SHANDONG CARTER HEAVY INDUSTRY MACHINERY CO., LTD.

73

Caution:

a.

Always firstly disconnect the battery clips (-) away from the ground and then lastly connect it.

b.

Always keep the terminals at top to battery and the breather clean, to avoid the battery from discharging. Check if

the battery terminal is loosened or rusted. Coat the terminals with vaseline to avoid any corrosion.

Replace the battery

There is a 12V battery with one negative pole (-) grounded.

If battery cannot be charged or store any electricity, replace the battery with same model.

Replace the fuse.

If the electrical device does not work, please firstly check the fuse.

Important: please install the fuse with correct amperage, so as to prevent against burning of electrical system due to

overloading!

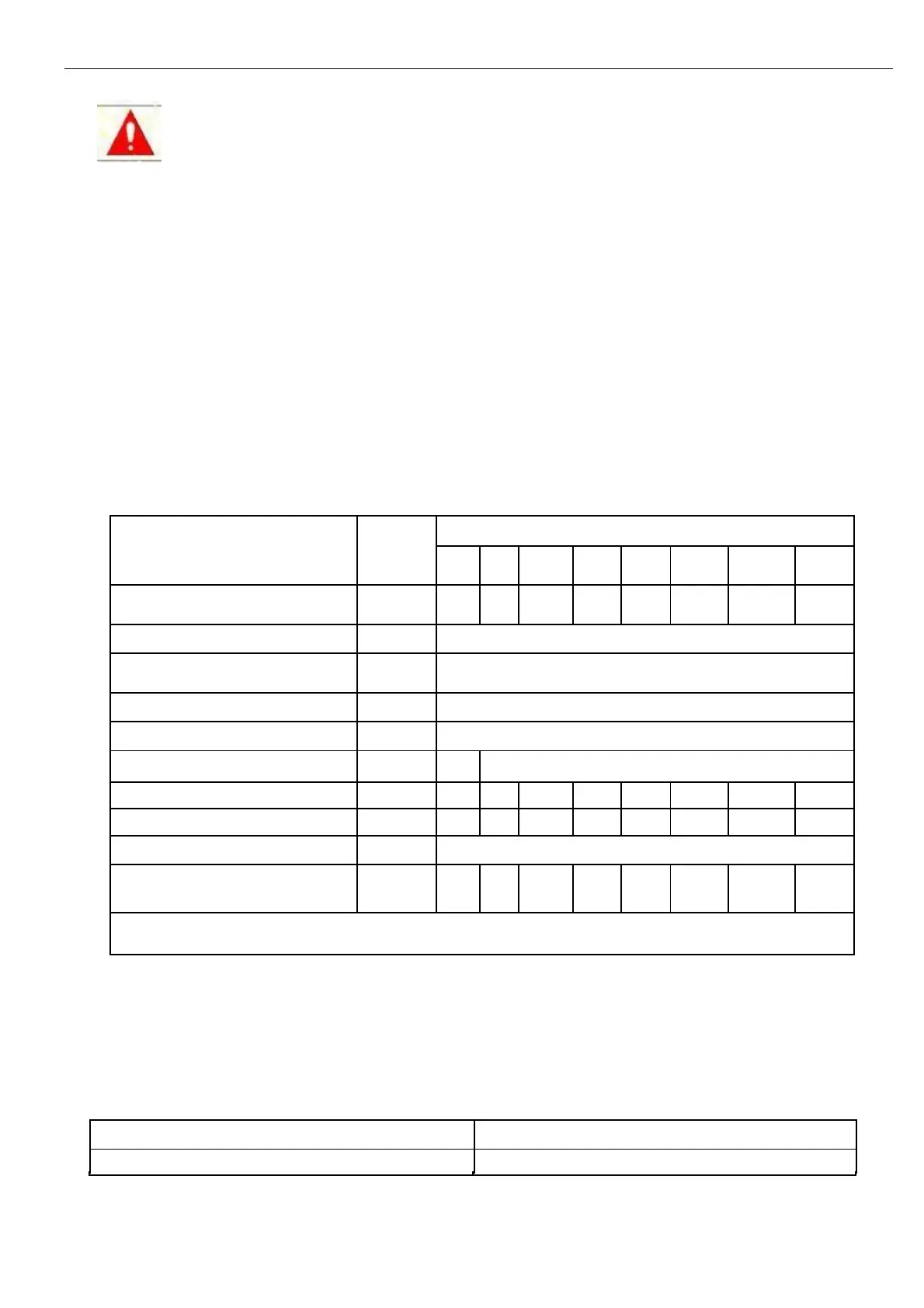

Others

Parts Quantity

Interval (h)

20 50 100 250 500 1000 2000 4000

Check if the bucket teeth is worn or

loosened

★

Change the bucket — If needed

Replace the bucket and connect the

new one to machine.

—

If needed, replace the bucket and connect the new one to

machine.

Adjust the connecting rod of bucket

1

If needed

Take down the traveling lever

2

If needed

Check and replace the fuse

1

★

Every 3 years

Check the track defection

2

★

Check tensioner

2

★

Check the fuel injection timing —

If needed

Check the bolts and nuts for

tightening torque

—

★

Note: ★Maintenance interval under normal conditions

Maintenance needed at the f irst inspection

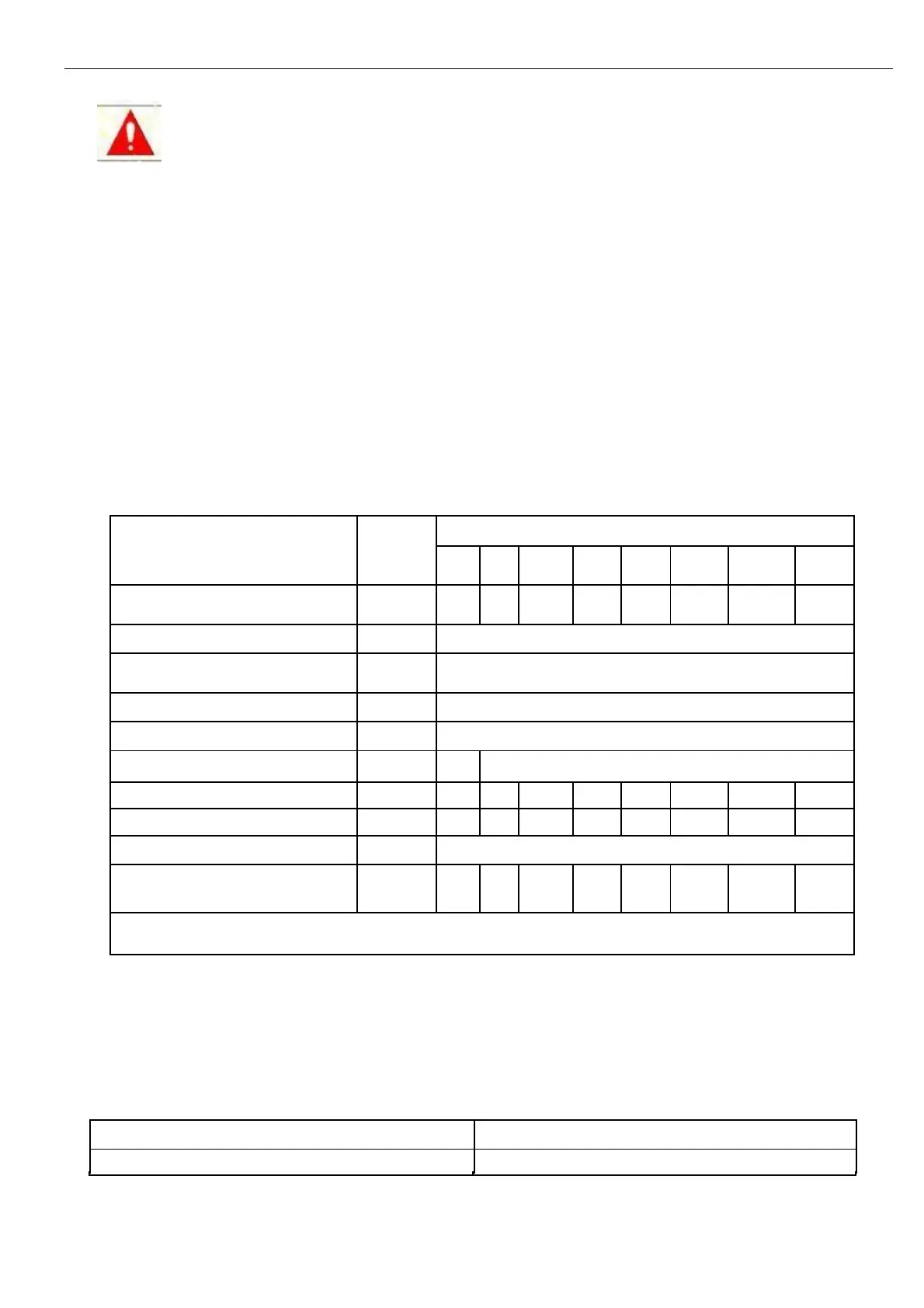

Check the bucket teeth --- each day

1. Check if the bucket teeth is worn or loosened.

Worn beyond the service limit, the bucket teeth may be replaced.

Bucket tooth dimensions mm

New Service limit

190 130

Loading...

Loading...