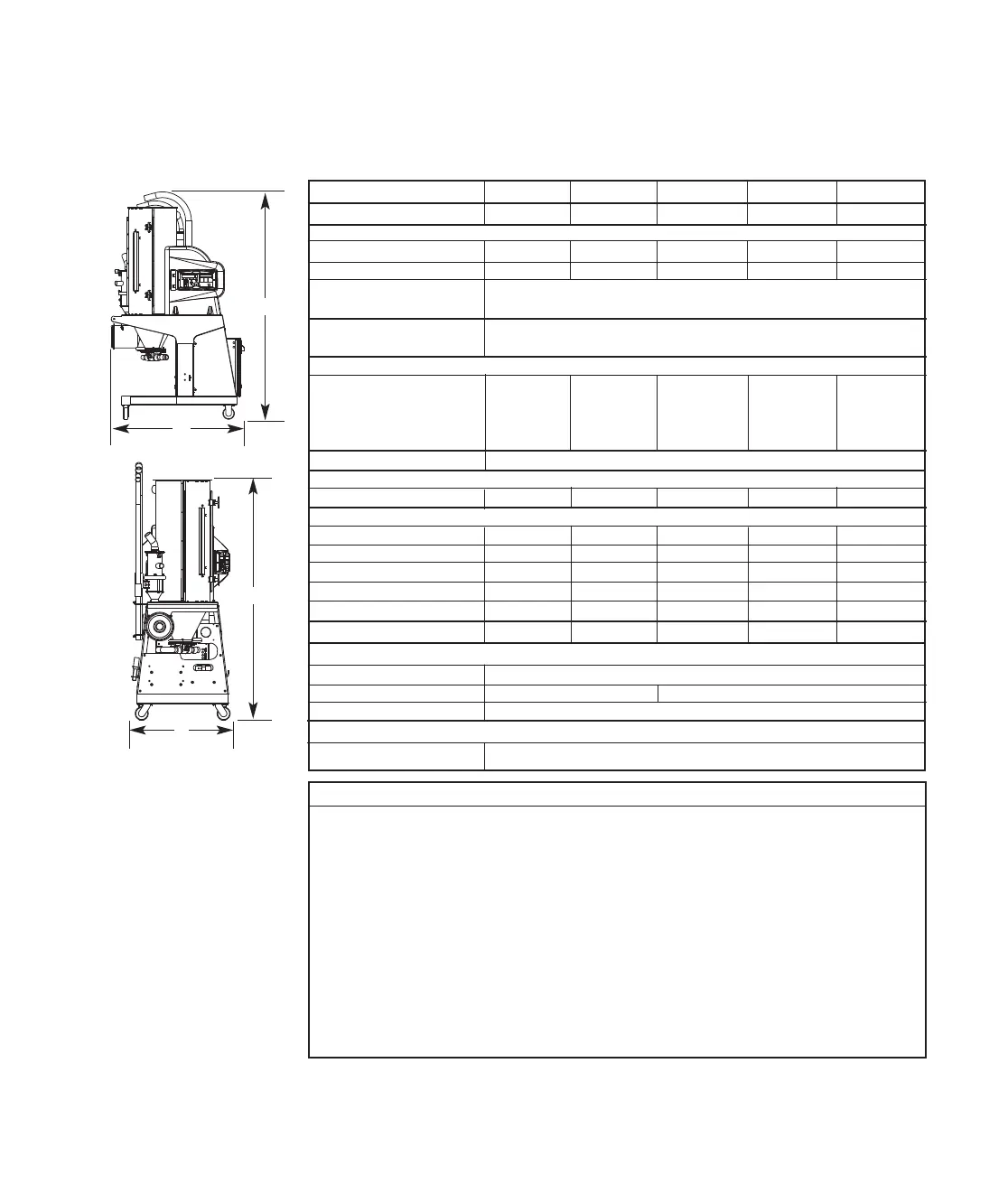

B

A

D

Specifications: MDCW Carousel

Plus Dryers

MODEL W15 W25 W50 W75 W100

Standard hopper models* RWH14-2 RWH14-3 RWH18-6 RWH24-9 RWH24-12

Performance characteristics (with full hopper)

Air flow {SCFM}

**

7.5 12.5 25 37.5 50

Air flow {ACFM @ 250

°F

}

**

10 17 34 50 67

Drying temperature All models 150 - 375

°

F {66 - 191

°

C} with options

Dew point All models -40

°

F {-40

°

C}

Standard conveying dist. ft {m} 8 {2.44} vertical; 6 {1.83} horizontal

Long distance option ft {m} 15 {4.57} vertical; 50 {15.24} horizontal

Dimensions inches {cm}

A - Height top of convey pipe 78.5 {199.4} 78.5 {199.4} 87.5 {222.3} 87.5 {222.3} 87.5 {222.3}

B - Overall width 28.5 {72.4} 28.5 {72.4} 40.5 {102.9} 40.5 {102.9} 40.5 {102.9}

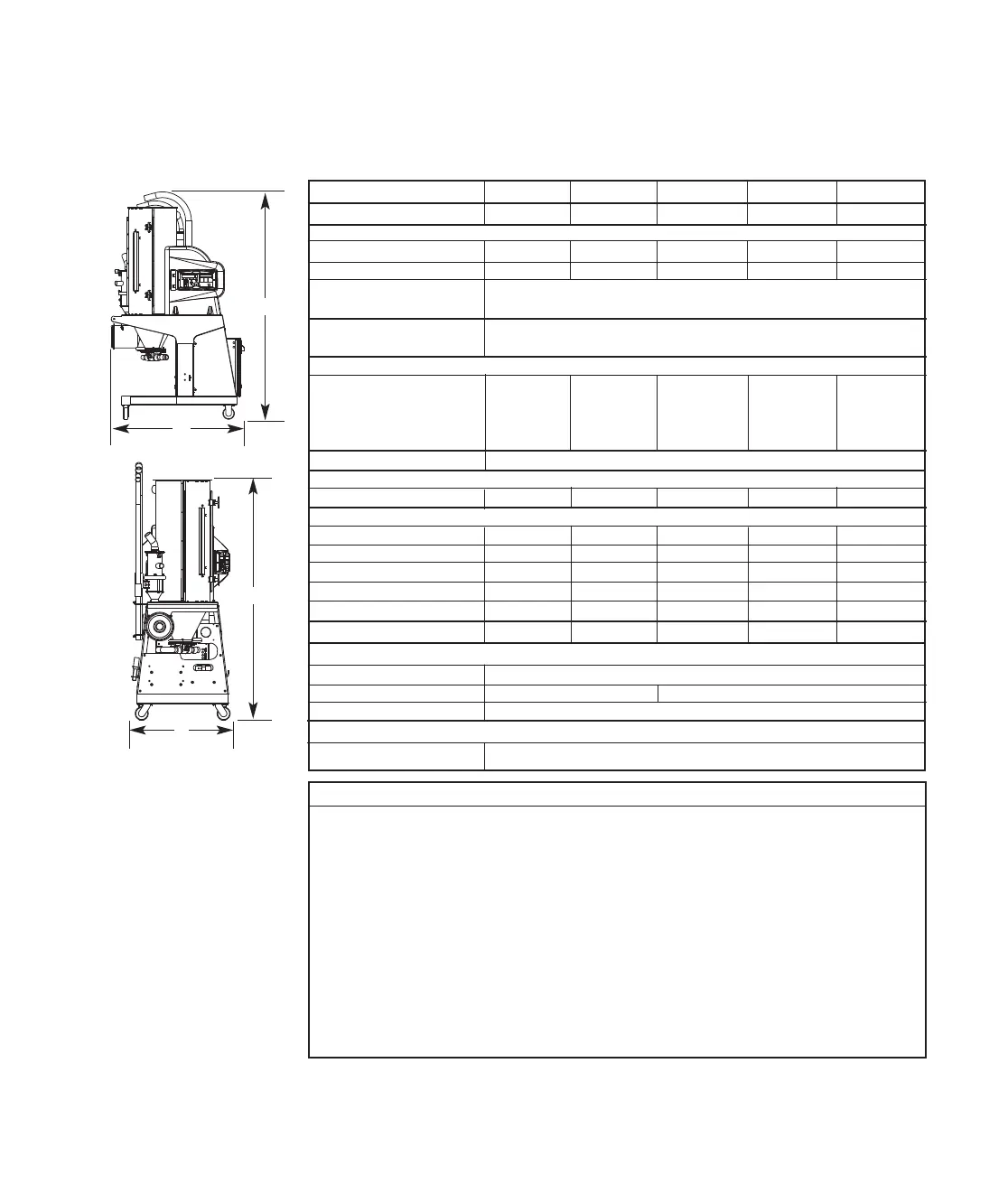

C - Height to top of hopper 60.5 {153.7} 73.5 {186.7} 90.5 {229.9} 82.5 {209.6} 93.5 {237.5}

D - Depth 46 {116.8} 46 {116.8} 58 {147.3} 58 {147.3} 58 {147.3}

Outlet/inlet tube OD in. {cm} 2.5 {6.35}

Weight lbs {kg}

Standard dryer installed 500 {226.8} 550 {249.5} 600 {272.2} 675 {306.2} 750 340.2}

Voltage - Total Amps {standard/long conveying distance}

208 V/3 phase/60 Hz 16.9/20.9 16.9/20.9 21.9/25.9 22.8/26.8 NA

230 V/3 phase/60 Hz 15.3/18.9 15.3/18.9 19.8/23.4 20.6/24.2 24.9/30.5

400 V/3 phase/50 Hz ‡ 8.5/9.6 8.5/9.6 11/12.1 11.5/12.6 15.1/16.2

460 V/3 phase/60 Hz 7.7/9.5 7.7/9.5 9.9/11.7 10.3/12.1 13.4/15.2

575 V/3 phase/60 Hz 6.0/7.8 6.0/7.8 7.8/9.4 8.2/9.8 10.7/12.5

Total kilowatts † kw {std./long} 1.5/2.7 1.5/2.7 1.9/3.0 4.0/5.1 4.6/5.7

Water requirements {for optional aftercooler}

Recommended temp. § 45

°

- 85

°

F {7.2 - 29.4

°

C}

Water flow gal/min {liters/min} 1 {4.6} 2 {9.1}

Water connections NPT 3/4 in. NPT

Compressed air requirements {self-loading option only}

Compressed air 0.5 SCFH @ 80 psi

SPECIFICATION NOTES:

* Other hopper sizes are available.

** The term

SCFM stands for Standard Cubic Feet Per Minute, referenced to a pre-specified pressure, temperature and relative

humidity. In most cases, SCFM is referenced to 14.7 PSIA 68° F and 36% relative humidity. ACFM stands for Actual Cubic Feet

Per Minute, and must be supplied with a temperature reference, due to the change in air density with temperature. Because dry-

ers operate at a relatively low pressure the effects on air density are negligible.

‡ Dryers running at 50 HZ will have 17% less airflow, and a 17% reduction in material throughput.

† TOTAL kW listed at a process setpoint of 250°F {121.1°C} and a regeneration temperature of 350°F {176.7°C}.

§

Temperatures above or below the recommended levels may affect dryer performance. Tower, chiller, or municipal water

sources can be used.

Specifications may change without notice. Consult a Conair representative for the most current information.

C

(continued)

2-8 l Des cri pt io n

TPDS020-0311-REV

Loading...

Loading...