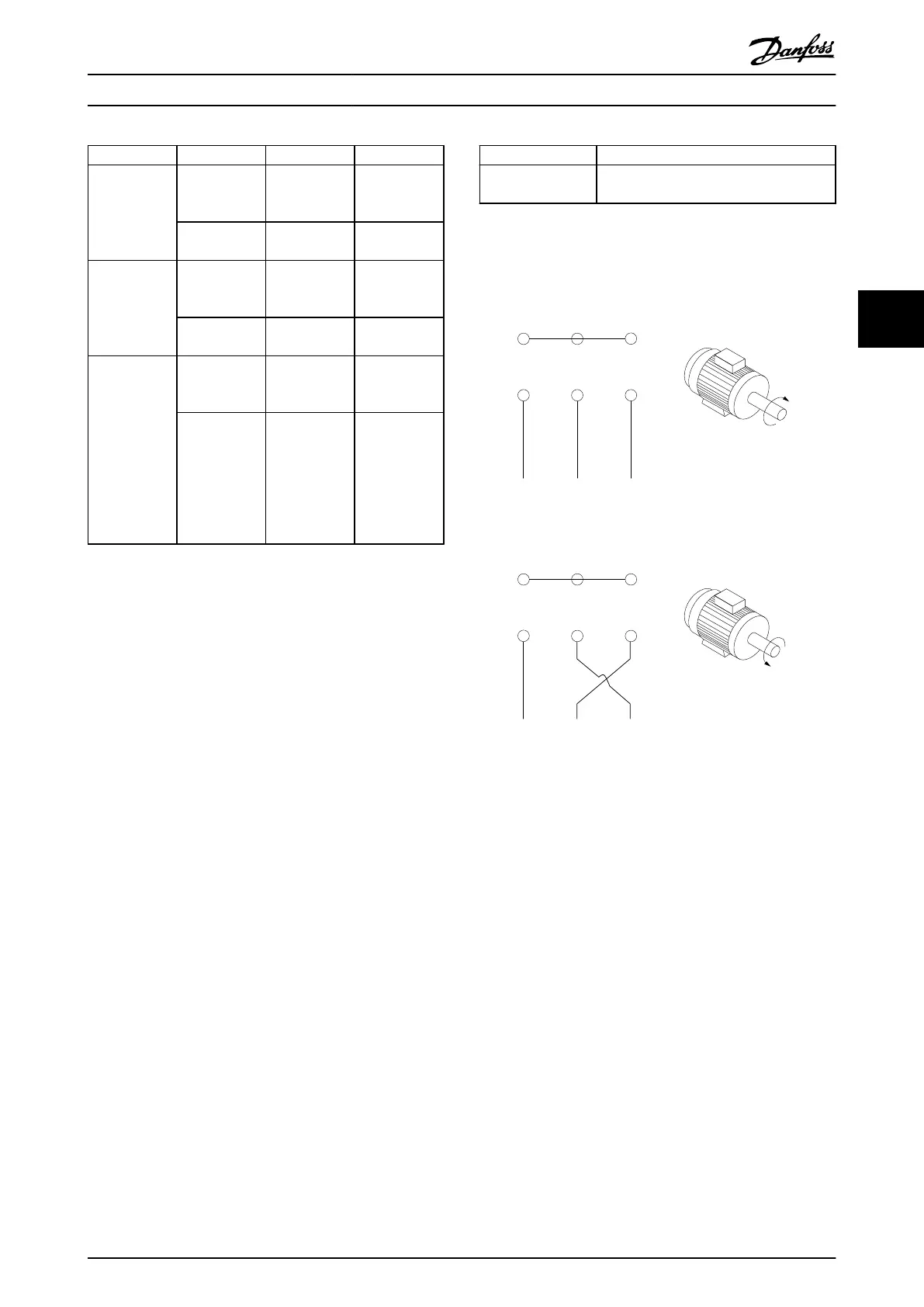

Frame size Terminal Torque Bolt size

D

Mains

Motor

19-40 Nm

(168-354 in-

lbs)

M10

Load sharing

Brake

8.5-20.5 Nm

(75-181 in-lbs)

M8

E

Mains

Motor

Load sharing

19-40 Nm

(168-354 in-

lbs)

M10

Brake 8.5-20.5 Nm

(75-181 in-lbs)

M8

F

Mains

Motor

19-40 Nm

(168-354 in-

lbs)

M10

Load sharing

Brake

Regen

19-40 Nm

(168-354 in-

lbs)

8.5-20.5 Nm

(75-181 in-lbs)

8.5-20.5 Nm

(75-181 in-lbs)

M10

M8

M8

Table 4.25 Torque for terminals

4.6.6

Shielded Cables

NOTE

Danfoss recommends to use shielded cables between the

LCL filter and the AFE unit. Unshielded cables can be

between transformer and LCL filter input side.

It is important that shielded and armoured cables are

connected in a proper way to ensure the high EMC

immunity and low emissions.

The connection can be made using either cable glands or

clamps:

•

EMC cable glands: Generally available cable

glands can be used to ensure an optimum EMC

connection.

•

EMC cable clamp: Clamps allowing easy

connection are supplied with the frequency

converter.

4.6.7

Motor Cable

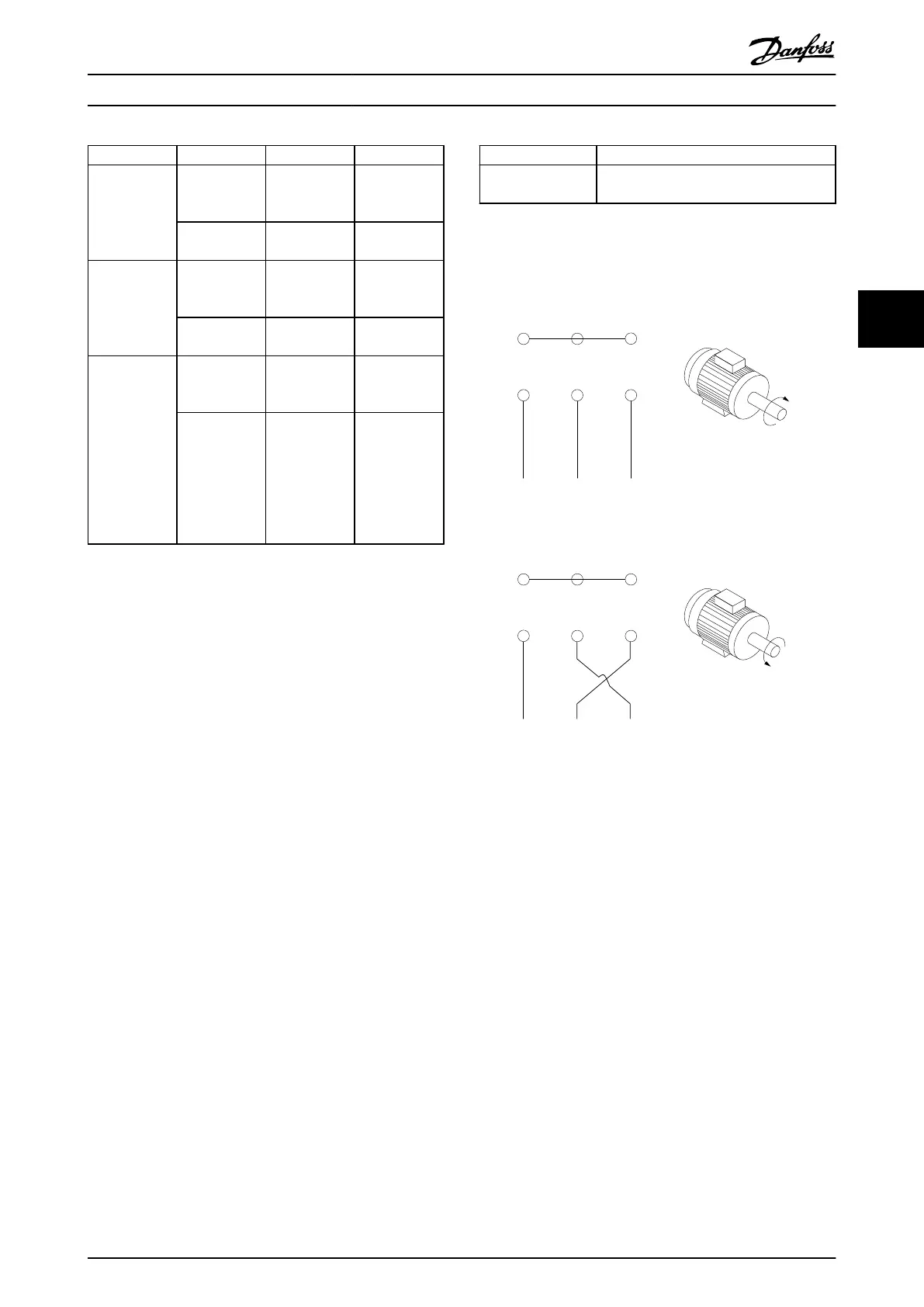

The motor must be connected to terminals U/T1/96, V/

T2/97, W/T3/98 located on the far right of the unit. Earth

to terminal 99. All types of three-phase asynchronous

standard motors can be used with a frequency converter

unit. The factory setting is for clockwise rotation with the

frequency converter output connected as follows:

Terminal No.

Function

96, 97, 98, 99 Mains U/T1, V/T2, W/T3

Earth

Table 4.26

•

Terminal U/T1/96 connected to U-phase

•

Terminal V/T2/97 connected to V-phase

•

Terminal W/T3/98 connected to W-phase

96 97

U V

96 97 98

U V W

98

W

130HA036.10

Illustration 4.30

NOTE

The direction of rotation can be changed by switching two

phases in the motor cable or by changing the setting of

4-10 Motor Speed Direction.

Motor rotation check can be performed using 1-28 Motor

Rotation Check and following the steps shown in the

display.

F frame Requirements

Motor phase cable quantities must be multiples of 2,

resulting in 2, 4, 6, or 8 (1 cable is not allowed) to obtain

equal amount of wires attached to both inverter module

terminals. The cables are required to be equal length

within 10% between the inverter module terminals and the

first common point of a phase. The recommended

common point is the motor terminals.

Output junction box requirements: The length, minimum

2.5 meters, and quantity of cables must be equal from

each inverter module to the common terminal in the

junction box.

How to Install VLT Automation Low Harmonic Drive Operating Instructions

MG34O202 - VLT

®

is a registered Danfoss trademark 45

4 4

Loading...

Loading...