ENGLISH

55

Disabled

Motor manually disabled

Error

Blocking error: the type of error is shown and described in the bottom left corner of the screen

KIWA Sensor Error

“Low suction pressure” error signal

Table 7: System Status Icons

Main Page: Auxiliary Functions Icons

Power Shower

Float

Sleep Mode

Table 8: Auxiliary Functions Icons

Footer: Indications on the status bar

Motor status manually disabled

Presence of an error preventing operation of the electropump

Indicates an Alarm that does not prevent operation of the electric pump

Table 9: Indications on the status bar

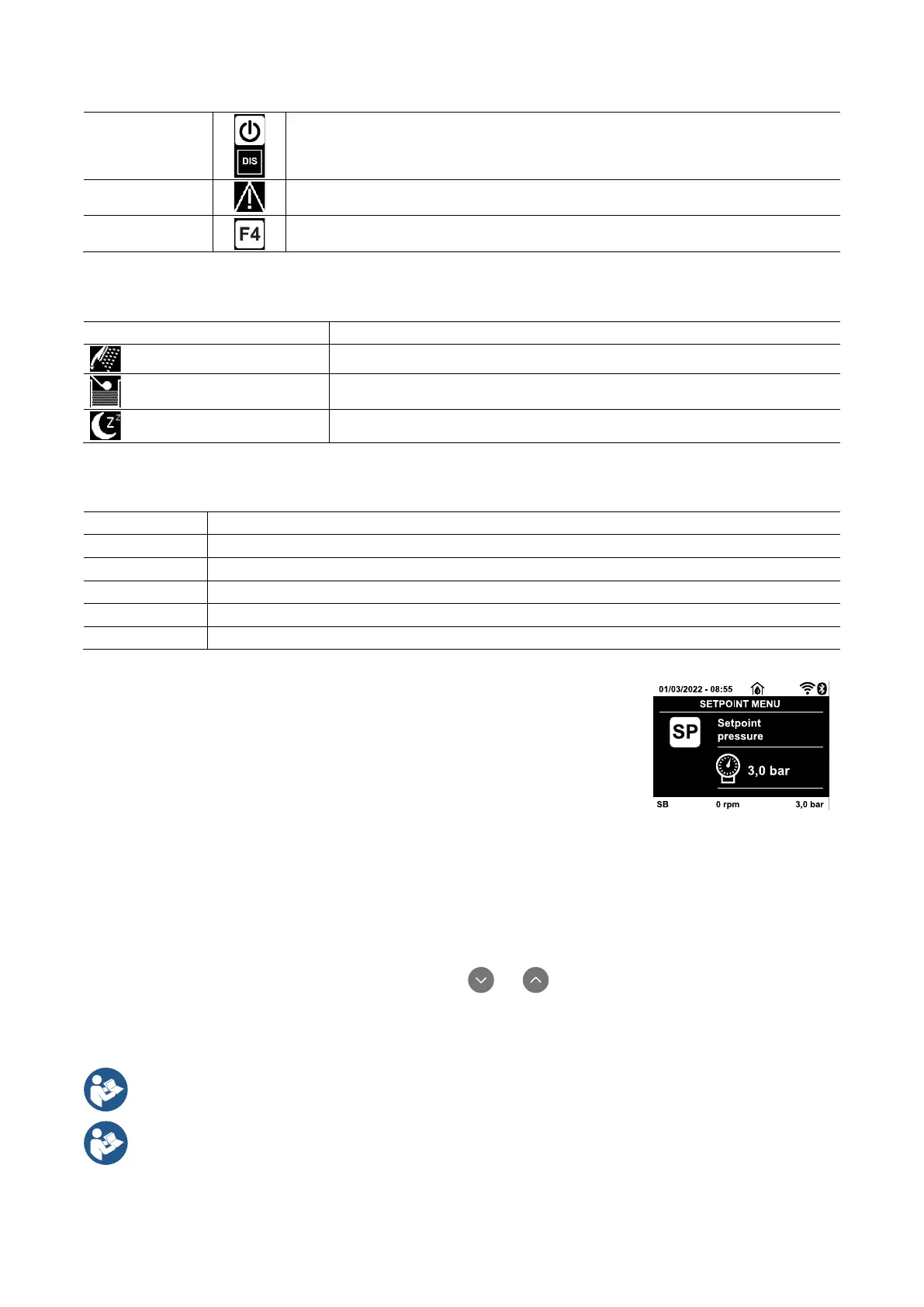

The other menu pages vary with the associated functions and are described later by type of

indication or setting. Once you have entered any menu, the bottom of the page always shows a

summary of the main operating parameters (running status or any fault, current speed and

pressure). This allows a constant view of the machine’s fundamental parameters.

Pages showing parameters can display: numerical values and units of measure of the current

item, values of other parameters linked to the setting of the current item, graphic bar, lists; see

Fig. 21.

Fig. 21: Display of a menu

parameter

13.1.5. Blocking parameter setting by Password

The device has a password-enabled protection system. If a password is set, the parameters of the device will be accessible and visible

but it will not be possible to change them. The password management system is in the “technical assistance” menu and is managed by

means of the parameter PW.

13.1.6. Enabling and disabling the motor

In normal operating conditions, pressing and then releasing both the and keys causes the blocking/release of the motor (self-

holding even after switching off). If there is a fault alarm, the operation described above resets the alarm. When the motor is disabled

this status is shown by the blinking white LED. This command can be activated from any menu page except RF and PW.

13.2. Meaning of the individual parameters

The inverter makes the system work at constant pressure. This regulation is appreciated if the hydraulic plant downstream from

the system is suitably sized. Plants made with pipes with too small a section introduce load losses that the equipment cannot

compensate; the result is that the pressure is constant on the sensors but not on the utility.

Plants that are excessively deformable can create the onset of oscillations; if this occurs, the problem can be solved by adjusting

the control parameters “GP” and “GI” (see paragraph

GP: Proportional gain coefficient and GI: Integral gain coefficient)

Loading...

Loading...