page 51 www.centsys.com

GENERAL MAINTENANCESECTION 9

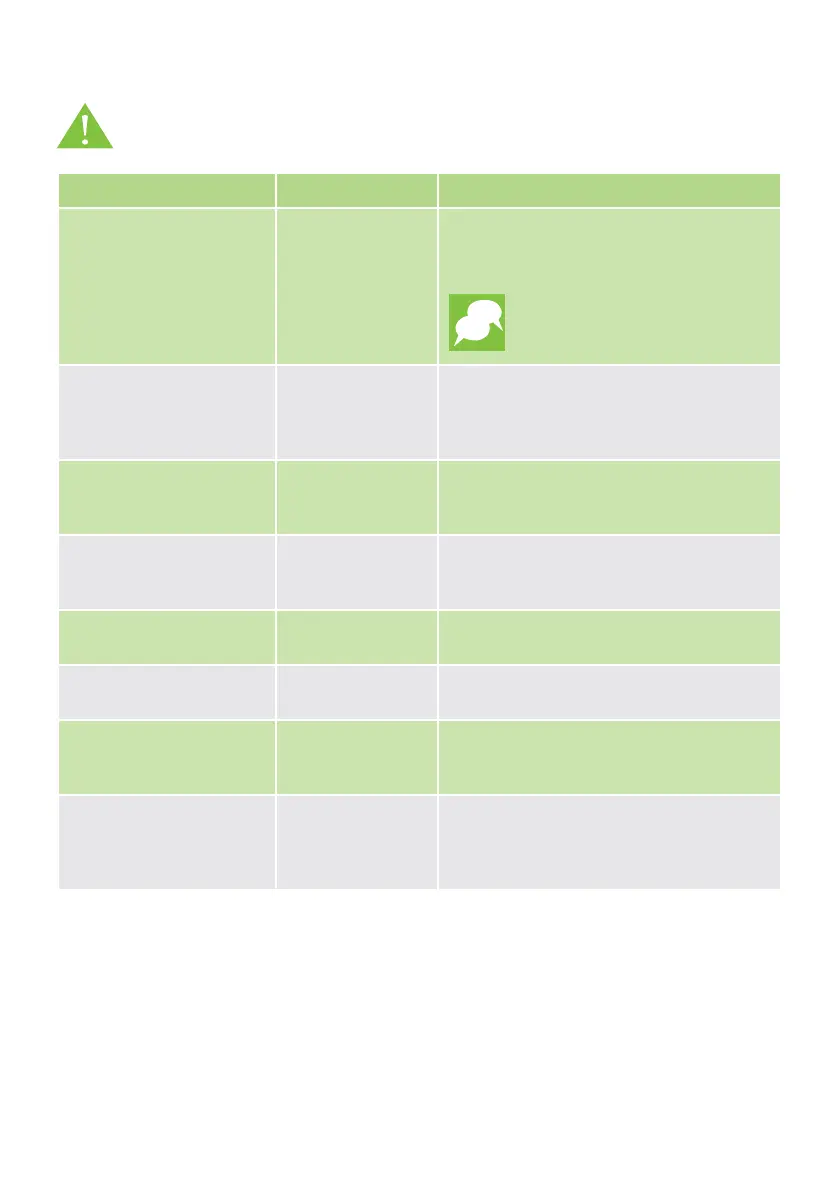

TABLE 5

9.2. D10 SMART / D10 Turbo SMART / D20 SMART Maintenance

Description Frequency Corrective Action

Check for insect

infestations

Every 3 months

Clean and remove any nests that are

settling in and around the motor and

Control Card

Check that the

mounting nuts are tight

on the foundation plate

bolts

Every 6 months Torque setting 20Nm

Check that there is no

sand build-up inside the

unit

Every 6 months

Remove batteries and lower battery

tray and clear out the sand build-up

Check pinion and rack

engagement

Every 6 months

If the mesh is too loose or the rack is

riding on the pinion, contact an installer

to correct

Check the condition of

the pinion

Every 6 months

If the pinion is excessively worn,

contact an installer to replace

Check the condition of

the override camlock

Every 6 months Dry lubricate if necessary (graphite)

If used, check the

condition of the theft-

deterrent cage

Every 6 months

Ensure that the device is serving its

purpose

If used, check the

condition of the theft-

deterrent cage lock and

that it operates

Every 6 months Dry lubricate if necessary (graphite)

Before performing any maintenance, ensure that the D10 SMART /

D10 Turbo SMART / D20 SMART is isolated or is disconnected from

the mains supply!

Insert a moth ball, which may

help to repel insects, at the

bottom of the gearbox

Loading...

Loading...