4.2.3 appliance vent connection

29

A. Install the inner exhaust fl ue collar to the appliance. Secure

with a minimum of 3 #8 screws. Seal the joint and screw holes

using Mill Pac sealant (W573-0007) (not supplied).

B. Install the outer fl ex pipe to the appliance. Attach and

seal the joints using a red RTV silicone and a minimum of

3 #8 screws.

4.3 using rigid vent components

#8 X 1/2”

SELF

DRILLING

SCREWS

EN

2” (50.8mm)

OVERLAP

HIGH TEMP

SEALANT

The vent system must be supported approximately every 3 feet (0.9m) for both vertical and horizontal runs.

Use Wolf Steel Ltd. support ring assembly or equivalent noncombustible strapping to maintain the minimum

clearance to combustibles for both vertical and horizontal runs.

All inner exhaust and outer intake vent pipe joints may be sealed using either red high temperature

silicone sealant (W573-0002) (not supplied) or black high temperature sealant W573-0007 Mill Pac (not

supplied) with the exception of the appliance exhaust flue collar which must be sealed using Mill Pac.

4.3.1 horizontal air terminal installation

! WARNING

RISK OF FIRE, DO NOT ALLOW LOOSE MATERIALS OR INSULATION TO TOUCH THE VENT

PIPE. REMOVE INSULATION TO ALLOW FOR THE INSTALLATION OF THE ATTIC SHIELD

AND TO MAINTAIN CLEARANCES TO COMBUSTIBLES.

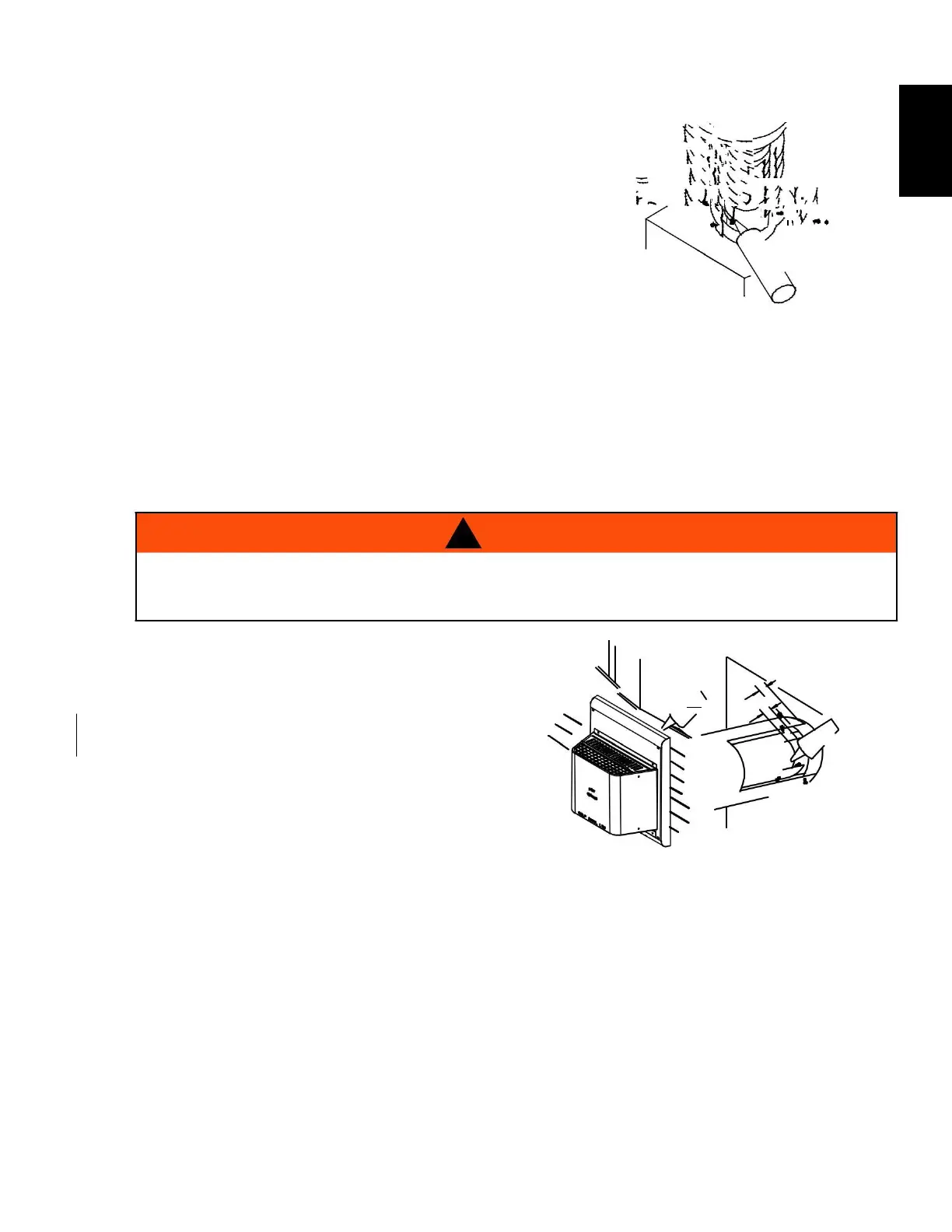

Move the appliance into position. Measure the

vent length required between terminal and

appliance taking into account the additional

length needed for the fi nished wall surface

and any 1” (25.4mm) overlaps between venting

Apply high temperature sealant W573-0007 Mill Pac

(not supplied) to the outer edge of the inner exhaust

fl ue collar of the appliance. Attach the fi rst inner

rigid pipe component and secure using a minimum of

3 self tapping screws. Repeat using the outer rigid pipe.

C. Insert the vent pipes through the fi restop maintaining the required clearance to combustibles. Holding

the air terminal (lettering in an upright, readable position), secure to the exterior wall and make

weather tight by sealing with caulking (not supplied).

The air terminal mounting plate may be recessed into the exterior wall or siding no greater than the

depth of the return flange.

W415-1679 / D / 03.09.18

Loading...

Loading...