WARNING

HIGH VOLTAGE

Drives contain high voltage when connected to AC mains

input, DC supply, or load sharing. Failure to perform

installation, start-up, and maintenance by qualied

personnel can result in death or serious injury.

•

Only qualied personnel must perform instal-

lation, start-up, and maintenance.

•

Before performing any service or repair work,

use an appropriate voltage measuring device to

make sure that there is no remaining voltage on

the drive.

Troubleshooting

•

Remove the power from the drive and check

motor phase V.

ALARM 32, Motor phase W missing

Motor phase W between the drive and the motor is

missing.

WARNING

HIGH VOLTAGE

Drives contain high voltage when connected to AC mains

input, DC supply, or load sharing. Failure to perform

installation, start-up, and maintenance by qualied

personnel can result in death or serious injury.

•

Only qualied personnel must perform instal-

lation, start-up, and maintenance.

•

Before performing any service or repair work,

use an appropriate voltage measuring device to

make sure that there is no remaining voltage on

the drive.

Troubleshooting

•

Remove the power from the drive and check

motor phase W.

ALARM 33, Inrush fault

Too many power-ups have occurred within a short time

period.

Troubleshooting

•

Let the unit cool to operating temperature.

•

Check potential DC-link fault to ground.

WARNING/ALARM 34, Fieldbus communication fault

The eldbus on the communication option card is not

working.

WARNING/ALARM 35, Option fault

An option alarm is received. The alarm is option-specic.

The most likely cause is a power-up or a communication

fault.

WARNING/ALARM 36, Mains failure

This warning/alarm is only active if the supply voltage to

the drive is lost and parameter 14-10 Mains Failure is not

set to [0] No function.

Troubleshooting

•

Check the fuses to the drive and mains supply to

the unit.

ALARM 37, Phase imbalance

There is a current imbalance between the power units.

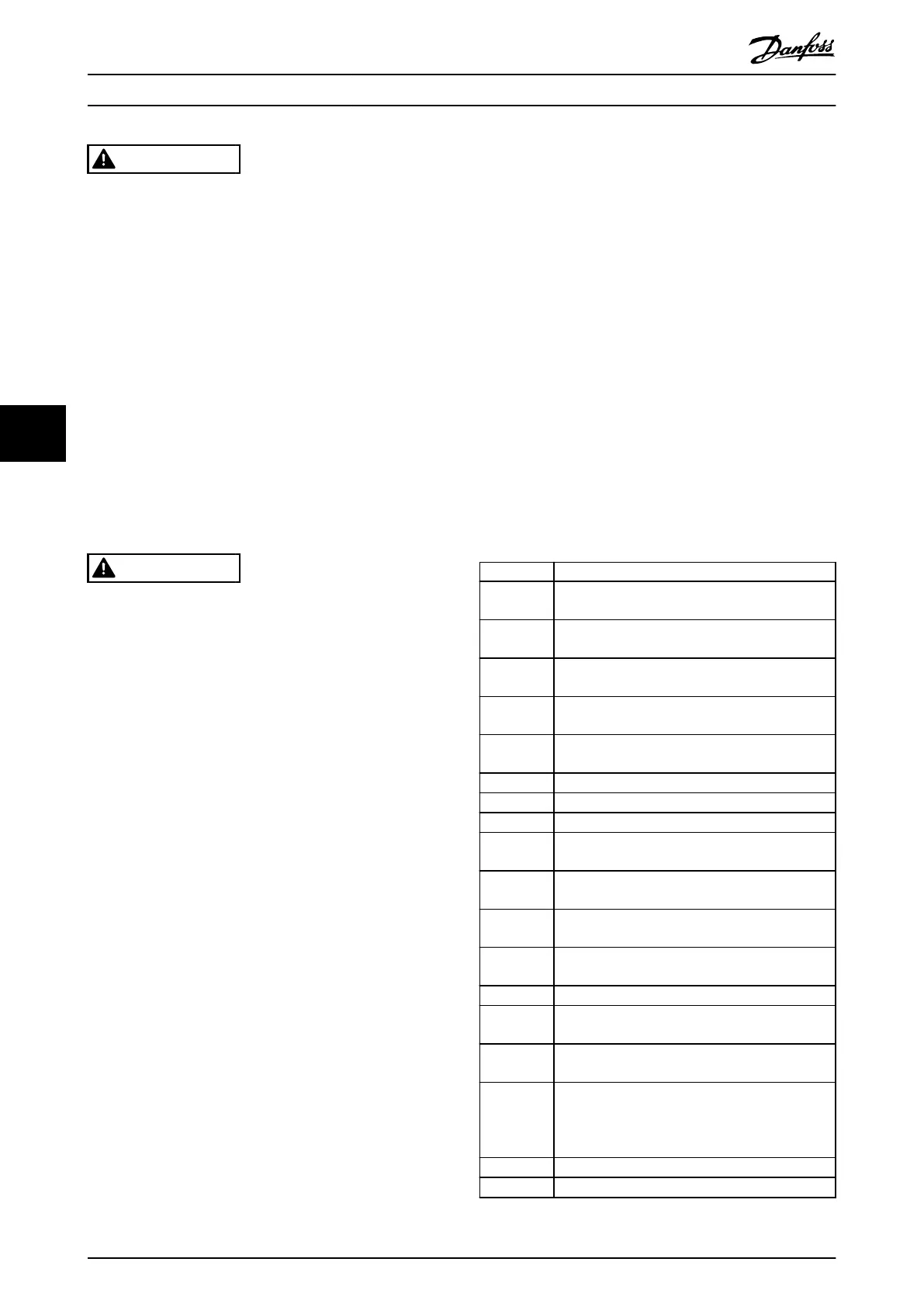

ALARM 38, Internal fault

When an internal fault occurs, a code number dened in

Table 6.4 is shown.

Troubleshooting

•

Cycle power.

•

Check that the option is properly installed.

•

Check for loose or missing wiring.

It may be necessary to contact the Danfoss supplier or

service department. Note the code number for further

troubleshooting directions.

Number Text

0 The serial port cannot be initialized. Contact the

Danfoss supplier or Danfoss service department.

256–258 The power EEPROM data is defective or too old.

Replace the power card.

512–519 Internal fault. Contact the Danfoss supplier or

Danfoss service department.

783 Parameter value outside of minimum/maximum

limits.

1024–1284 Internal fault. Contact the Danfoss supplier or

Danfoss service department.

1299 The option software in slot A is too old.

1300 The option software in slot B is too old.

1302 The option software in slot C1 is too old.

1315 The option software in slot A is not supported/

allowed.

1316 The option software in slot B is not supported/

allowed.

1318 The option software in slot C1 is not supported/

allowed.

1379–2819 Internal fault. Contact the Danfoss supplier or

Danfoss service department.

1792 Hardware reset of digital signal processor.

1793 Motor-derived parameters not transferred correctly

to the digital signal processor.

1794 Power data not transferred correctly at power-up

to the digital signal processor.

1795 The digital signal processor has received too many

unknown SPI telegrams. This situation can occur

due to poor EMC protection or improper

grounding.

1796 RAM copy error.

2561 Replace the control card.

Troubleshooting VLT® AutomationDrive FC 361

186 Danfoss A/S © 03/2019 All rights reserved. MG06J202

6

6

Loading...

Loading...