3-5

Inspecitions/Adjustments

Soak the element in solvent, and dry completely.

Soak in gear oil (SAE #80-90), and squeeze firmly

to remove excessive oil.

If the element is excessively contaminated or

damaged, replace it.

Assemble in the reverse order of the

disassembling.

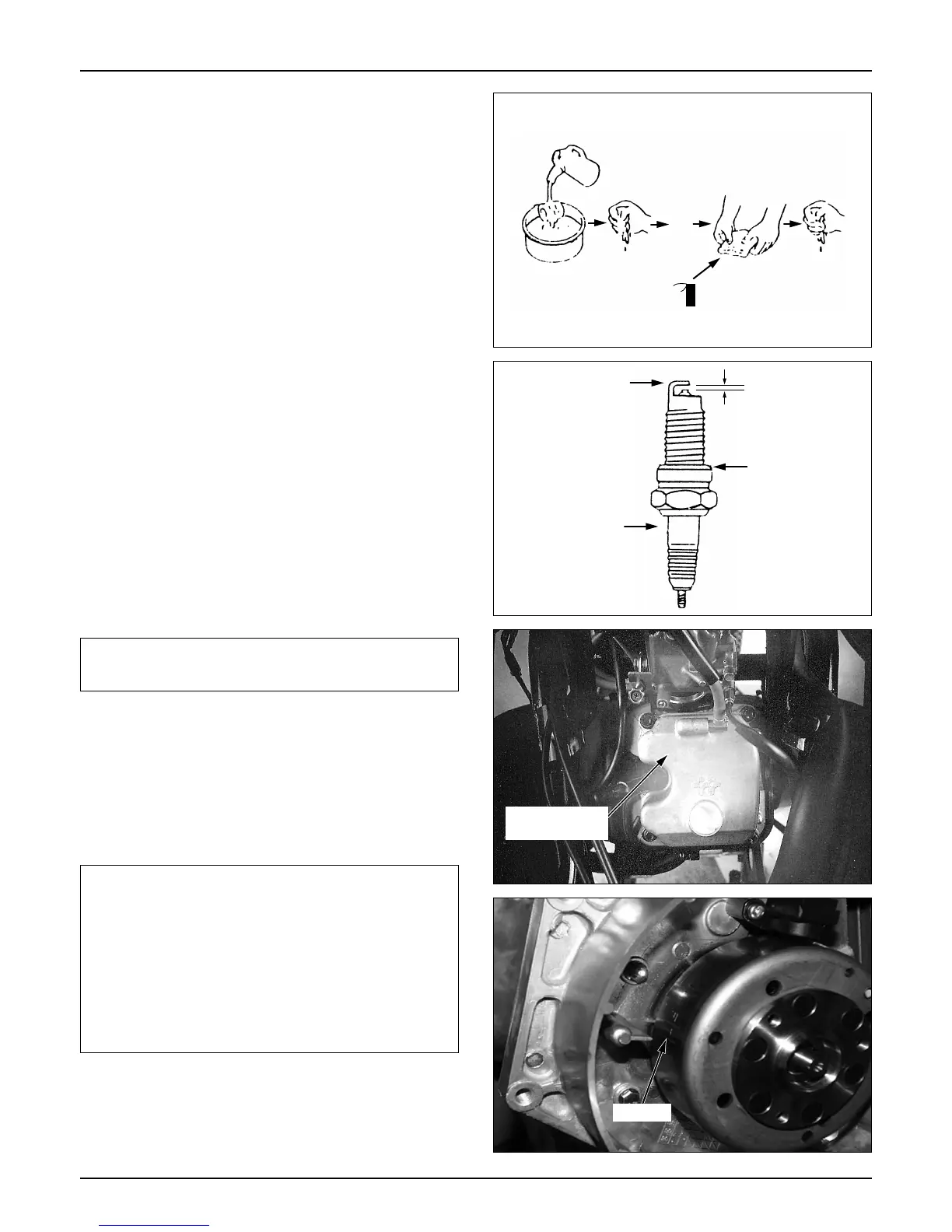

Spark Plug

Remove the plug maintenance cover.

Remove the spark plug cap and disassemble the

plug.

Check the plug for damage, contamination or

deposits.

If the spark plugs are severely contaminated or

damaged, replace with new ones. If the plugs

can be reused after removing only the carbon, use

plug cleaner and wire brush to clean the plugs.

Always use a feeler gauge to check the clearance.

Genuine plug: CREH-9

Spark plug clearance: 0.8-0.9mm

Torque value: 1.1kg-m(11N.m, 8ft-lb)

NOTE

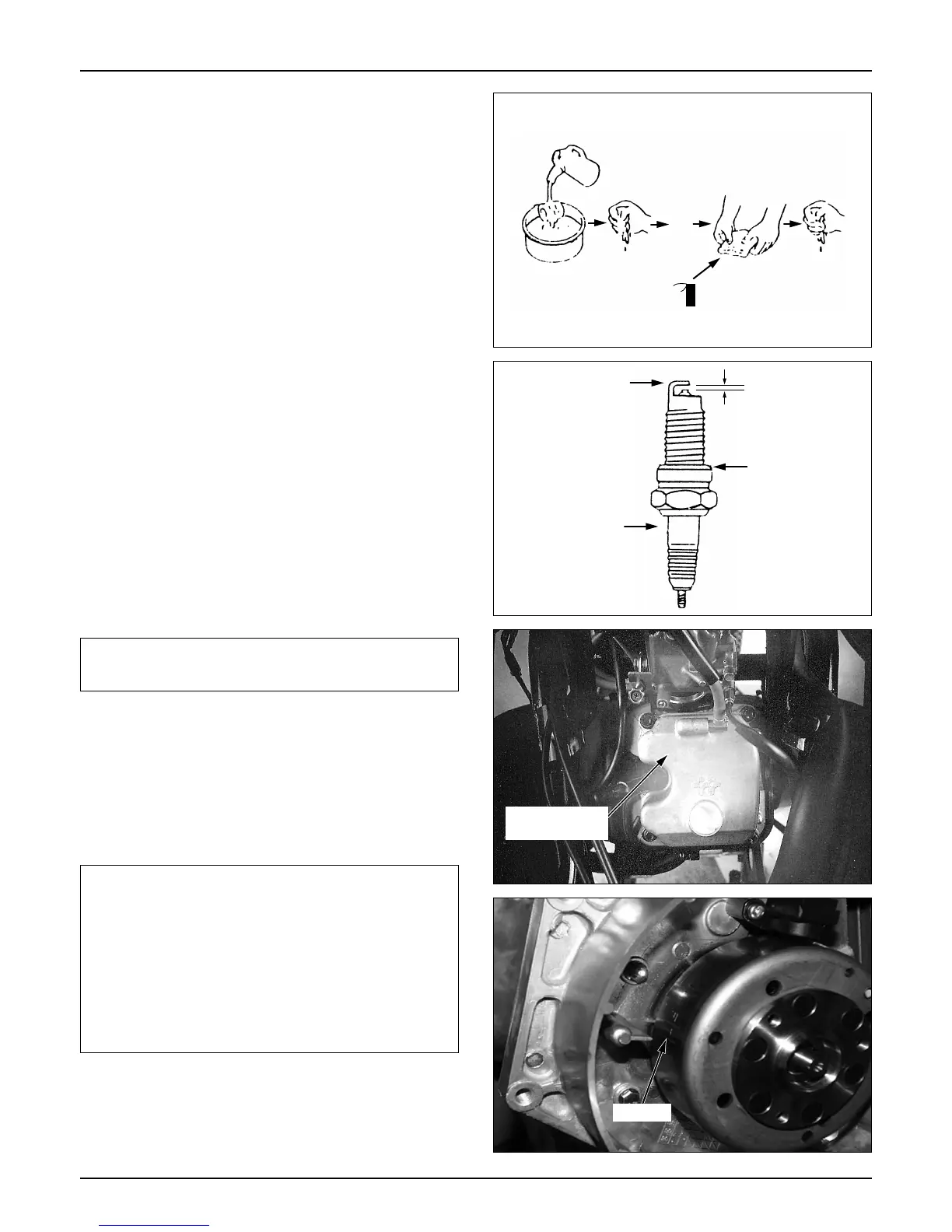

Valve Tappet Clearance

Remove the following parts.

-- Center cover. ( 4-4)

Loosen the 4 cylinder head bolts.

NOTE

Measure valve clearance with a feeler gauge.

Valve tappet clearance:

Intake: 0.12

±

0.02mm(0.05

±

0.001in)

Exhaust: 0.12

±

0.02mm(0.05

±

0.001in)

Carry out inspection/adjustment when the

engine is cold. (35/95F)

Remove the cylinder head cover.

Turn the flywheel counterclockwise, and match

the “T” mark on the flywheel with the index

mark on the R crank case cover.

The piston at this time must be at the top dead

center of the compression stroke.

First, manually tighten the plugs, and use a spark

plug wrench to tighten completely.

Cylinder

head cover

“T” mark

Wash

Squeeze

Dry

Gear oil

(#80-90)

Check

washer

for damage

Check for

cracks.

Check

gap

Squeeze

out oil

Oil

0.8~0.9mm

Loading...

Loading...