Service Monitor User Manual

Danfoss Turbocor Compressors Inc. 35

ECD-00007M Rev. 1

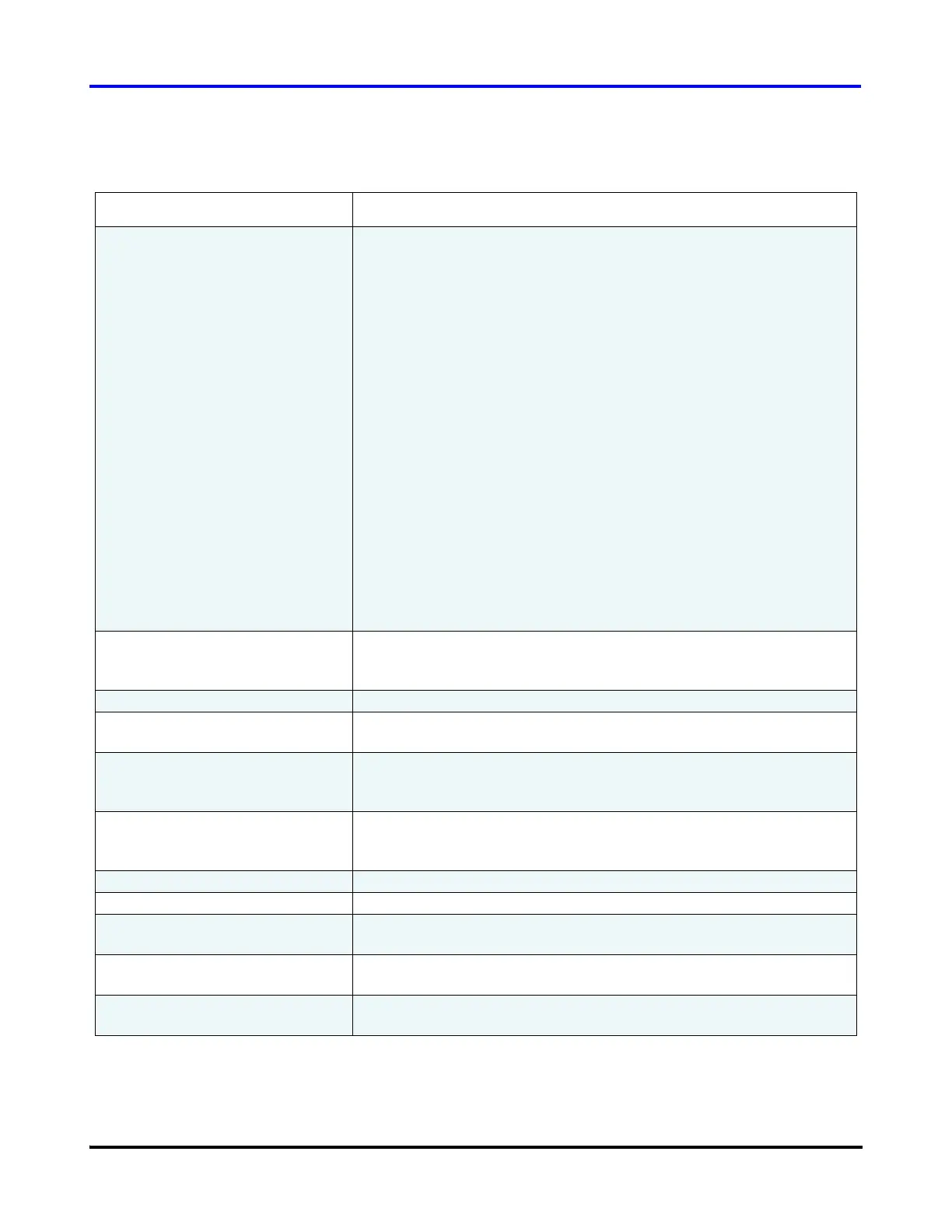

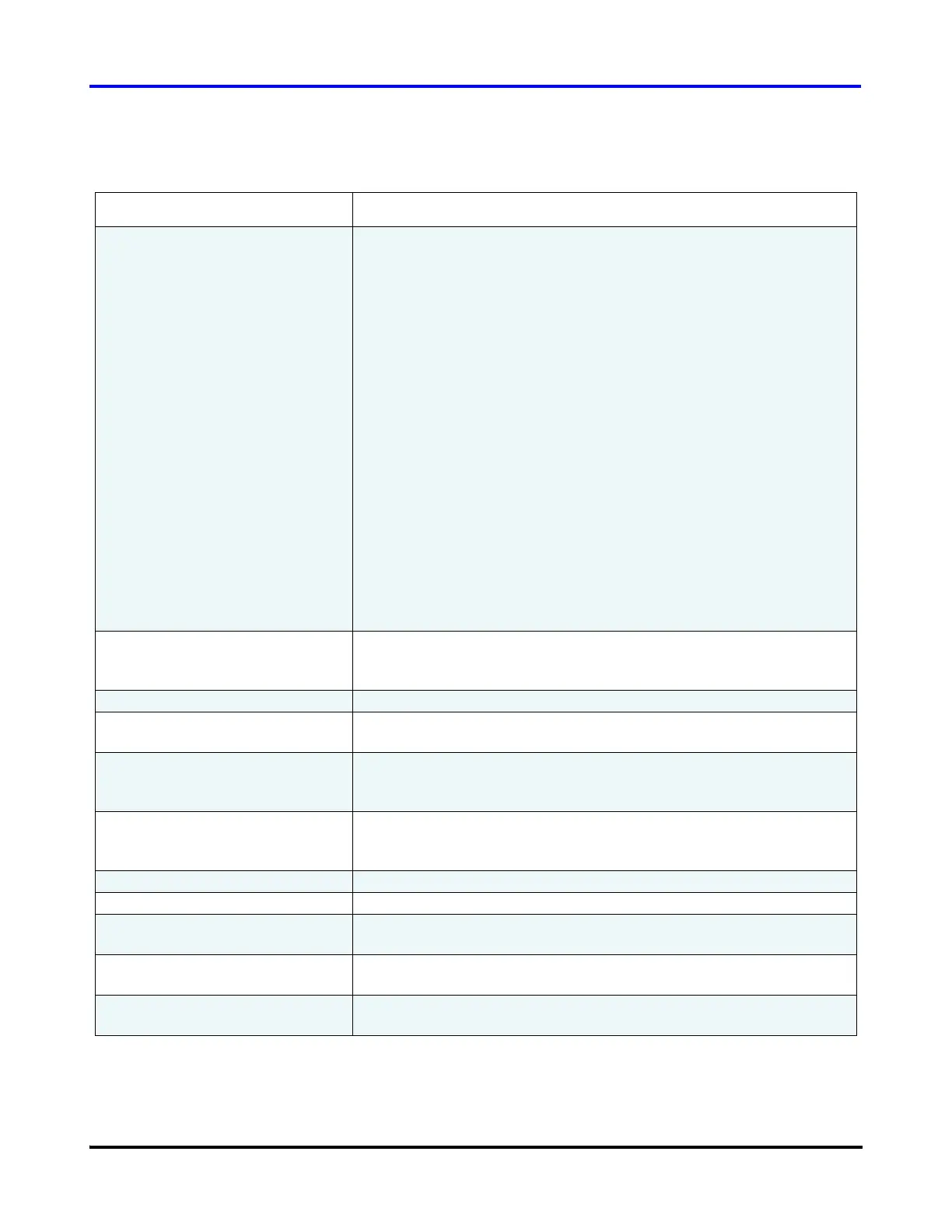

Table 12 Electronic Valve Data / Tuning Parameters (Stepper Motors)

Parameter Description

Control Mode Selects which control variable will be maintained by the stepper motor

output. The options are:

1. Superheat control using the compressor flange temperature and

pressure (this mode is not recommended as the temperature at the

compressor flange is influenced by external factors).

2. Superheat control using the compressor flange pressure and a

10K thermistor that is connected to the terminals labeled “ENTRY”

on the Chiller Interface module.

3. Superheat control using the compressor flange pressure and a

10K thermistor that is connected to the terminals labeled “LIQT” on

the Chiller Interface module.

4. Superheat control using an external temperature and pressure

sensor connected to the terminals labeled “SPARE T” & “SPARE

P” on the Chiller Interface module.

5. Liquid Level 1 control using a level sensor connected to the

terminals on the Chiller Interface module labeled “LIQ LEV1”.

6. Liquid Level 2 control using a level sensor connected to the

terminals on the Chiller Interface module labeled “LIQ LEV2”.

7. Load Balance control uses the compressor’s own internal control

algorithm to determine the best mix of speed control, inlet guide

vane opening and load balance valve opening.

Auto/Manual In automatic mode the compressor has complete control over the

stepper motor output. In Manual mode the user is able to enter the

valve position.

Process Value Value of the controlled variable selected from the Control Mode.

Valve % Open Ratio of the actual number of steps sent to the stepper motor over the

maximum number of steps the motor is allowed to drive.

Stepper Startup % Percentage of maximum steps sent to the motor on start of the

compressor. The stepper motor will hold at this position until the

stepper start delay timer has expired.

Stepper Start Position Delay Amount of time from compressor start to hold the number of steps sent

to the motor at the stepper startup %. Value is in seconds and starts to

count down when the drive enables.

Stepper Control Setpoint Desired value of the controlled variable.

Stepper Control Loop Speed Reaction time of the control loop to a process error.

Stepper Minimum Close % The minimum close position for the valve while the compressor is

spinning.

Maximum Step Count Number of steps from fully closed to fully open for the installed stepper

motor driven device.

Graph Displays the “Process Value” parameter with respect to time. The time

corresponds to the PC system time, and is displayed in HH:MM format.

Loading...

Loading...