50

Troubleshooting (continued)

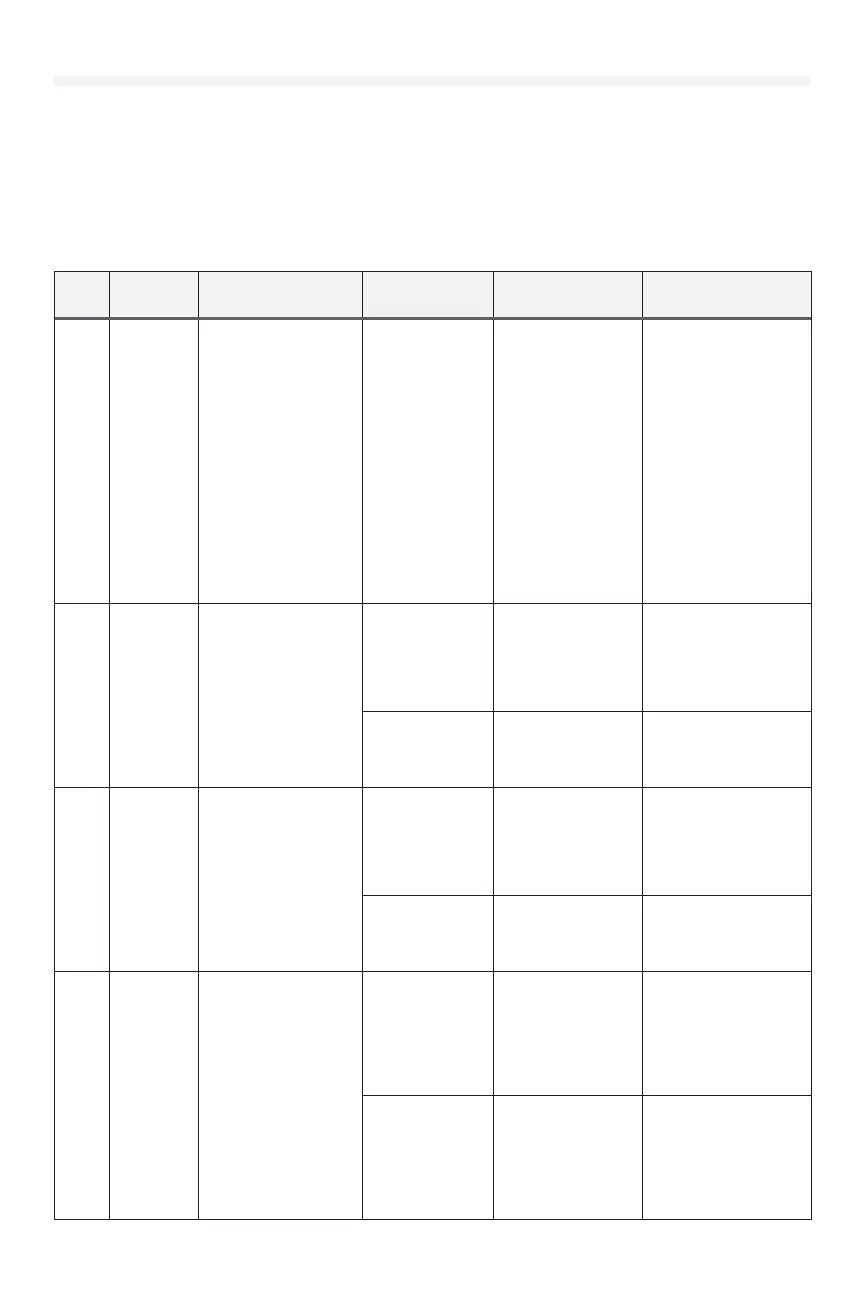

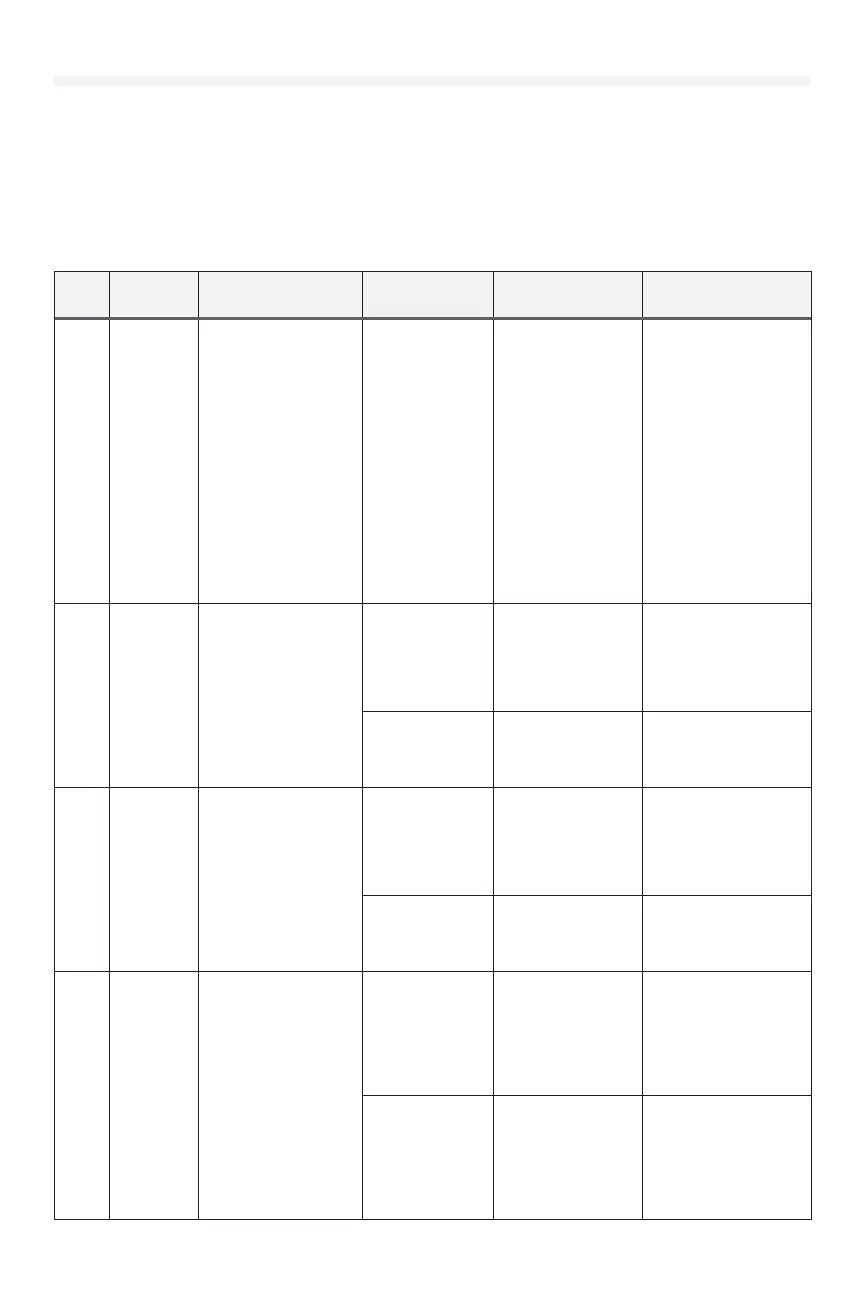

If an error occurs, the idle screen is replaced by a screen showing the error code and a description of the error.

Error messages originate in one of three categories:

• Motor drive and power circuitry

• Door control codes related to the motor and encoder

• Option codes related to accessories used with the industrial DC operator.

Consult the Table of Error Codes below to determine the cause and corrective action. Depending on the type of error,

user interaction may be required to clear the error. The error window closes when the error has been cleared/corrected.

Code

Display

Message

Description Possible Causes Diagnosis Resolution

MOVE THE

DOOR

Displayed in limit learn

mode.

The position encoder

requires some

movement before

the position can be

determined on powerup.

Once the position has

been successfully

determined, the

position will be

maintained until power

is lost.

Door has not been

moved since the

last power cycle

Upon initial powerup,

this message will

be displayed in the

limit learn menu if no

other movement has

occurred.

Move the door slightly in

either direction using the

up or down buttons on

the wall control. 'MOVE

THE DOOR' message will

disappear.

If door does not move,

or moves and stops, see

troubleshooting steps

for F04 UNAUTHORIZED

STOP.

If door moves without

issue but 'MOVE

THE DOOR' stays

on the screen, see

troubleshooting steps

for F91 ENCODER.

F01 F01 CLOSE

LIMIT

Door has moved

beyond the lower end

position

Operator has

been manually

hoisted below the

lower end position

(hoisted jackshaft

models only)

Check position of

door/operator with

manual hoist

Move position back

within normal limits.

Adjust door position

limits if necessary.

Door is falling or

drifting downward

when operator is

stopped

Check for excessive

door imbalance in

down direction

Rebalance door

replace broken springs

ensure correct springs

and drums are used

F02 F02 OPEN

LIMIT

Door has moved

beyond the upper end

position

Operator has been

manually hoisted

above the upper

position limit

(hoisted jackshaft

models only)

Check position of

door/operator with

manual hoist

Move position back

within normal limits.

Adjust door position

limits if necessary.

Door is drifting

upward when

operator is

stopped

Check for excessive

door imbalance in up

direction

Rebalance door

Ensure correct springs

and drums are used

F04 F04

UNAUTH.

STOP

(continued)

No motor motion

was detected when

the operator was

attempting to move the

motor.

Door encountered

obstruction or

other mechanical

jam

Check doorway

for obstruction.

Check to ensure the

mechanical system

moves properly and

without hangups or

excessive resistance.

Remove obstruction

Motor cable is

disconnected or

wiring fault

Check that motor

cable is plugged into

the powerhead main

board completely.

Ensure that motor

cable is intact and in

good condition.

Ensure motor connector

is fully seated.

Repair any problems

with the cabling.

If cabling is beyond

repair, replace motor.

Loading...

Loading...