53

10.1 pilot burner adjustment

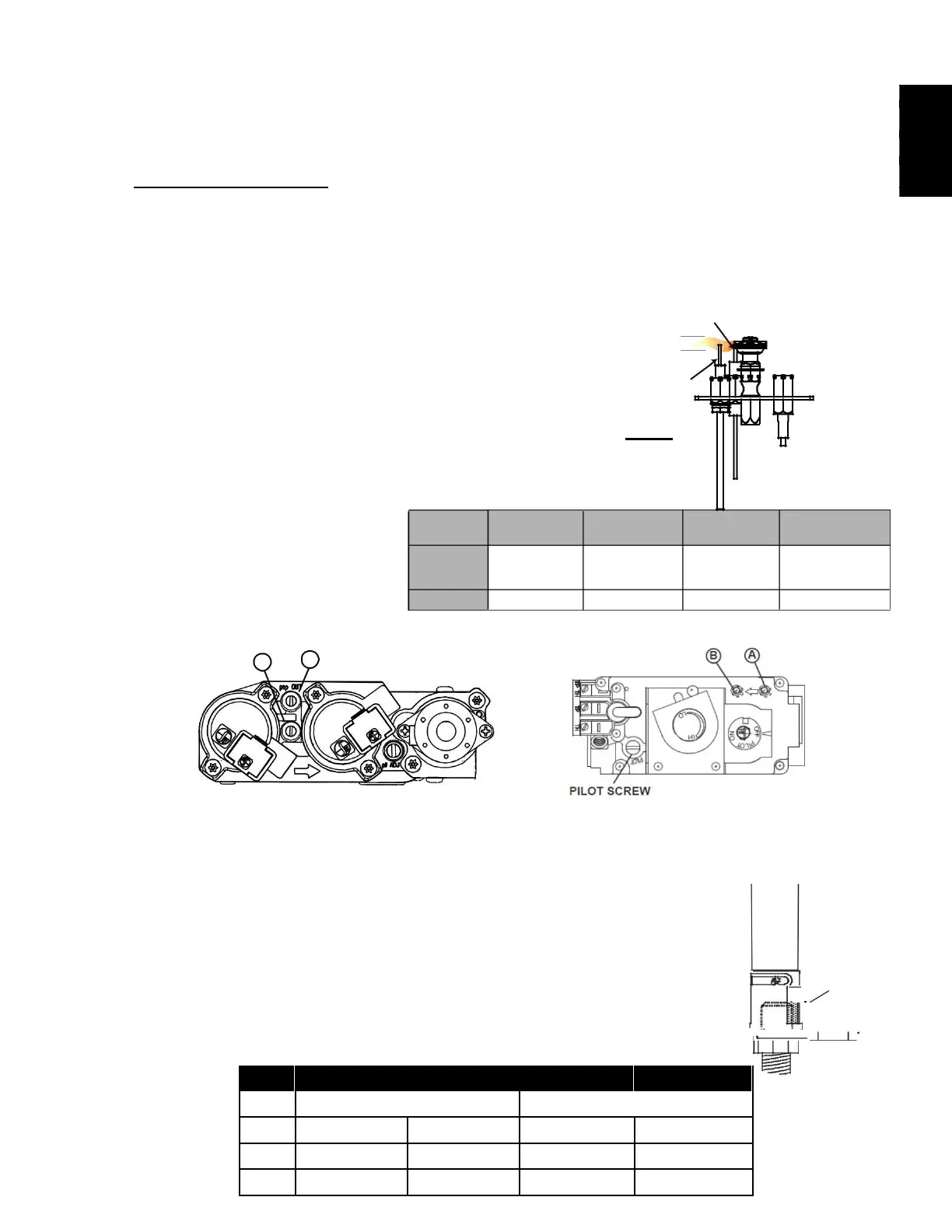

Adjust the pilow screw to provide properly sized flame. Turn in a clockwise direction to reduce the gas flow.

Inlet pressure can be checked

by turning screw A counter-clockwise 2 or 3 times, and then placing the pressure

gauge tubing over the test point. The gauge should read as described on the chart below. Check pressure with

the main burner operating on "HI".

Outlet pressure can be checked the same as above using screw B. The gauge should read as described on the

chart below. Check pressure with the main burner operating on "HI".

screw (B). Gauge should read as described on the chart

below. Check pressure with main burner operating on “HI”.

AFTER TAKING PRESSURE READINGS, BE SURE TO

AFTERTURNSCREWSTAKING PRESSURECLOCKWISEREADINGS,FIRMLYTOBERESEALSURETO.DO

TURNNOTOVERSCEWS-TORQUECLOCKWISE. FIRMLY TO RESEAL. DO

Leak test with a soap and water solution.

Leak test with a soap and water solution.

Prior to pilot adjustment, ensure that the pilot assembly

has not been painted. If overspray or painting of the pilot

UPPER 3/8” (9.5mm) TO 1/2”

assembly has occurred remove the paint from the pilot

assembly, or replace. Fine emery

cloth or a synthetic scrub pad (such as

Scotch-Brite™) can be used to remove

the paint from the pilot hood, electrode

*Maximum inlet pressure not to exceed 13”.

A B

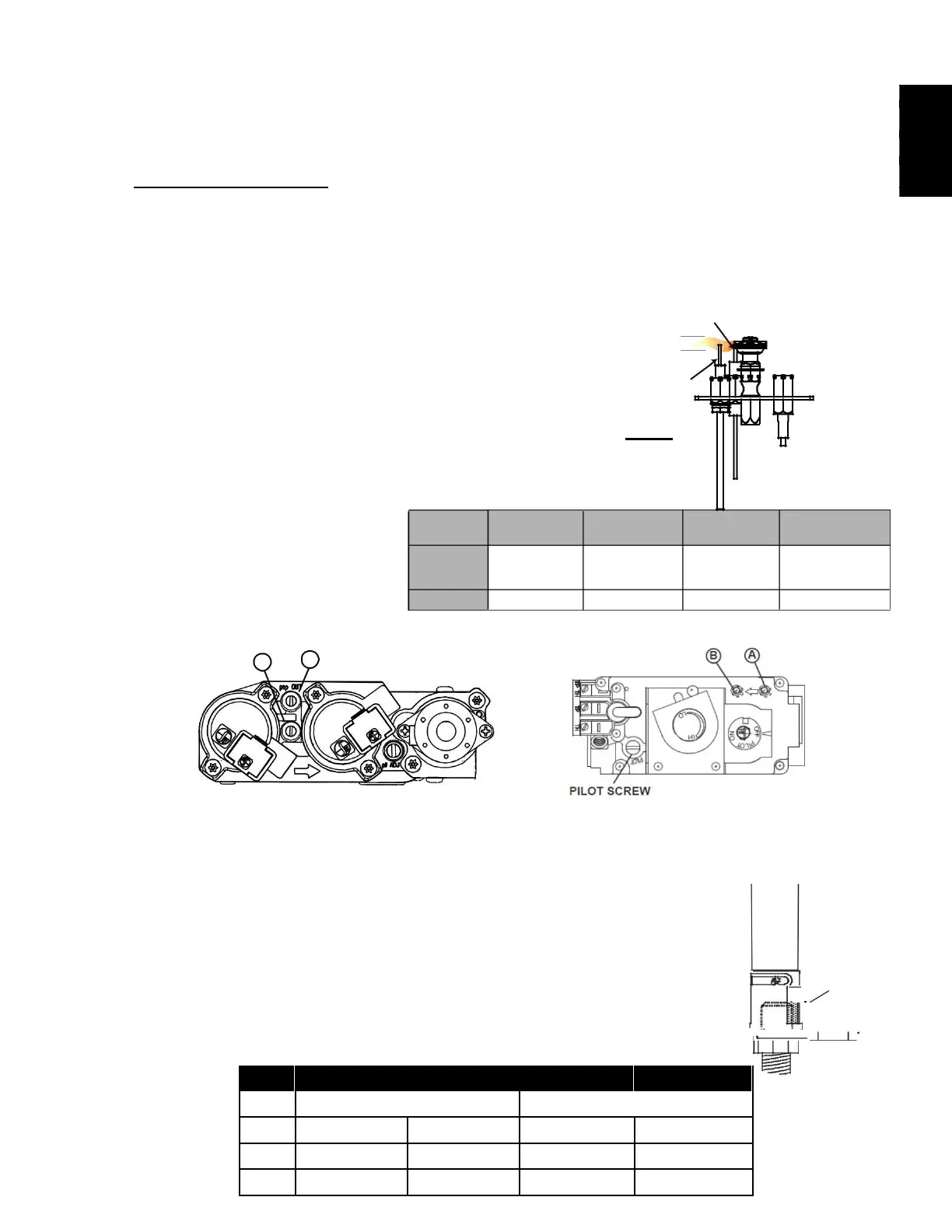

10.2 venturi adjustment

This appliance has an air shutter that has been factory set open according

to the chart below:

Regardless of venturi orientation, closing the air shutter will cause a more

yellow flame, but can lead to carbonization. Opening the air shutter will

cause a more blue flame, but can cause flame lifting from the burner ports.

The flame may not appear yellow immediately; allow 15 to 30 minutes for

the final flame colour to be established.

AIR SHUTTER ADJUSTMENT MUST ONLY BE DONE BY A QUALIFIED

VENTURI

BURNER

AIR

SHUTTER

OPENING

ORIFICE

W415-1679 / D / 03.09.18

Loading...

Loading...