ENGLISH

68

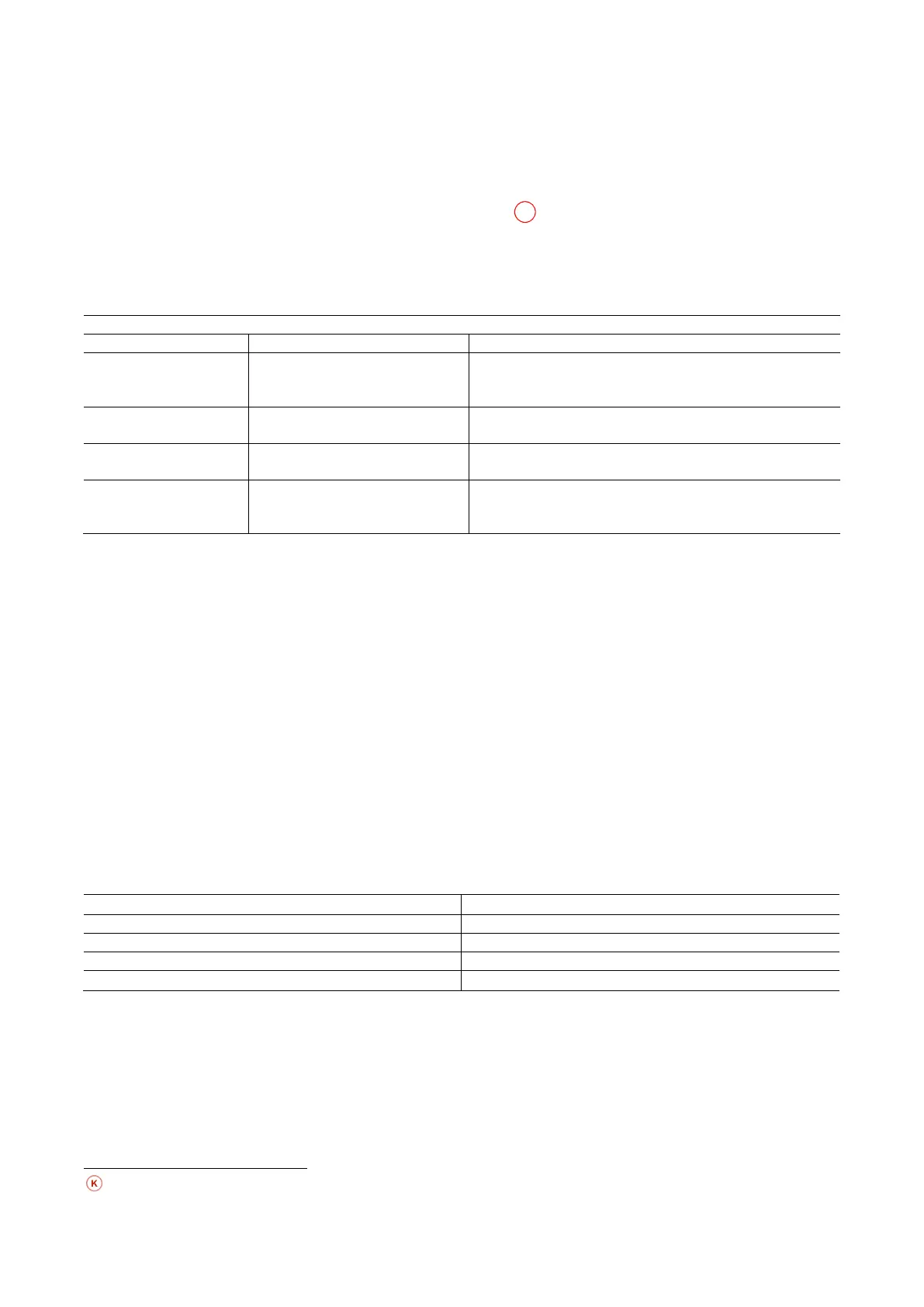

13.3.9. Self-reset of error conditions

For some malfunctions and blockage conditions, the system attempts automatic self-reset.

The auto self-reset procedure concerns in particular:

“BL” Blockage due to water lack

“PB”

Blockage due to line voltage outside specifications

Blockage due to overheating of the power stages

“OC” Blockage due to motor overload

“BP1” Blockage due to fault of the pressure sensor

“BP2”

Blockage due to fault of the Kiwa pressure sensor

For example, if the system is blocked due to water lack, the device automatically starts a test procedure to check whether the machine

is really left definitively and permanently dry. If during the sequence of operations an attempted reset is successful (for example, the

water comes back), the procedure is interrupted and normal operation is resumed.

Table 13 shows the sequences of the operations performed by the device for the different types of blockage.

Automatic resets of error conditions

BL Blockage due to water lack

- One attempt every 10 minutes for a total of 6 attempts.

- One attempt every hour for a total of 24 attempts

- One attempt every 24 hours for a total of 30 attempts

PB

Blockage due to line voltage outside

specifications

- It is reset when it returns to a specific voltage.

OT

Blockage due to overheating of the

power stages

- It is reset when the temperature of the power stages returns

within the specifications.

OC Blockage due to motor overload

- One attempt every 10 minutes for a total of 6 attempts.

- One attempt every hour for a total of 24 attempts.

- One attempt every 24 hours for a total of 30 attempts.

Table 22: Self-reset of blockages

13.4. Operation with control unit

The pump, alone or in a pumping unit, can be connected via radio communication to an external unit hereinafter referred to as the control

unit. Depending on the model, the control unit offers various functions.

Possible control units are:

• Esy I/O

The combination of one or more pumps with a control unit allows you to use:

• Digital Inputs

• Relay outputs

• Remote Pressure Sensor

• Modbus communication protocol

In the following, we will indicate with the term control unit functionality, the set of functions listed above and made available by the

various types of control unit

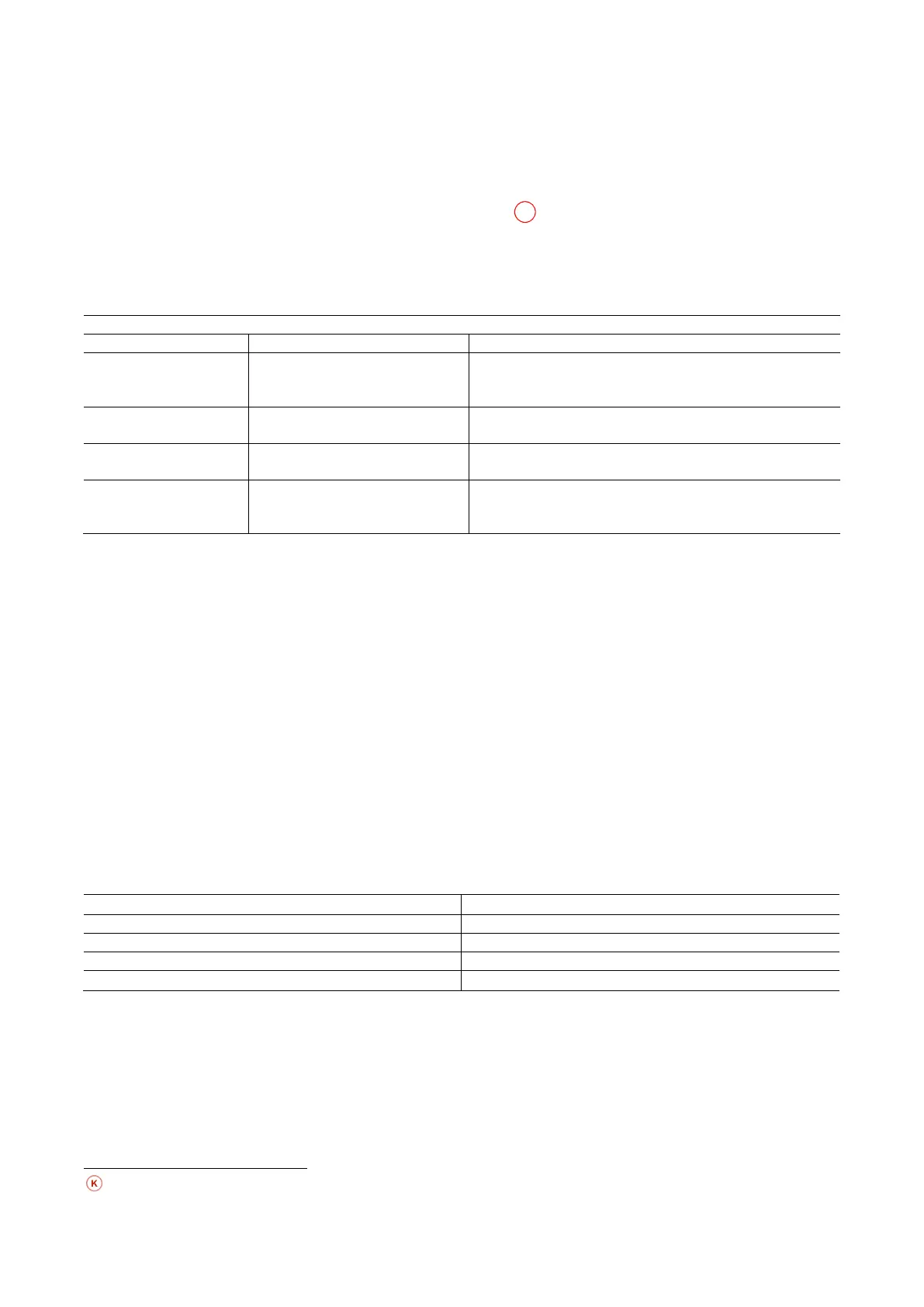

13.4.1. Functionality available from the control box

The available features are listed in the table below.

Opto-isolated digital inputs

Output relay with NO contact

Table 23: Functionality available from the control box

13.4.2. Electrical connections to user inputs and outputs

See control unit manual.

13.4.3. Setting Functions from the Control Unit

The default value of all inputs and the remote pressure sensor is Disabled, so in order to use them, they must be activated by the user

see chapter Setup of the auxiliary digitali inputs IN1, IN2, IN3, IN4 and PR: Remote pressure sensor.

Parameters available in version KIWA

Loading...

Loading...