4.2.2 Receiving the Frequency Converter

When receiving the frequency converter make sure that

the packaging is intact, and be aware of any damage that

might have occurred to the unit during transport. In case

damage has occurred, contact immediately the shipping

company to claim the damage.

4.2.3 Transportation and Unpacking

Before unpacking the frequency converter it is

recommended that it is located as close as possible to the

final installation site.

Remove the box and handle the frequency converter on

the pallet, as long as possible.

4.2.4

Lifting

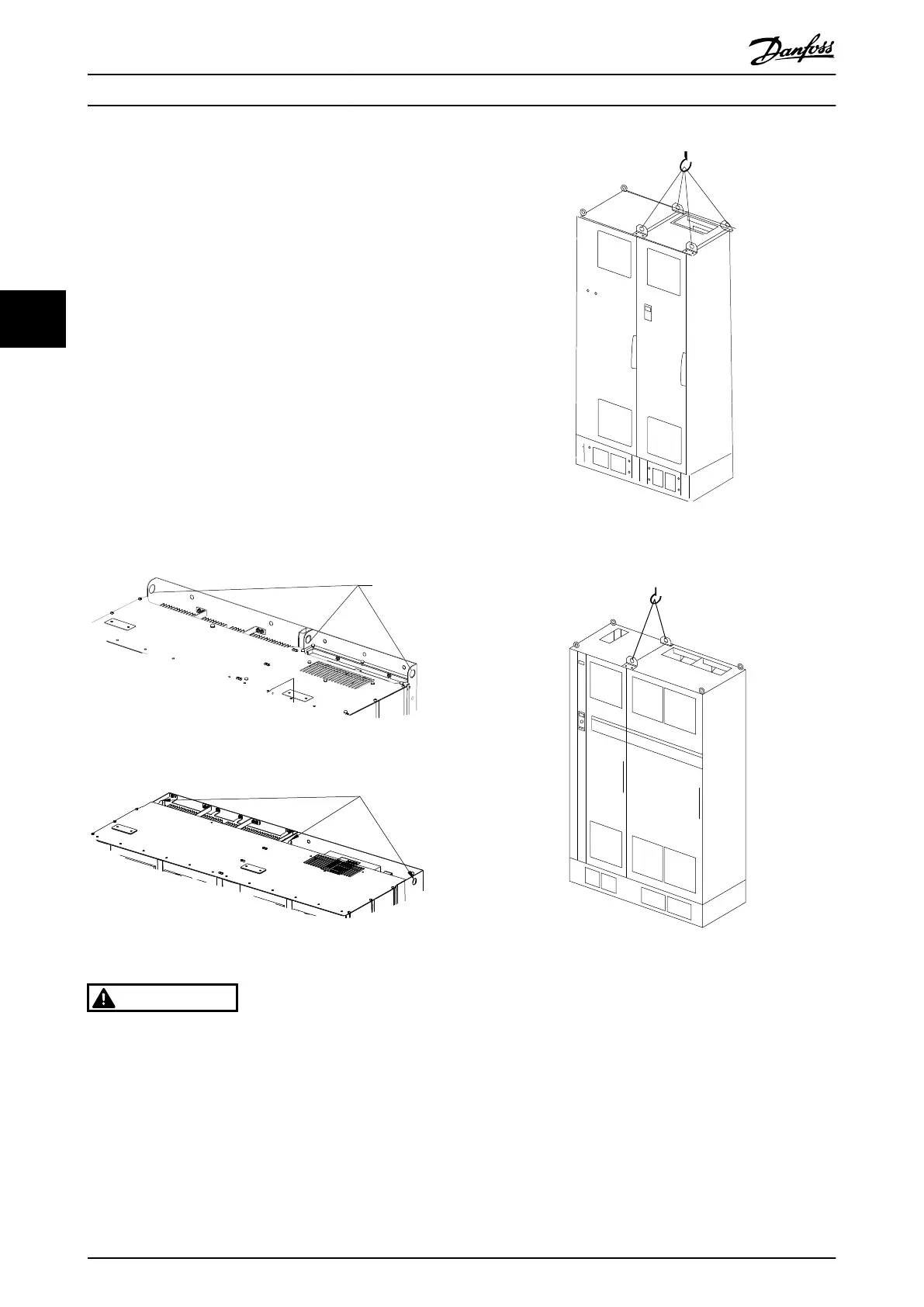

Always lift the frequency converter in the dedicated lifting

eyes. For all D and E frames, use a bar to avoid bending

the lifting holes of the frequency converter.

Illustration 4.2 Recommended lifting method, frame sizes D13

Illustration 4.3 Recommended lifting method, frame sizes E9

WARNING

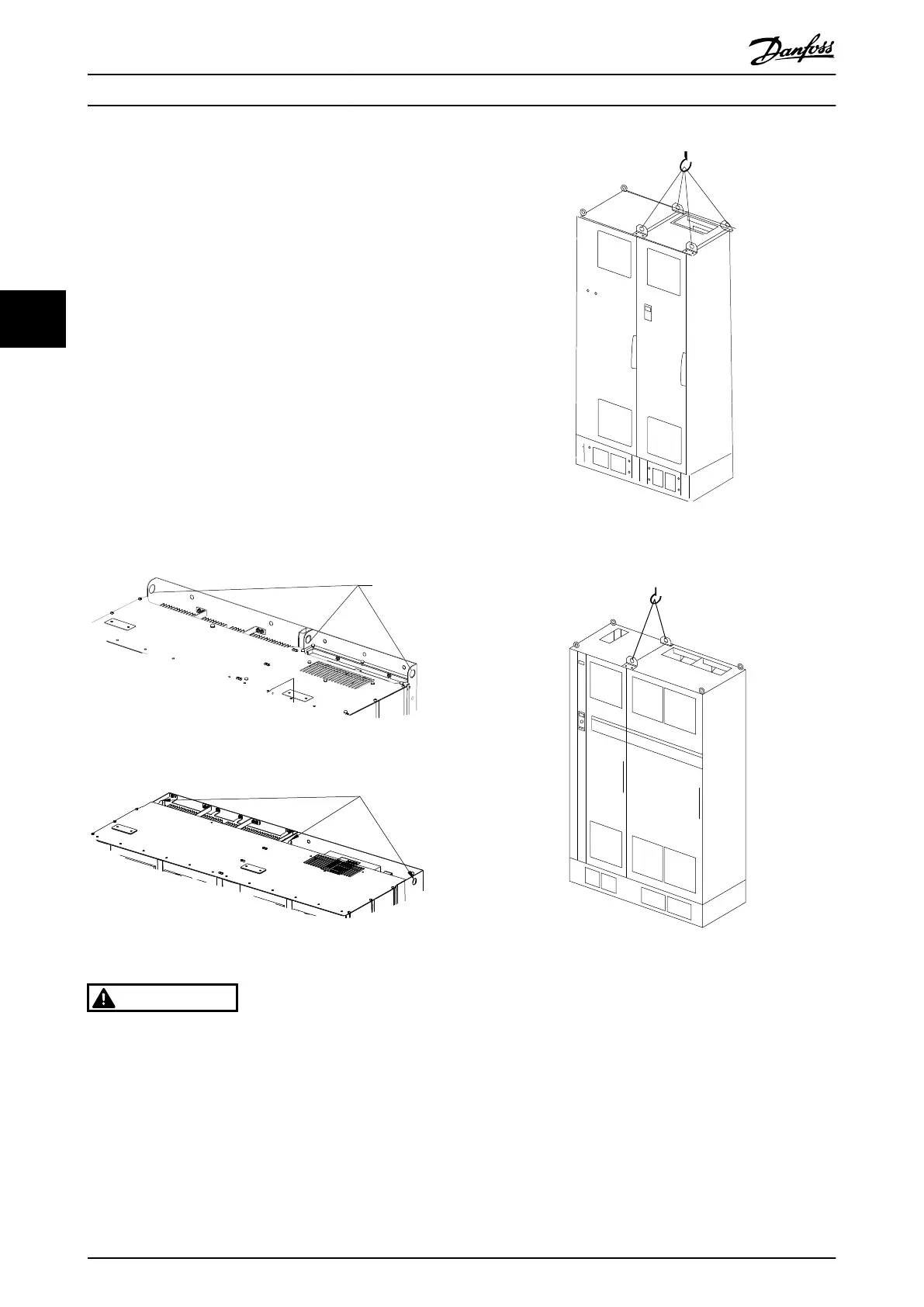

The lifting bar must be able to handle the weight of the

frequency converter. See 4.2.5 Mechanical Dimensions for

the weight of the different frame sizes. Maximum diameter

for bar is 2.5 cm (1 inch). The angle from the top of the

frequency converter to the lifting cable should be 60° or

greater.

Illustration 4.4 Recommended lifting method, frame size F18 -

filter section.

Illustration 4.5 Recommended lifting method, frame size F18 -

drive section.

NOTE

The plinth is provided in the same packaging as the unit

but is not attached to frame size F during shipment. The

plinth is required to allow airflow to the frequency

converter to provide proper cooling. The F frames should

be positioned on top of the plinth in the final installation

location. The angle from the top of the drive to the lifting

cable should be 60° or greater.

In addition to the drawing above a spreader bar is an

acceptable way to lift the F Frame.

How to Install VLT Automation Low Harmonic Drive Operating Instructions

14 MG34O202 - VLT

®

is a registered Danfoss trademark

44

Loading...

Loading...