90

80

70

60

50

40

30

20

10

0

0 0.5 4.9 13 27.3 45.9 66 89.3 115.7 147

(%)

(Pa)

Pressure Increase

Drive Derating

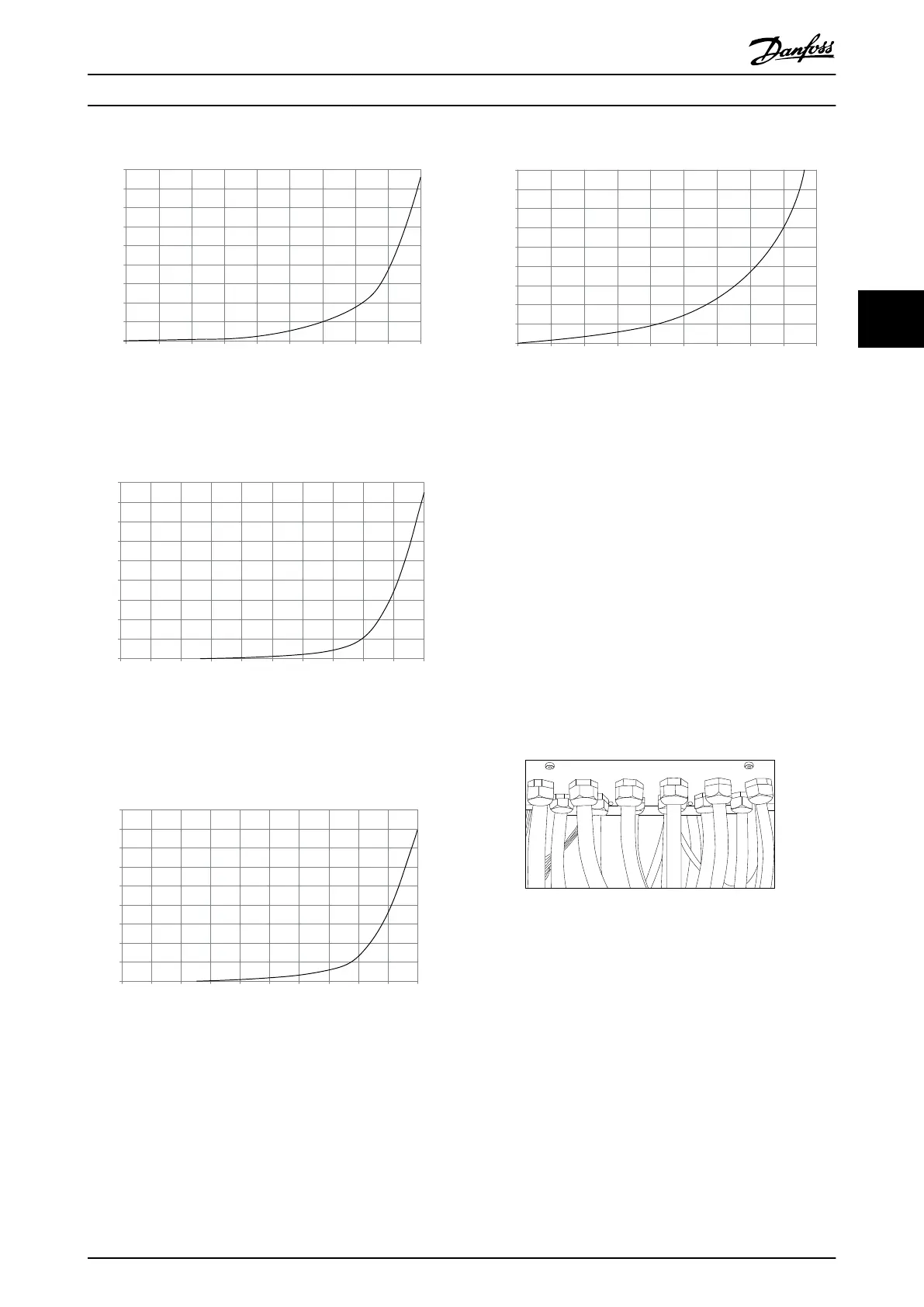

130BB007.10

Illustration 4.14 D frame Derating vs. Pressure Change

Drive air flow: 450 cfm (765 m

3

/h)

90

80

70

60

50

40

30

20

10

0

(%)

Drive Derating

0 0 0.1 3.6 9.8 21.5 43.4 76 237.5 278.9

(Pa)

Pressure Change

130BB010.10

147.1

Illustration 4.15 E frame Derating vs. Pressure Change (Small

Fan), P315

Drive air flow: 650 cfm (1105 m

3

/h)

90

80

70

60

50

40

30

20

10

0

(%)

Drive Derating

0 0.2 0.6 2.2 5.8 11.4 18.1 30.8 152.8 210.8

(Pa)

Pressure Change

130BB011.10

69.5

Illustration 4.16 E frame Derating vs. Pressure Change (Large

Fan) P355-P450

Drive air flow: 850 cfm (1445 m

3

/h)

90

80

70

60

50

40

30

20

10

0

(%)

Drive Derating

0 25 50 75 100 125 150 175 225

130BB190.10

200

Pressure Change

Illustration 4.17 F frame Derating vs. Pressure Change

Drive air flow: 580 cfm (985 m

3

/h)

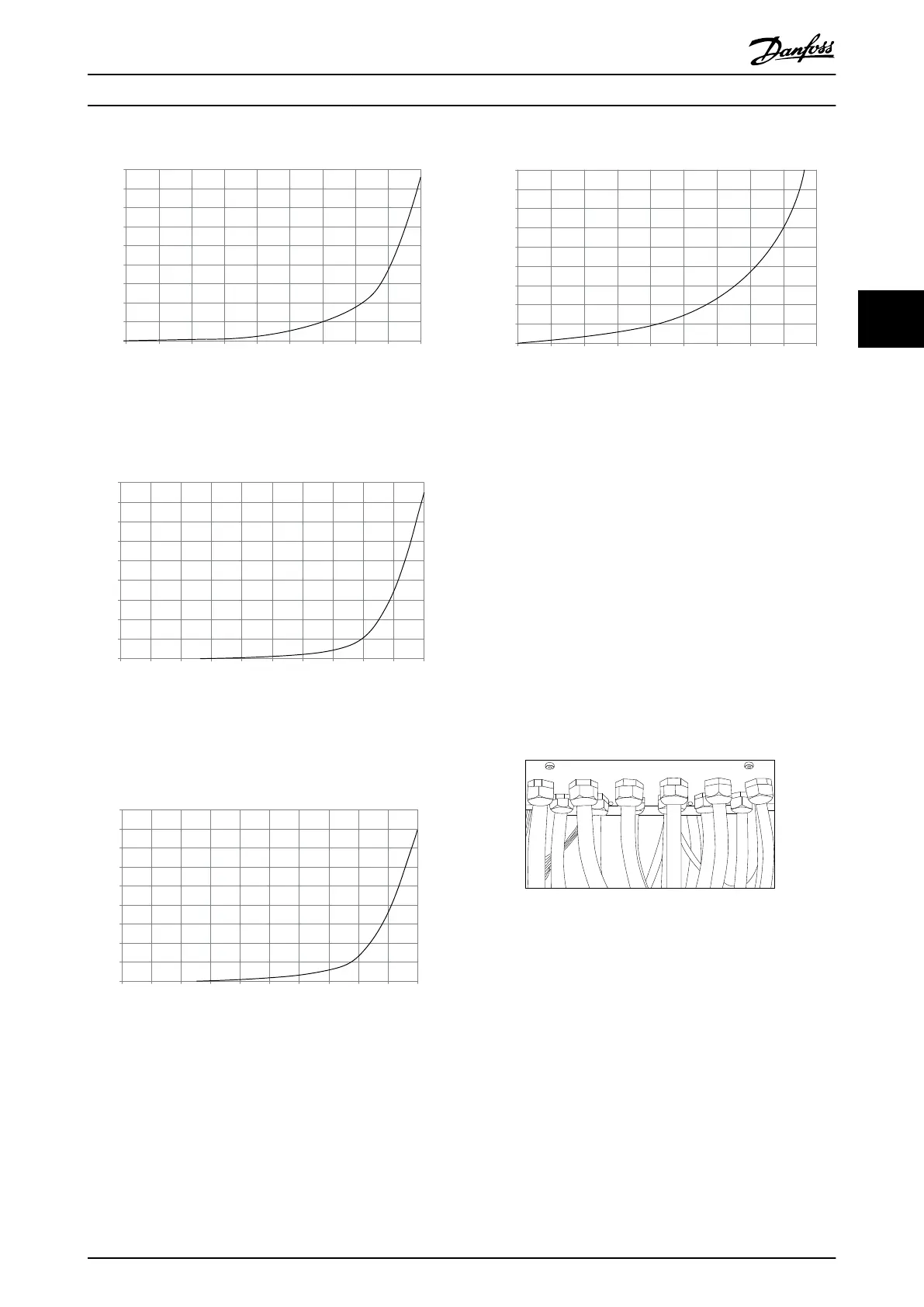

4.3.7

Gland/Conduit Entry - IP21 (NEMA 1)

and IP54 (NEMA12)

Cables are connected through the gland plate from the

bottom. Remove the plate and plan where to place the

entry for the glands or conduits. Prepare holes in the

marked area on the drawing.

NOTE

The gland plate must be fitted to the frequency converter

to ensure the specified protection degree, as well as

ensuring proper cooling of the unit. If the gland plate is

not mounted, the frequency converter may trip on Alarm

69, Pwr. Card Temp

Illustration 4.18 Example of proper installation of the gland

plate.

How to Install VLT Automation Low Harmonic Drive Operating Instructions

MG34O202 - VLT

®

is a registered Danfoss trademark 29

4 4

Loading...

Loading...