12

ENGLISH

Introduction

Thank you for purchasing one of our

products. Before using the equipment

you should carefully read the instruc-

tions included in this manual. In order to

get the best performance from the sys-

tem and ensure that its parts last as long

as possible, you must strictly follow the

usage instructions and the maintenance

regulations included in this manual. In

the interest of customers, you are rec-

ommended to have maintenance and,

where necessary, repairs carried out by

the workshops of our service organisa-

tion, since they have suitable equipment

and specially trained personnel availa-

ble. All our machinery and systems are

subject to continual development. We

must therefore reserve the right to mod-

ify their construction and properties.

Description

MATRIX 250 HF

high-frequency striking

TIG

generator - which is the result of the

ultimate

IGBT

- based inverter technol-

ogy - is equipped with a complete and

new digital control on all welding param-

eters.

MATRIX 250 HF

is a technologically ulti-

mate, strong and easy-to-use generator;

when used in direct current, it allows

TIG

welding of stainless steel, carbon steel,

copper and its alloys, also ensuring ideal

performance in

MMA

weld, with any

type of electrode.

FEATURES

• Digital control of all the welding

parameters.

• Standard equipped with pulse mode

integrated into the control with availa-

ble "EASY PULSE" facility.

• Excellent TIG welding characteristics.

• High frequency Arc Striking, precise

and efficient even from long distance.

• "Energy Saving" function to operate

the power source cooling fan and the

torch water cooling only when neces-

sary.

• Automatic compensation for mains

voltage fluctuations within +15% -

20%.

• Very good MMA welding characteris-

tics with any type of electrodes.

• Easy-to-use.

• Low energy consumption.

• Ability of storing and recalling person-

alised welding program.

• Electromagnetic disturbance reduc-

tion because of high frequency used

at arc striking only.

• Using special TIG torches allows

remote adjustment of welding current

directly from the torch.

• Overheating thermostatic protection.

• Compact and innovative design.

• Metallic main structure with shock-

proof plastic front panel.

• Control panel protected against acci-

dental impact.

• Robust handle integrated into the

chassis.

• Sloping front panel easy to read and

adjust and highly visible from any

direction.

• Reduced weight and size, easy-to-

carry.

• IP 23 protection class and dust proof

electronic components, thanks to the

Introduction 12

Description 12

Technical data 13

Usage limits (ISO IEC 60974-1) 13

Safety standards 13

Installation 14

Connection to the

electrical supply 14

Usage norms 14

Connection of the

welding cables 15

Weld parameters 16

Maintenance 20

Error signals 20

The pointing out of any

difficulties and their elimination 21

Procedure for cover assembly

and disassembly 21

Procedure for welder assembly

and disassembly 21

Adjustment of electronic

circuit board 93

Wiring diagram 94

Key to the electrical diagram 95

Colour key 95

Meaning of graphic symbols on

machine 100

Meaning of graphic symboles on

rating plate 101

Spare parts list 102-104

Ordering spare parts 106

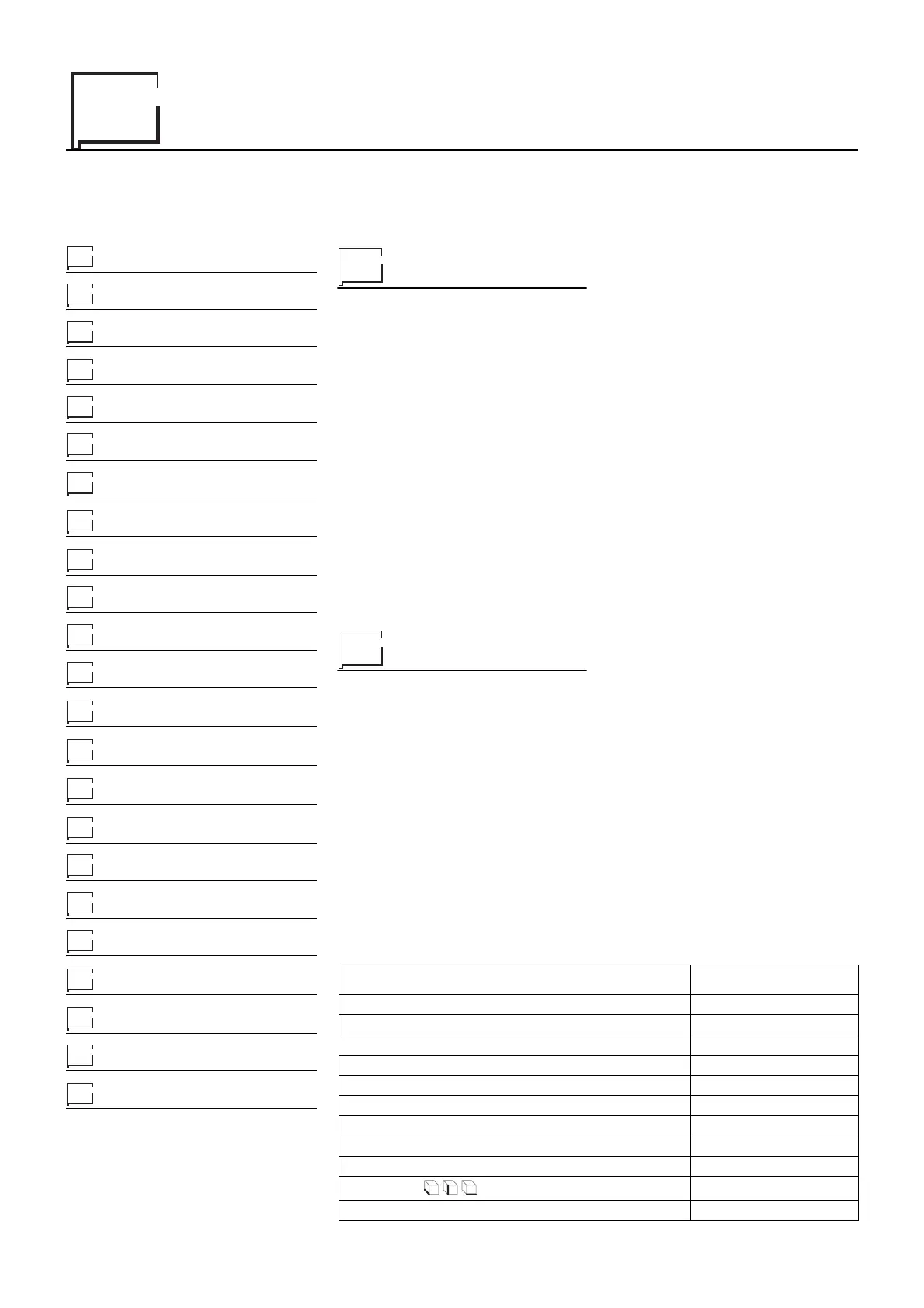

Table 1

Model MATRIX 250 HF

Three phase feeding 50/60 Hz V 400

Adjustment field A 5 ÷ 250

Maximum potential kVA 7

Secondary idle voltage V 95

100% usable current A 170

60% usable current A 200

35% usable current A 250

Insulation class H

Protection class IP 23

Dimensions

mm 500-425-220

Weight kg 22

UK

Loading...

Loading...