page 35 www.centsys.com

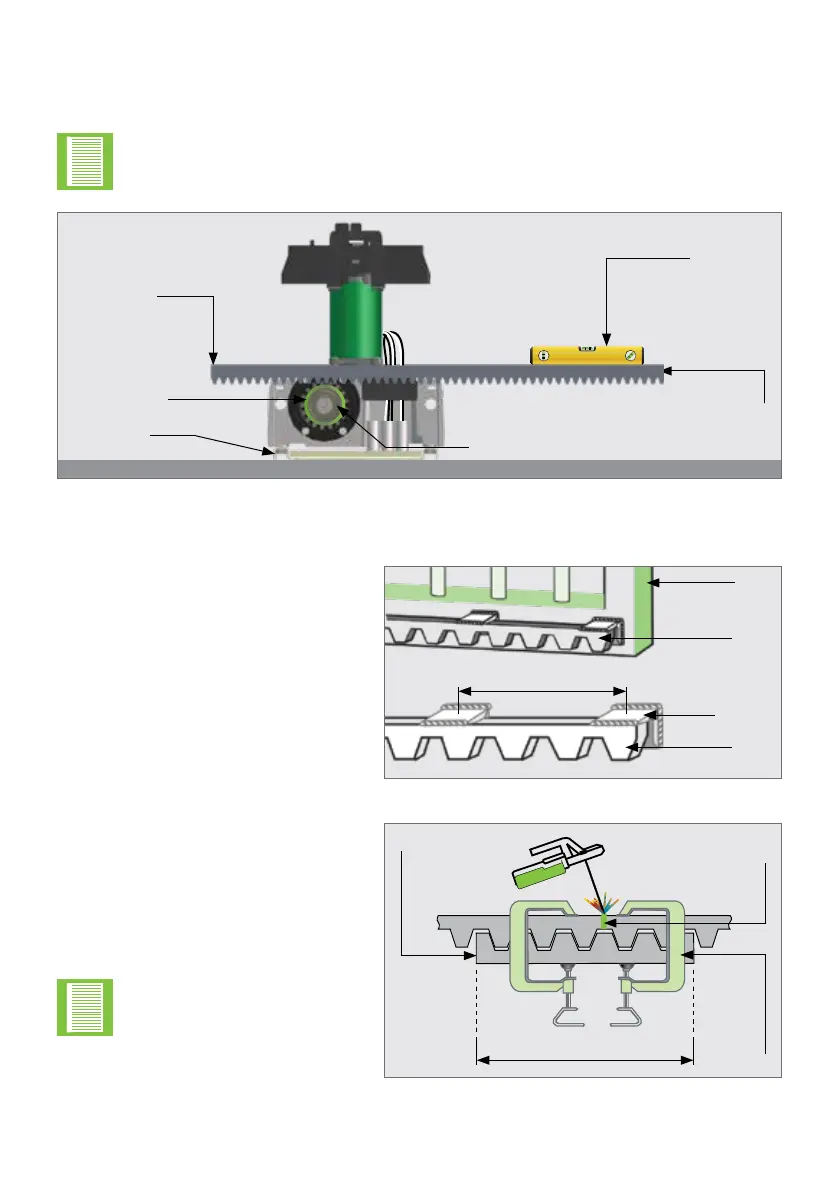

Pinion Spyder

First

Secured End

Spirit Level

Pinion

Foundation

Plate

FIGURE 46. THE RACK AND OPERATOR FROM THE GATE'S PERSPECTIVE

Slide the gate halfway along the rst section and level the unsecured end, ensuring that

the rack is resting on the Pinion Spyder, not pressing down. Continue this way to x all

sections.

Level this end of the rack,

and x it to the gate

Before fully xing each section of rack, slide the gate backwards and forwards

along the section, checking that the rack is only resting on the Pinion Spyder,

and not pressing down onto it.

OPERATOR INSTALLATIONSECTION 7

7.9.1. Fitting Steel Rack to the Gate

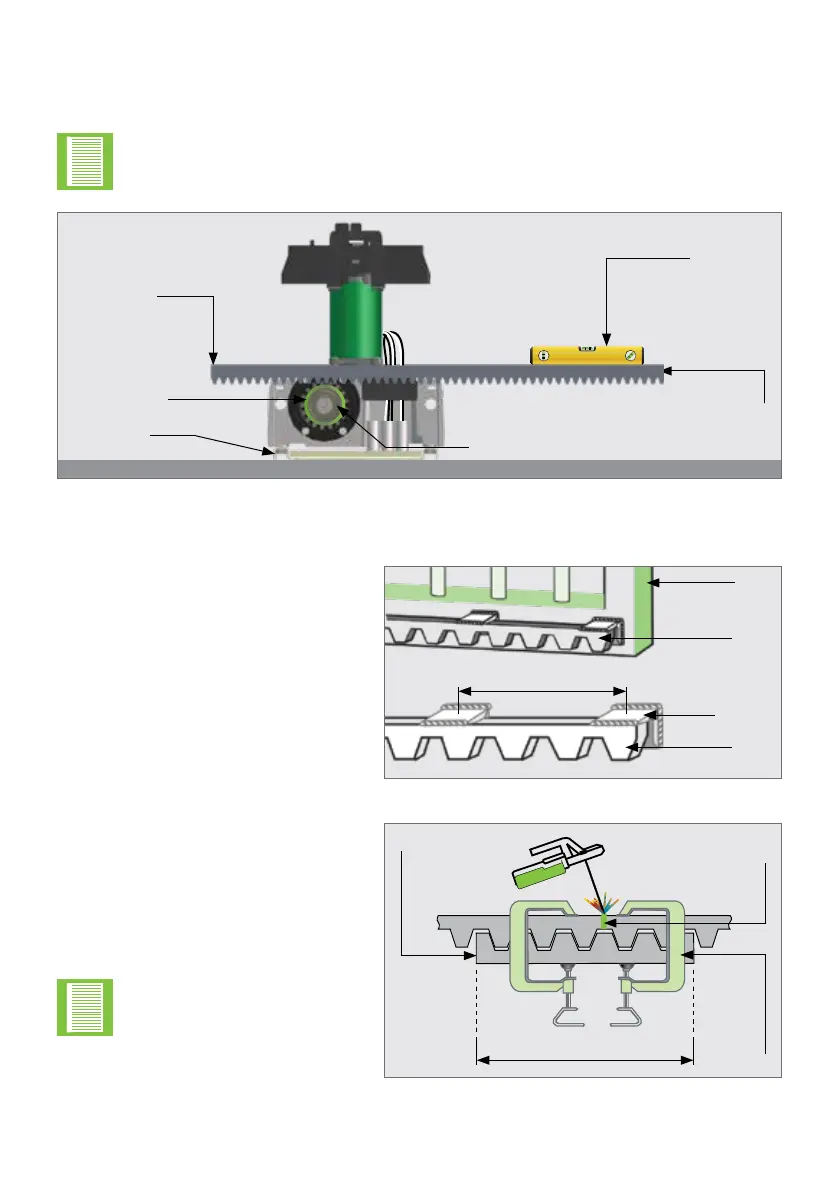

FIGURE 47

FIGURE 48

±300mm

Gate

Steel

Rack

Welded

join

Clamp

O-cut

Steel

Bracket

Steel

Rack

Fix the Steel Rack with the steel

angle brackets

1

. The brackets must

be spaced no more than 300mm

apart.

When joining dierent lengths of

Steel Rack, a simple way of ensuring

that the correct pitch spacing is

achieved, is to clamp a small o-cut

between the two pieces.

Do not weld the o-cut

to the gate or the join.

±300mm

1. The Steel Angle Brackets are not supplied with the D10 SMART / D10 Turbo SMART / D20 SMART.

Loading...

Loading...