4) The typical power loss is at nominal load

conditions and expected to be within +/-15%

(tolerence relates to variety in voltage and cable

conditions). Values are based on a typical motor

efficiency (eff2/eff3 border line). Motors with

lower efficiency will also add to the power loss in

the frequency converter and opposite. If the

switching frequency is increased comed to the

default setting, the power losses may rise signifi-

cantly.LCP and typical control card power

consumptions are included. Further options and

customer load may add up to 30 W to the losses.

(Though typical only 4 W extra for a fully loaded

control card, or options for slot A or slot B, each).

Although measurements are made with state of

the art equipment, some measurement

inaccuracy must be allowed for (+/-5%).

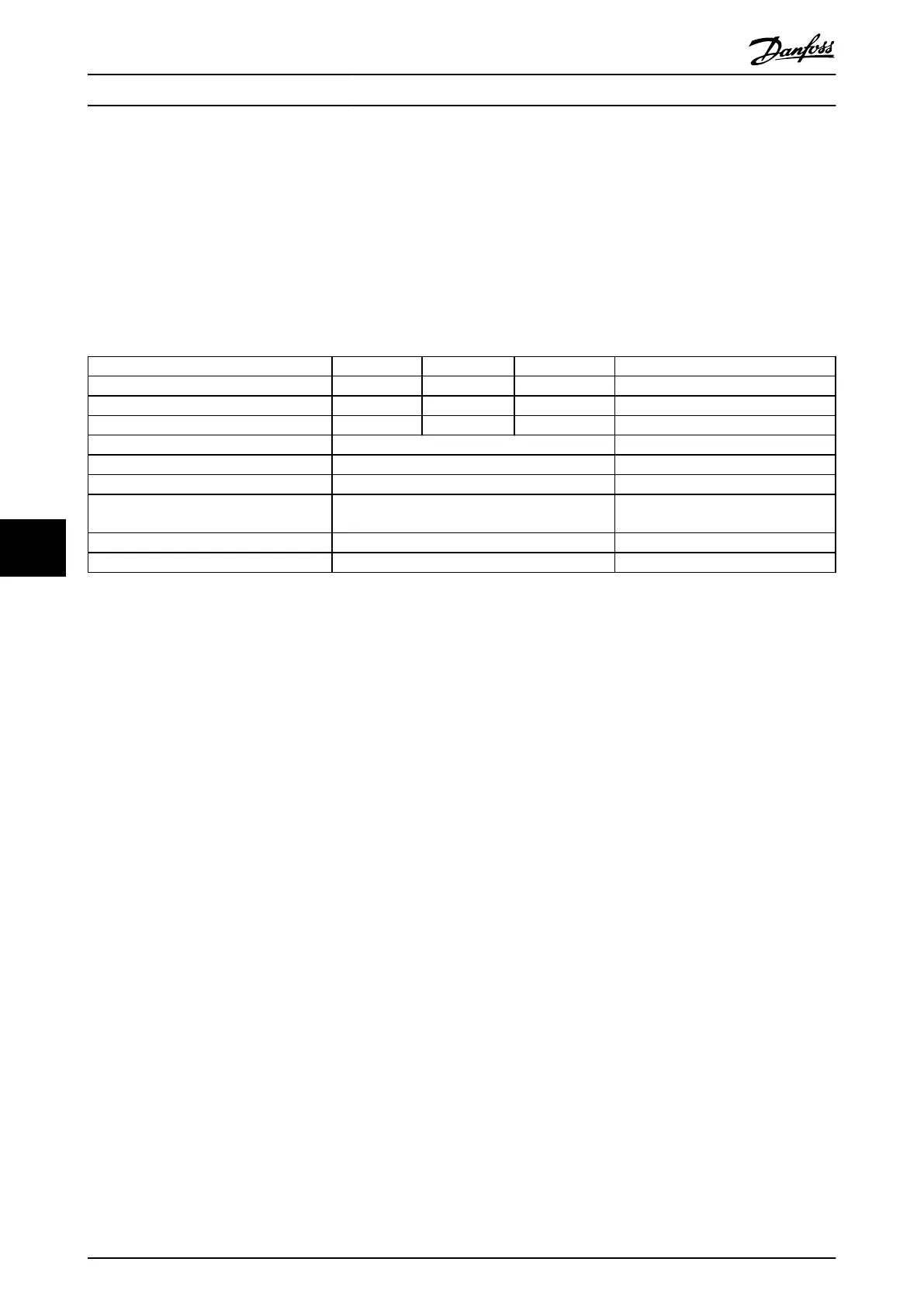

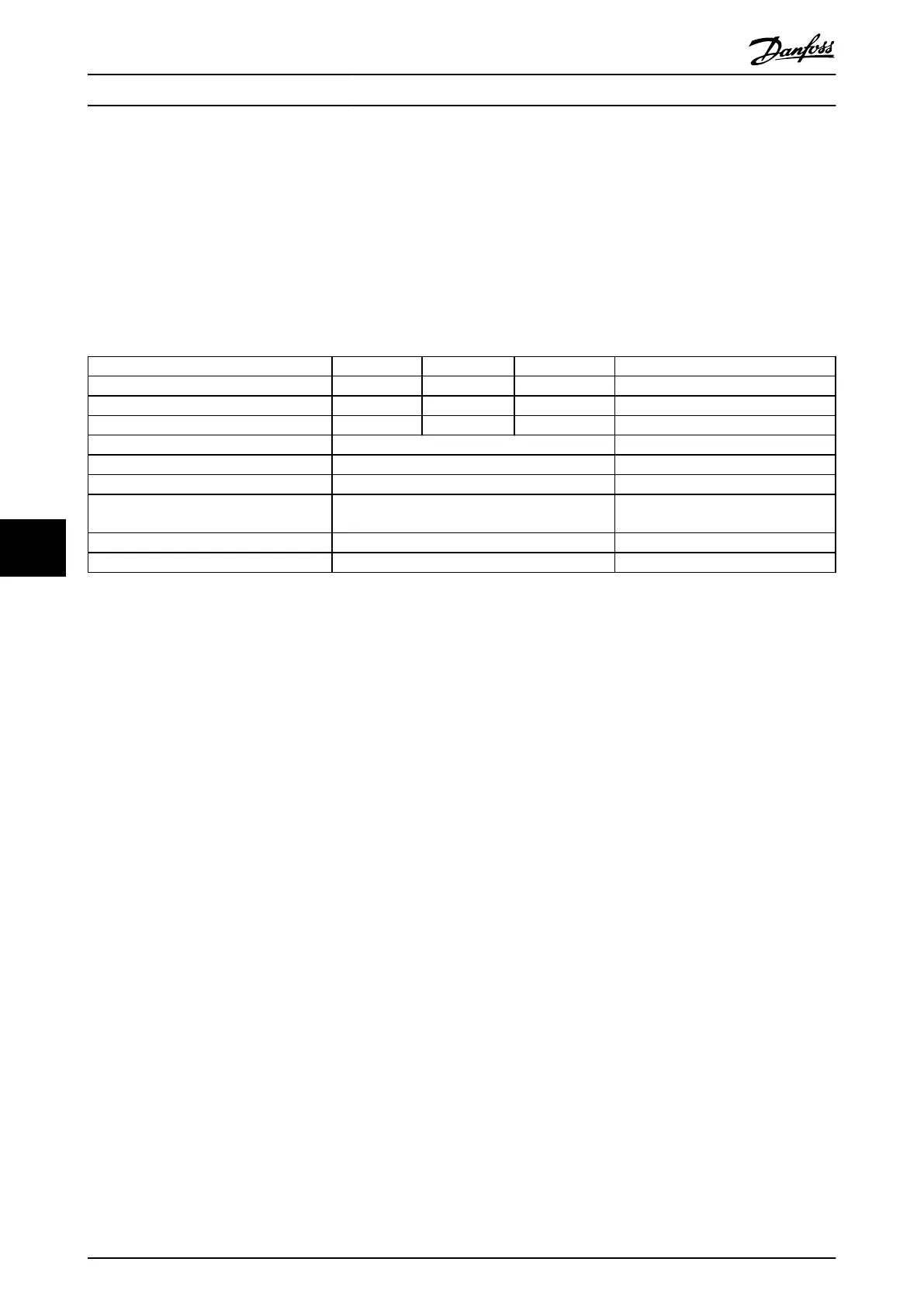

8.2 Filter Specifications

Frame size D E F

Voltage [V] 380-480 380-480 380-480

Current, RMS [A] 120 210 330 Nominal value

Peak Current [A] 340 595 935 Amplitude value of the current

RMS overload [%] No Overload 60 s in 10 min

Response time [ms] <0.5

Settling time - reactive current control [ms] <40

Settling time - harmonic current control

(filtering) [ms]

<20

Overshoot - reactive current control [%] <20

Overshoot - harmonic current control [%] <10

Table 8.4 Power Ranges (LHD with AF)

General Specifications VLT Automation Low Harmonic Drive Operating Instructions

146 MG34O202 - VLT

®

is a registered Danfoss trademark

88

Loading...

Loading...