systeM aPPliCations

www.DaikinApplied.com 23 Vertical Stack WSHP • IM 986-11

Environment

This equipment is designed for indoor installation only. Shel-

tered locations such as attics, garages, etc., generally will not

provide sufcient protection against extremes in temperature

and/or humidity, and equipment performance, reliability, and

service life may be adversely affected.

CAUTION

Units must be checked for water leaks upon initial

water system start-up. Water leaks may be a result of

mishandling or damage during shipping. Failure by the

installing contractor to check for leaks upon start-up of the

water system could result in property damage.

Operating Limits

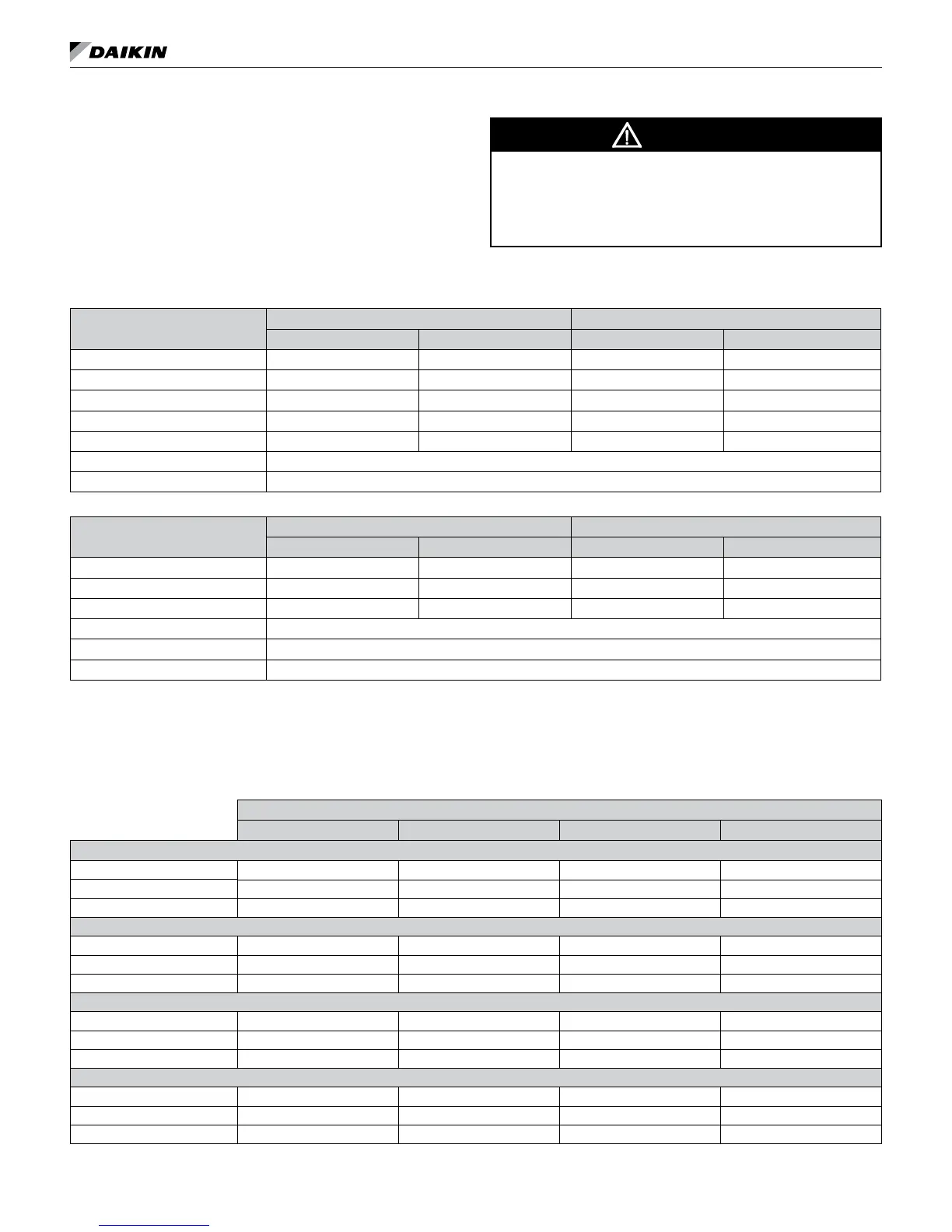

Table 10: Air limits in °F (°C)

Air Limits

Standard Range Units Geothermal Range Units

Cooling (DB/WB) Heating Cooling (DB/WB) Heating

Minimum Ambient Air

1

50°F/40°F (10°C/4°C) 50°F (10°C) 40°F/30°F (4°C/-1°C) 40°F (4°C)

Maximum Ambient Air

2

100°F/85°F (38°C/29°C) 85°F (29°C) 100°F/85°F (38°C/29°C) 85°F (29°C)

Minimum Entering Air

1

65°F/55°F (18°C/13°C) 50°F (10°C) 65°F/55°F (18°C/13°C) 50°F (10°C)

Common Design Entering Air 75°F/63°F (24°C/17°C) 70°F (21°C) 75°F/63°F (24°C/17°C) 70°F (21°C)

Maximum Entering Air

2

85°F/71°F (29°C/22°C) 80°F (27°C) 85°F/71°F (29°C/22°C) 80°F (27°C)

Minimum CFM/Ton 300

Maximum CFM/Ton 450

Table 11: Fluid limits

Fluid Limits

Standard Range Units Geothermal Range Units

Cooling Heating Cooling Heating

Minimum Entering Fluid 55°F (13°C) 55°F (13°C) 30°F (-1°C) 20°F (-6°C)

Common Design Entering Fluid 85-90°F (29-32°C) 70°F (21°C) 90°F (32°C) 35-60°F (1.5-16°C)

Maximum Entering Fluid 120°F (49°C) 90°F (32°C) 120°F (49°C) 90°F (32°C)

Minimum GPM/Ton 1.5

Nominal GPM/Ton 3.0

Maximum GPM/Ton 4.0

Notes: 1. Maximum and minimum values may not be combined.If one value is at maximum or minimum, the other two conditions may not exceed

the normal condition for standard units. Geothermal range units may combine any two maximum conditions, but not more than two, with

all other conditions being normal conditions.

2. This is not a normal or continuous operating condition. It is assumed that such a start-up is for the purpose of bringing the building space

up to occupancy temperature.

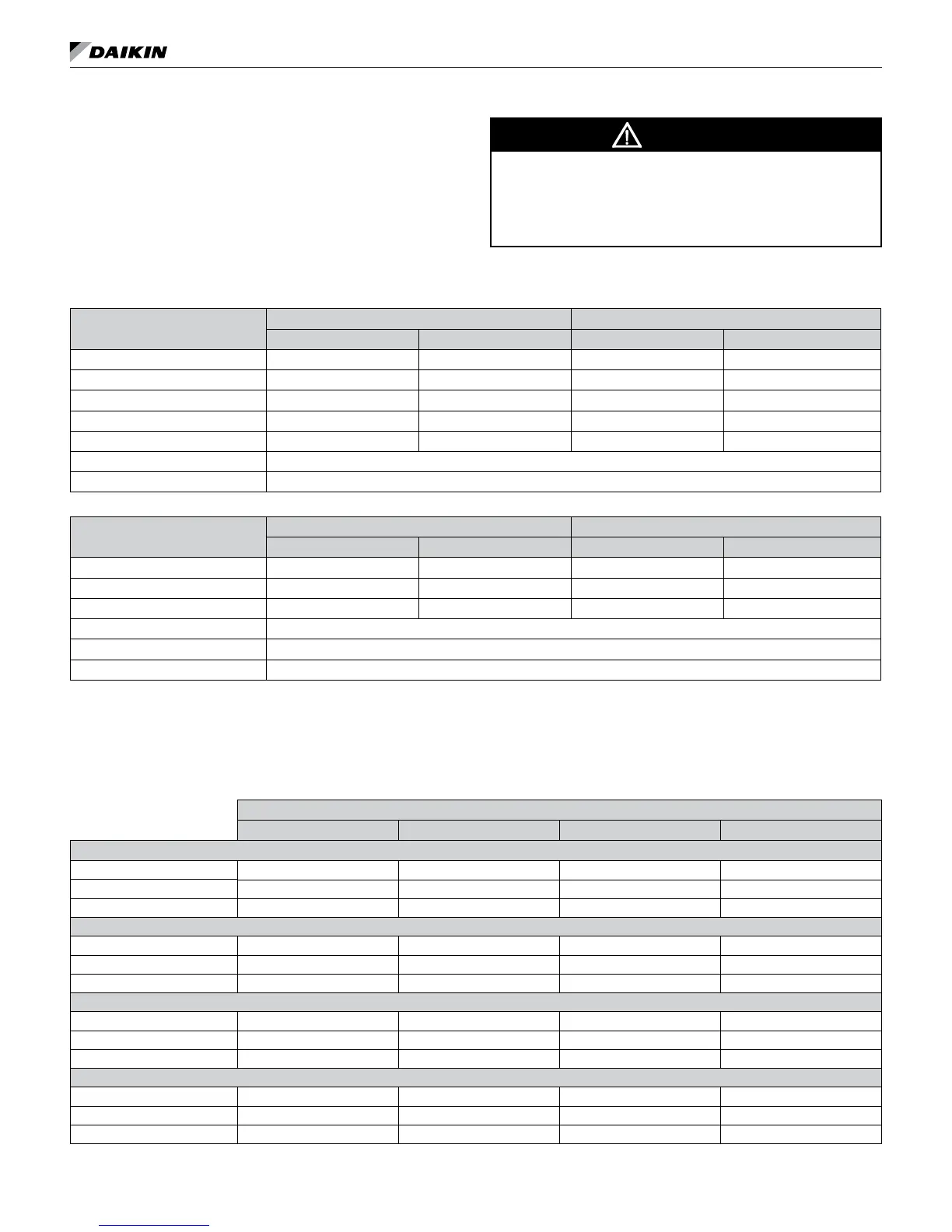

Antifreeze Correction Factors

Antifreeze % by weight

15% 25% 35% 45%

Ethanol

Cooling Capacity

0.985 – – –

Heating Capacity 0.9825 – – –

Pressure Drop

1.04

Ethylene Glycol

Cooling Capacity

0.9935 0.9895 0.985 0.981

Heating Capacity 0.9865 0.9795 0.973 0.965

Pressure Drop

1.10 1.16 1.22 1.27

Methanol

Cooling Capacity

0.985 – – –

Heating Capacity 0.9825 – – –

Pressure Drop

1.04 – – –

Propylene Glycol

Cooling Capacity

0.985 0.975 0.965 0.955

Heating Capacity 0.981 0.9685 0.952 0.936

Pressure Drop

1.11 1.20 1.31 1.40

Loading...

Loading...