page 20 www.centsys.com

OPERATOR INSTALLATIONSECTION 7

D10 SMART - Steel Rack

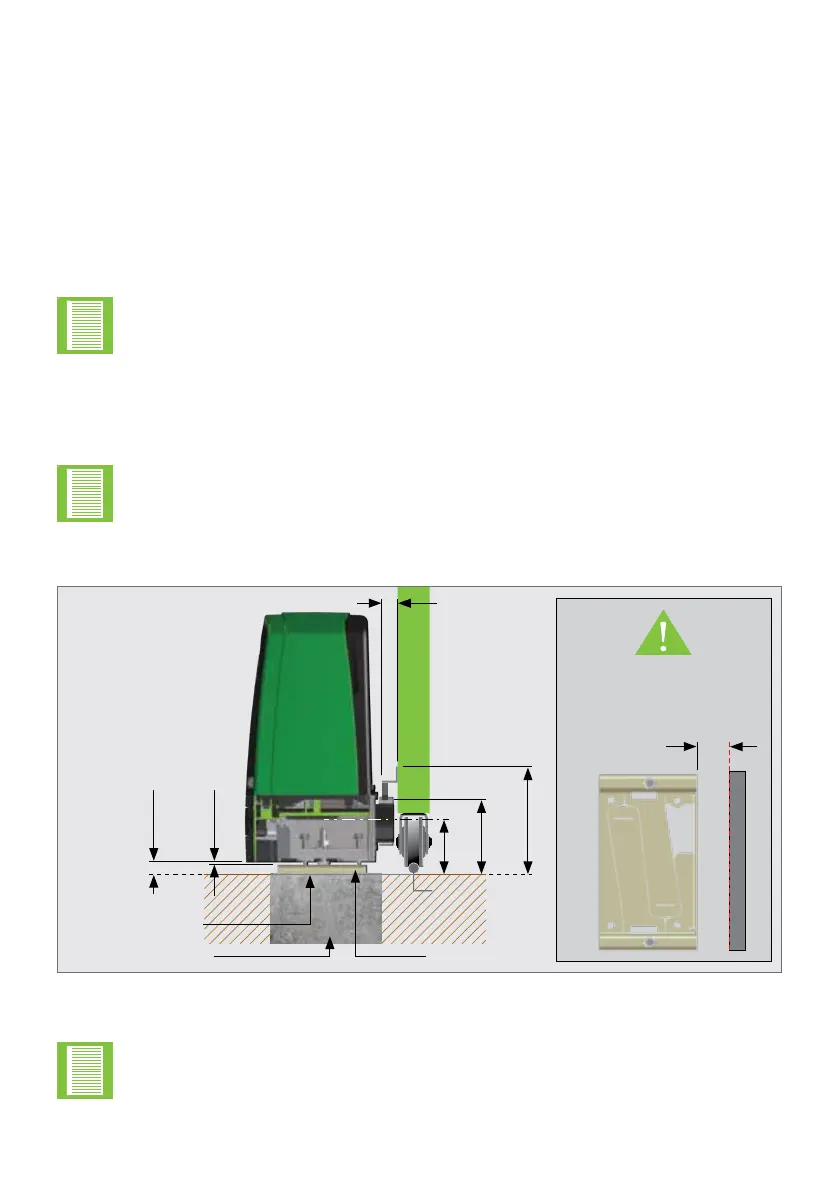

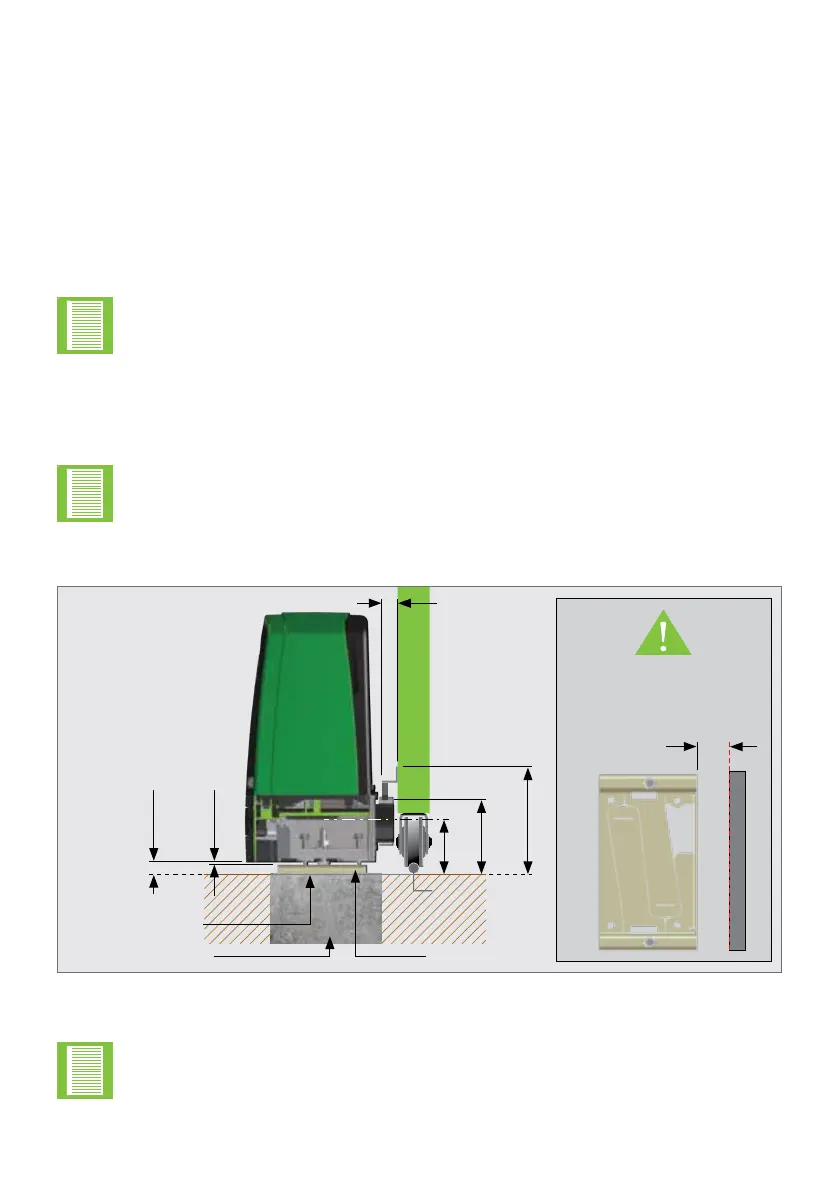

FIGURE 11. STEEL RACK ABOVE PINION

1. Includes 3mm clearance required between rack and pinion

2. Distance between bottom of the Foundation Plate and bottom edge of the Rack Tooth

If there is space to mount the rack underneath without fouling the ground as the

gate moves, the following are the pros and cons:

Pros

• The rack is more hidden from view

• It provides a very eective anti-lift bracket

• It ensures that, since the gate beds in, the rack does not drop onto the

pinion, loading the operator unnecessarily

Cons

• Rack teeth face up vertically, potentially collecting dirt

• Could require the use of a custom bracket

To ensure that the operator does not protrude into the driveway, install the base plate at

least ush with the driveway entrance.

It is typical to mount the rack above the pinion as shown in Figures 11, 13 and 15.

However, Figures 12, 14 and 16 shows the rack mounted underneath.

7.1.3. Locating the Operator's Position

The measurements given below are based on the rack supplied by

Centurion Systems (Pty) Ltd and are to be used as guidelines only.

5mm

25mm

91mm

121mm

1,2

176mm

1

25mm

(Typical Steel

Rack Width)

Flat bar welded

to Foundation Plate

and rail

Concrete Foundation

(Recommended to allow

for adjustment)

Minimum space from edge

of Foundation Plate to

reference point of edge that

protrudes the furthest.

(Section 7.1.1.)

Foundation Plate

50mm

The principles of installation on a Steel Rack is to position it in the middle of the

output pinion with the operator fully forward on the slots.

Loading...

Loading...