ENGLISH

47

8.1. Periodic checks

The product in normal operation does not require any kind of maintenance. However, it is advisable to periodically check the current

absorption, the manometric head with the mouth closed and the maximum flow rate, which allows you to identify faults or wear in

advance. The mechanical seal does not normally require any control step. You will only have to check that there is no leak of any kind.

If there is a different seal, check the dedicated appendix.

8.2. Emptying the system

If you want to drain the water out of the system, proceed as follows:

1 Disconnect the power supply;

2 Turn on the delivery tap closes to the system so as to remove pressure from the system and empty it as much as possible;

3 If there is a check valve immediately downstream from the system (always recommended), close it so as not to let out the water

that is in the plant between the system and the first turned on tap;

4 Interrupt the suction pipe in the point closest to the system (it is always recommended to have a check valve immediately upstream

from the system) so as not to drain the whole suction system;

5 Remove the drainage cap and let out the water inside;

6 The water that is trapped in the delivery system downstream from the non-return valve integrated in the system can flow out at the

time of disconnecting the system, or on removing the cap of the second delivery (if not used).

Though essentially drained, the system is unable to expel all the water that it contains. During handling of the system after emptying it,

some small amounts of water may probably leak out from the system.

8.3. Modifications and spare parts

Any modification made without prior authorisation relieves the manufacturer of all responsibility.

Only if there is an integrated power cable, in the event of damage to the same, the repair must be carried out by specialized personnel

to prevent any risk.

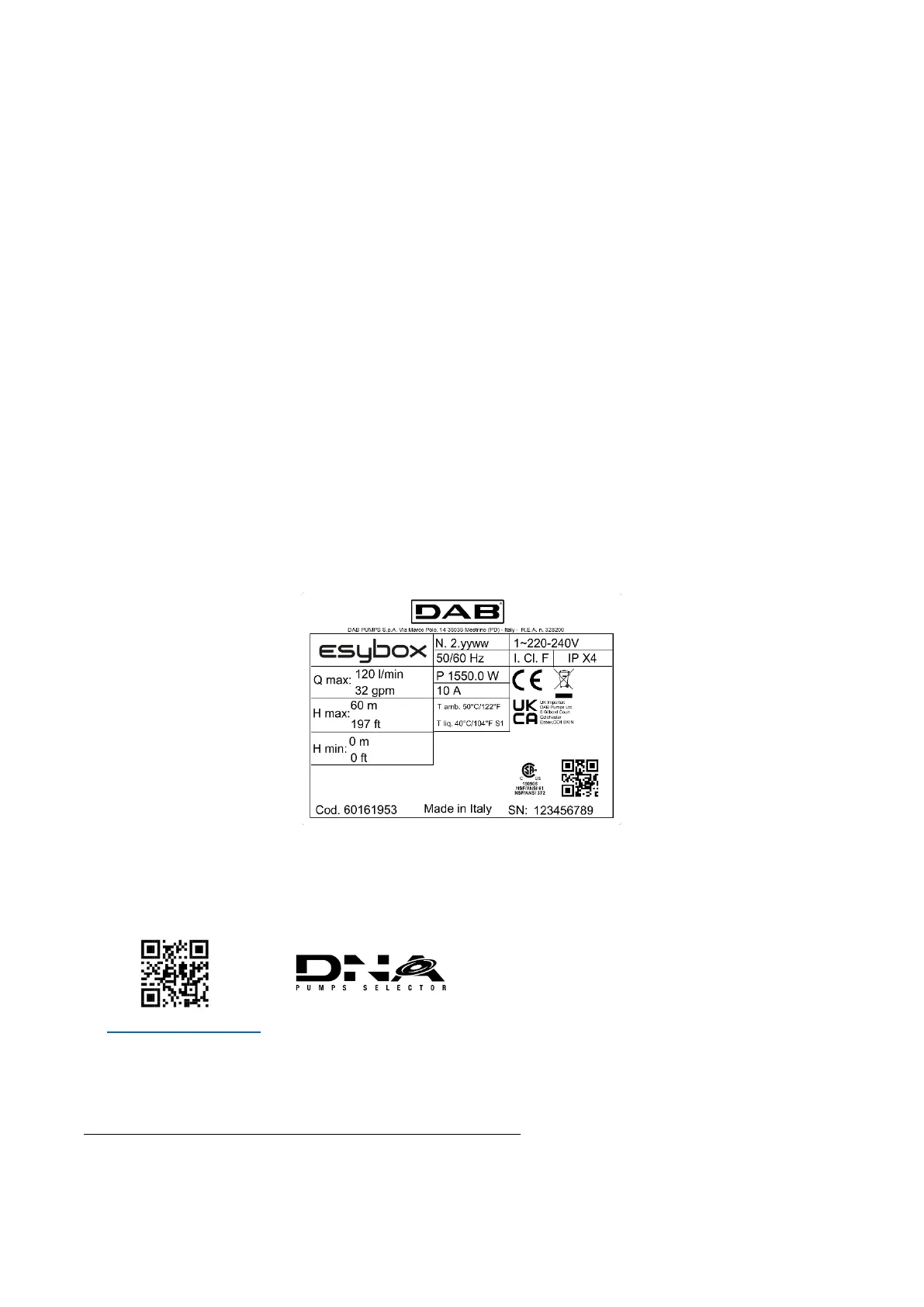

8.4. CE marking and minimum instructions for DNA

The image is for representative purposes only

Consult the Product configurator (DNA) available on the DAB PUMPS website.

The platform allows you to search for products by hydraulic performance, model or article number. Technical data sheets, spare parts,

user manuals and other technical documentation can be obtained.

https://dna.dabpumps.com/

9. DECLARATION OF CONFORMITY

For the product indicated in chapter 3.1, we declare that the device described in this instruction manual and marketed by us complies

with the relevant EU health and safety regulations.

A detailed and updated declaration of conformity is available with the product.

If the product is modified in any way without our consent, this statement will become invalid.

Loading...

Loading...