70

EN

No spark at pilot burner.

No gas at the pilot burner.

Unit is over-fi red or underfi red.

*MAXIMUM INLET PRESSURE NOT TO EXCEED 13”

Carbon is being deposited

Air shutter has become blocked.

on glass, logs or combustion

Flame is impinging on the logs

Check if pilot can be lit by a match.

Check that the wire is connected to the push button igniter.

Check if the push button igniter needs tightening.

Replace the wire if the wire insulation is broken or frayed.

Replace the electrode if the ceramic insulator is cracked or broken.

Replace the push button ignitor

Spark gap should be 0.150” (3.8mm) to 0.175” (4.5mm) from the

electrode tip and the pilot burner. To ensure proper electrode

location, tighten securing nut (fi nger tight plus 1/4 turn).

Check that the manual valve is turned on.

Check the pilot orifi ce for blockage.

Call the gas distributor.

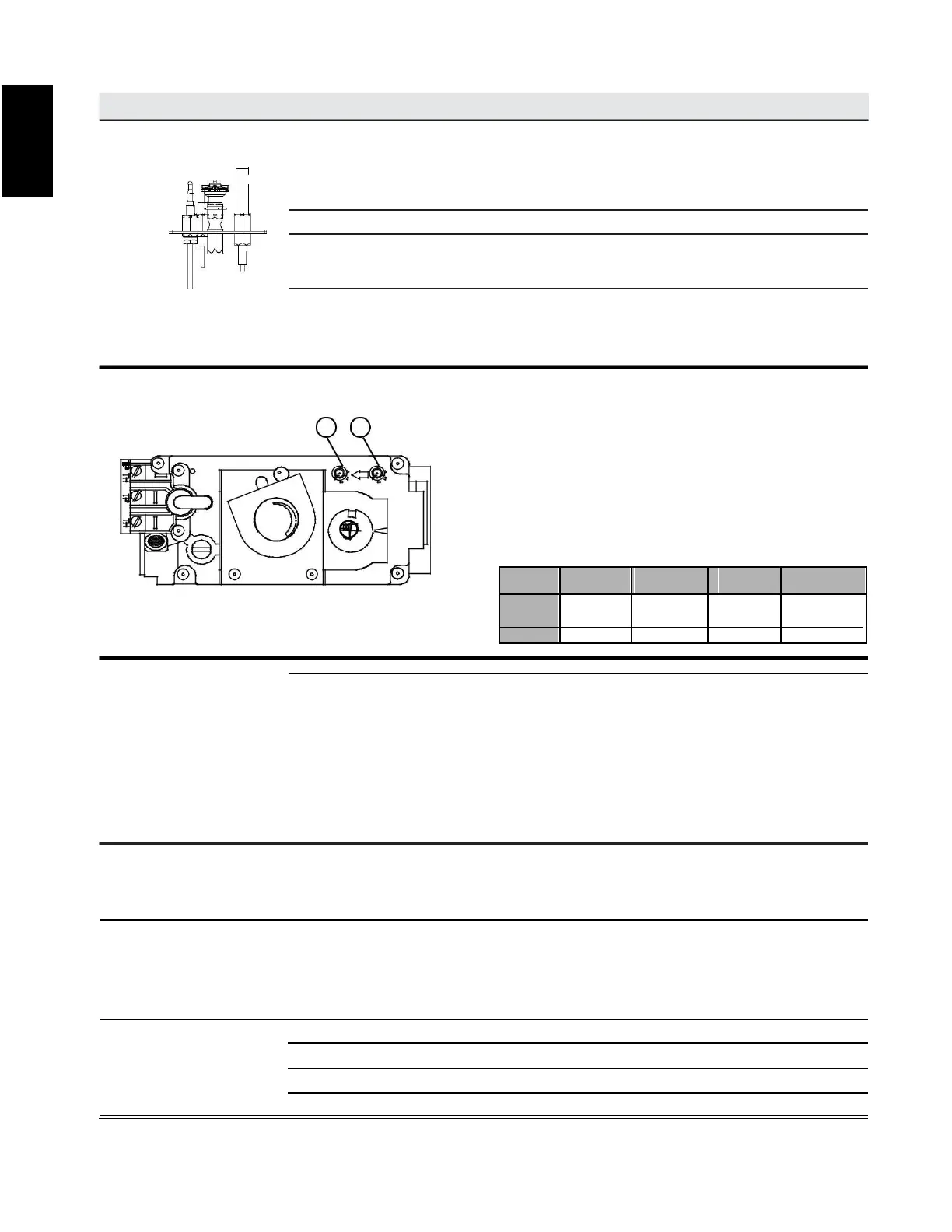

Inlet pressure can be checked by turning screw (A) counter-

clockwise 2 or 3 turns and then placing pressure gauge

tubing over the test point. Gauge should read as described

on the chart below. Check with main burner is operating on

Outlet pressure can be checked the same as above using

screw (B). Gauge should read as described on the chart

below. Check that main burner is operating on „HI‟.

AFTER TAKING PRESSURE READINGS, BE SURE TO TURN

SCREWS CLOCKWISE FIRMLY TO RESEAL. DO NOT OVER

Leak test with a soap and water solution.

Ensure air shutter opening is free of lint or other obstructions.

Check that the logs are correctly positioned.

Open air shutter to increase the primary air.

Check the input rate: check the manifold pressure and orifi ce

size as specifi ed by the rating plate values.

Check that the door gasketing is not broken or missing and

Check that both vent liners are free of holes and well sealed

Check that minimum rise per foot (meter) has been adhered

to for any horizontal venting.

White / grey fi lm forms.

Sulphur from fuel is being

Clean the glass with a recommended gas appliance glass

deposited on glass, logs or

combustion chamber surfaces.

DO NOT CLEAN GLASS WHEN HOT.

If deposits are not cleaned off regularly, the glass may

become permanently marked.

Ensure exhaust bracket gasket seal.

Check door seal and relief fl ap seal.

Check for chimney blockage.

Check that chimney is installed to building code.

Room is in negative pressure; increase fresh air supply.

Check cap gasket on the fl ue pipe assembly.

Wall switch is mounted upside down.

‟OFF‟ position; main burner

Remote wall switch is grounding.

comes on when gas knob is

Remote wall switch wire is grounding.

Check for ground (short); repair ground or replace wire.

W415-1679 / D / 03.09.18

Loading...

Loading...