26

4.1.1

EN

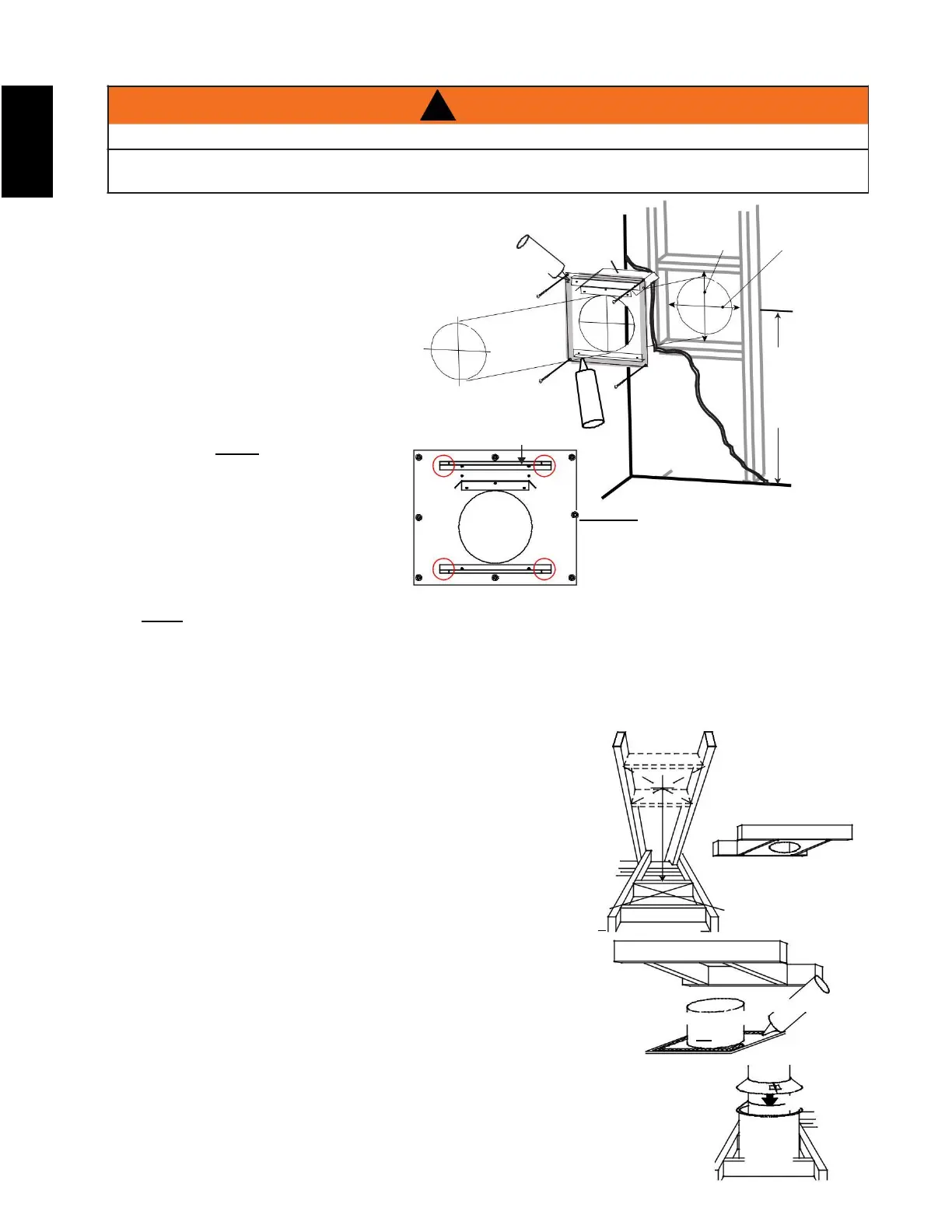

horizontal installation

! WARNING

THE FIRESTOP ASSEMBLY MUST BE INSTALLED WITH THE VENT SHIELD TO THE TOP.

TERMINALS MUST NOT BE RECESSED INTO A WALL OR SIDING MORE THAN THE DEPTH OF THE

RETURN FLANGE OF THE MOUNTING PLATE.

This application occurs when venting through

an exterior wall. Having determined the

correct height for the air terminal location, cut

and frame a hole in the exterior wall

as illustrated to accommodate the fi restop

assembly. Dry fi t the fi restop assembly

before proceeding to ensure the brackets on

the rear surface fi t to the inside surface of

the horizontal framing.

The vent shield must be installed to the full

depth of the combustible wall. The length

of the vent shield may be cut shorter for

combustible walls that are less than 8 1/2"

(216mm) thick. NOTE: Bend the tabs for

reduced side clearances or move the shield

for reduced top clearances.

A. Apply a bead of caulking (not supplied)

around the corner edge of the inside

surface of the fi restop assembly, fi t

the fi restop assembly to the hole and

secure using the 4 screws (supplied in

your manual baggie).

NOTE: The above is for illustration

purposes only. Vents do not

always pass through center of

frame.

NOTE : Do not fill the air space between the firestop spacer and the exterior wall with any type of

insulating material (i.e., spray foam).

B. Once the vent pipe is installed in

its fi nal position, apply red RTV silicone sealant (W573-0002) (not supplied) between the pipe and

the fi restop.

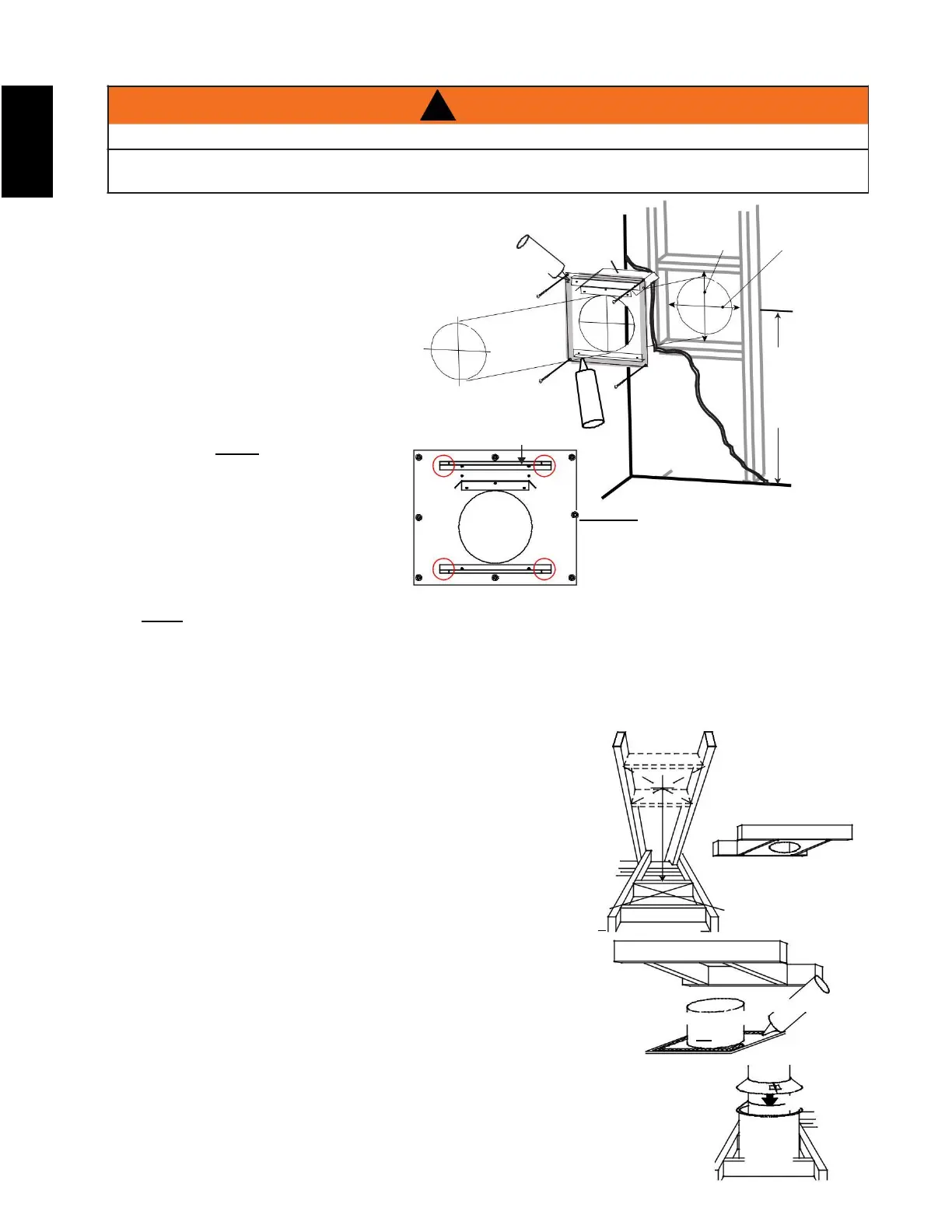

4.1.2 vertical installation

This application occurs when venting through a roof. Installation kits

for various roof pitches are available from your authorized dealer /

distributor. See accessories to order specific kits required.

A. Determine the air terminal location, cut and frame a square opening

as illustrated in the ceiling and the roof to provide the minimum 1"

(25mm) clearance between the vent pipe and any combustible

material. Try to center the vent pipe location midway between two

joists to prevent having to cut them. Use a plumb bob to line up the

center of the openings. A vent pipe shield will prevent any materials

such as insulation, from filling up the 1" (25mm) air space around the

pipe. Nail headers between the joist for extra support.

FIRESTOP

UNDERSIDE OF

JOIST

B. Apply a bead of caulking (not supplied) to the framework or to the

Wolf Steel vent pipe shield plate or equivalent (in the case of a finished

ceiling), and secure over the opening in the ceiling. A firestop must be placed

on the bottom of each framed opening in a roof or ceiling that the venting

system passes through. Apply a bead of caulking all around and place a

firestop spacer over the vent shield to restrict cold air from being drawn into the

room or around the fireplace. Ensure that both spacer and shield maintain the required

clearance to combustibles. Once the vent pipe is installed in its final position, apply

Mill Pac sealant (W573-0007) (not supplied) or red RTV silicone (W573-0002) (not

supplied) between the pipe and the firestop assembly.

In the attic, slide the vent pipe collar down to cover up the open end of the shield and

W415-1679 / D / 03.09.18

Loading...

Loading...