Checking for Proper Air Flow

IMPORTANT: This procedure is needed on non-conveying MDCW models 50, 75, and

100. This procedure is not required on the conveying MDCW 15 - 100 models because

phase detection is standard.

CAUTION: Checking for proper air flow must be performed before filling the hopper

with material. Performing this step after the hopper is filled with material could

cause damage to the dryer if the airflow direction is incorrect due to improper

phase connection. Material from the hopper can be pulled into the process heater,

causing permanent damage.

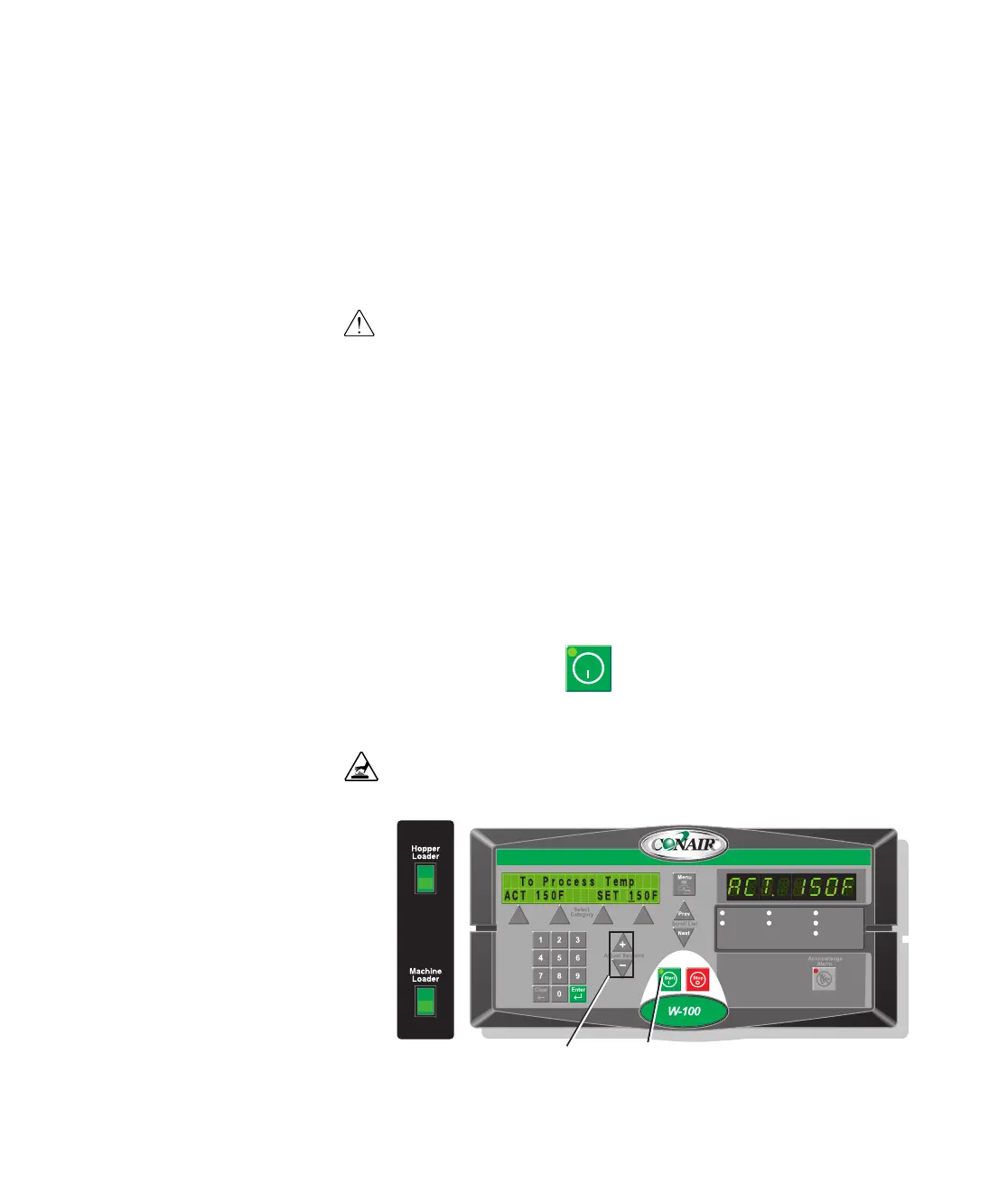

1 Turn on the main power to the dryer. Make sure the dryer's disconnect dial is

in the ON position. This powers up the control and the display lights will illu-

minate.

2 Set the drying temperature. Press the select category button under the set-

point value until it blinks then use setpoint adjust (+) or (-) buttons or enter the

low setpoint temperature (150ºF {66ºC}) on the numeric keypad and press

enter.

3 Press the START button. Disconnect the process filter and feel for

suction at the inlet to the filter. If the airflow is traveling in the correct direction

you should feel suction.

Auto Start

Dewpoint Control

Set-Back Temp.

Process Blower

Process Heater

Regen. Blower

Regen. Heater

Setpoint Adjust

Buttons

(continued)

3-12 l In sta ll ation

Start Button

CAUTION: Hot surface. Do not place your hand directly on the delivery air outlet.

The outlet and the air can get hot enough to burn your hand.

Loading...

Loading...