FC 300 Instruction Manual

How to Install

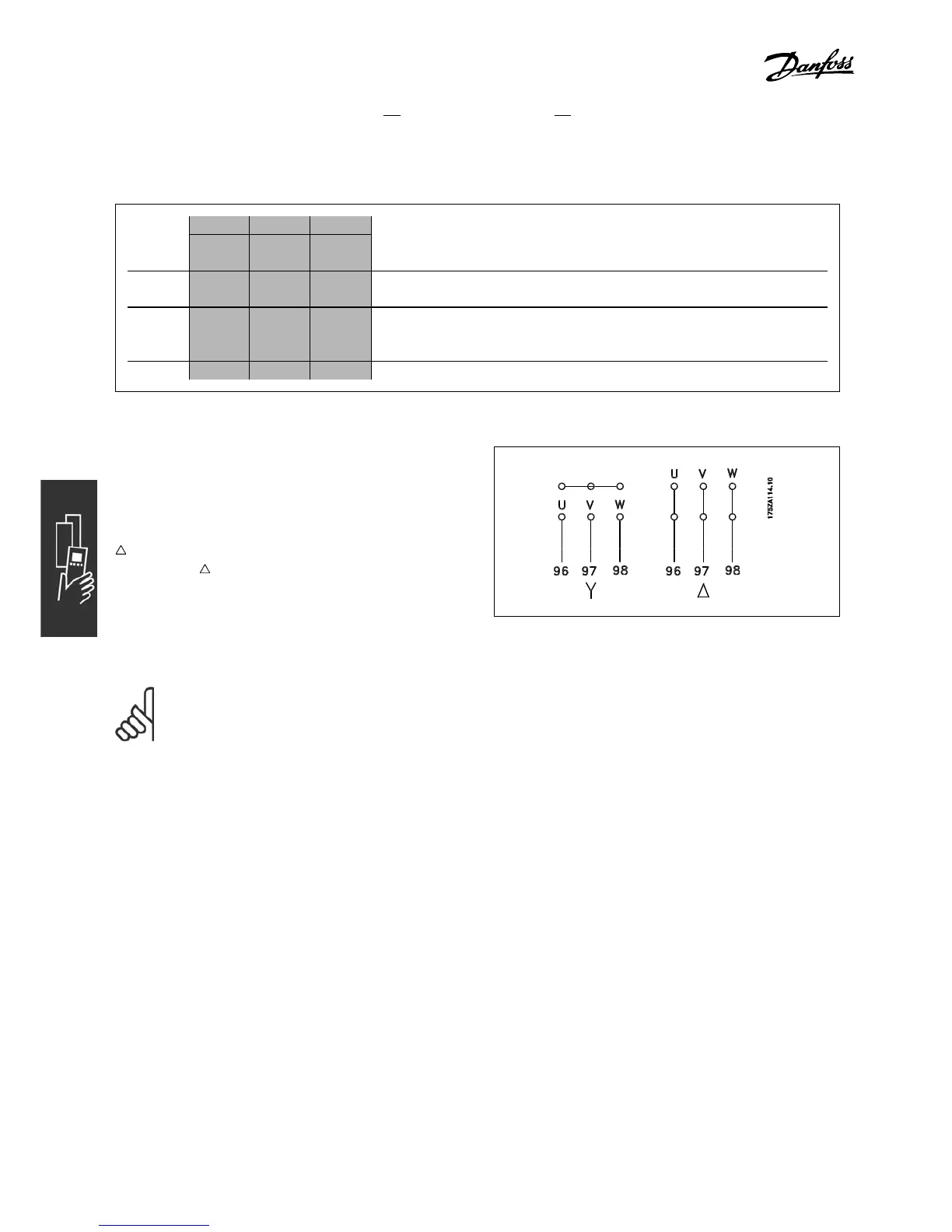

No. 96 97 98 Motor voltage 0-100%

U V W of AC line voltage.

3 wires out of motor

U1 V1 W1

W2 U2 V2

6 wires out of m otor, Delta-connected

U1 V1 W1 6 wires out of motor, Star-connected

U2, V2, W2 to be interconnected separately

No. 99 Ground connection

PE

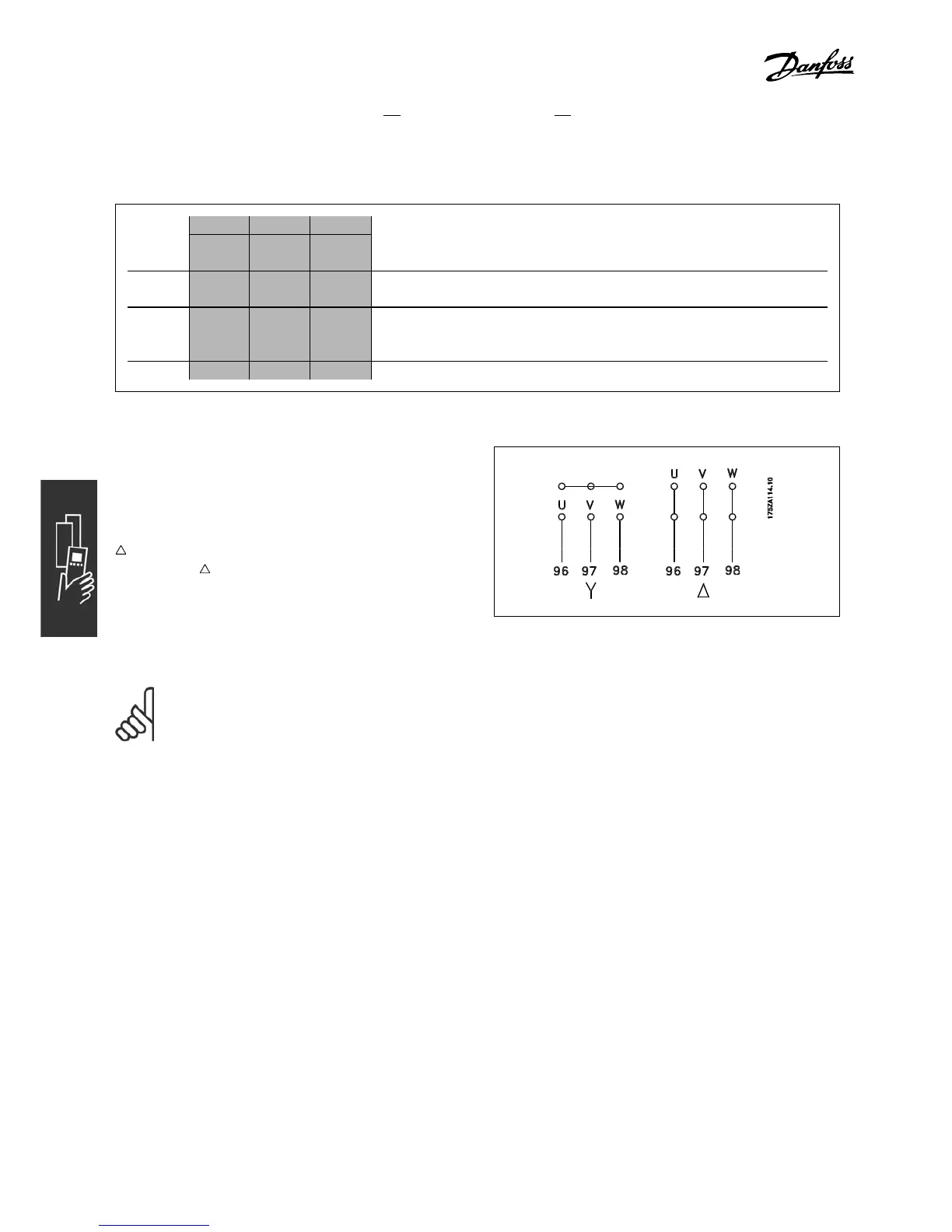

All types of three-phase asynchronous standard

motors can be connected to the FC 300. Normally,

small motors are star-connecte d (230/400 V,

/Y). Large motors are normally delta-connected

(400/690 V,

/Y). Refer to the motor nameplate

for correct connection mode and voltage.

NOTE

In motors without phase in sulation paper or other insulation reinforcement suitable for operation

with voltage supply (such as adjustable frequency drive), fit an LC filter on the output of the FC 300.

" Motor cables

See Technical data for correct sizing of m otor cable cross-section and length. Always comply

with national and local regulations on cable cross-sec tion.

• Use a shielded/armoured motor cable to comply with EMC emission specifications

unless otherwise stated for the RFI filter used.

• Keep the m ot or cable as short as possible to reduce the noise level and leakage currents.

• Connect the motor cable shield to the decoupling plate of the FC 300 and to the metal cabinet of the motor.

• Make the shield connections with the largest possible surface area (cable clamp). This is

done by using the supplied installation devices in the FC 300.

• Avoid mounting with twisted screen end s (pigtails), which will spoil high frequency screening effects.

• If it is necessary to split the shield to install a motor isolator or motor r elay, the shield

must be continued with the lowest possible HF impedance.

20

MG.33.A6.22 - VLT is a registered Danfoss trademark

Loading...

Loading...