and into the enclosure.

Remove 2 inches of the cable insulating jacket then 1/4 inch of insulation from each of the internal

wires. Refer to Figure No. 8. Make the proper terminations on terminal block P10. To terminate a

wire, first press down on the terminal block release bar, insert the wire into the terminal and remove

pressure from the release bar locking the wire in place.

NOTE: After all terminations have been made, remove the excess cable from within the

instrument enclosure and securely tighten each of the cable gland connectors. Do not

over-tighten these connectors but make certain they are snug. DO NOT USE TOOLS

TO TIGHTEN THE CONNECTORS! Tighten only by hand.

Relay Board

The relay board is mounted to the NEMA 4X

enclosure bottom or in an external junction

box for use with the desktop enclosure.

The individual relays can be configured to be

on (closed) or off (open) at weights under the

preset weight and switch at the preset weight

from on-to-off or off-to-on by setting the under

weight condition to on or off during setup and

calibration or setup review.

EXAMPLE: Und1=on. . . PWC1 relay is on

(closed) for weights under the preset weight

and off (open) for weights equal to or over the

preset weight.

NOTE: All relays are the

normally-open type that will

open when power to the

indicator is lost.

Connect the devices to be controlled as shown in Figure No. 10.

DATA FORMAT SPECIFICATIONS

Serial Data Format

The serial data formats are defined during the setup and review operations. At these times it is

possible to select operation with a computer, remote display (scoreboard) or printer as well as

select the baud rate. Baud rates of 1200, 2400, 4800, 9600 and 19.2K baud are supported. The

data format is fixed at 8 bits with no parity and 1 stop bit.

The serial interface can be configured to operate with a printer (transmits weight data when PRINT

key is pressed), a scoreboard (continuously transmits weight data) or to a computer (transmits data

on receipt of a command from the computer). The actual selection of the mode of operation is made

during the setup and calibration of the instrument. Refer to the applicable section of this manual for

detailed information.

K4K3K2K1

L1 L1 3/7 4/8L1 L1 1/5 2/6

PWC1

PWC2

PWC3

P1

1

PWC

PWC

L2 L1

LOAD

3.0A MAX

LOAD

3.0A MAX

LOAD

3.0A MAX

8539-C062-0K

(28-240 VAC)

Not Used

Accept

L1

L1

Under/PWC2

Over/PWC1

L1

L1

Fuse

3-9 Amp

User Supplied

Figure No. 10

Loading...

Loading...