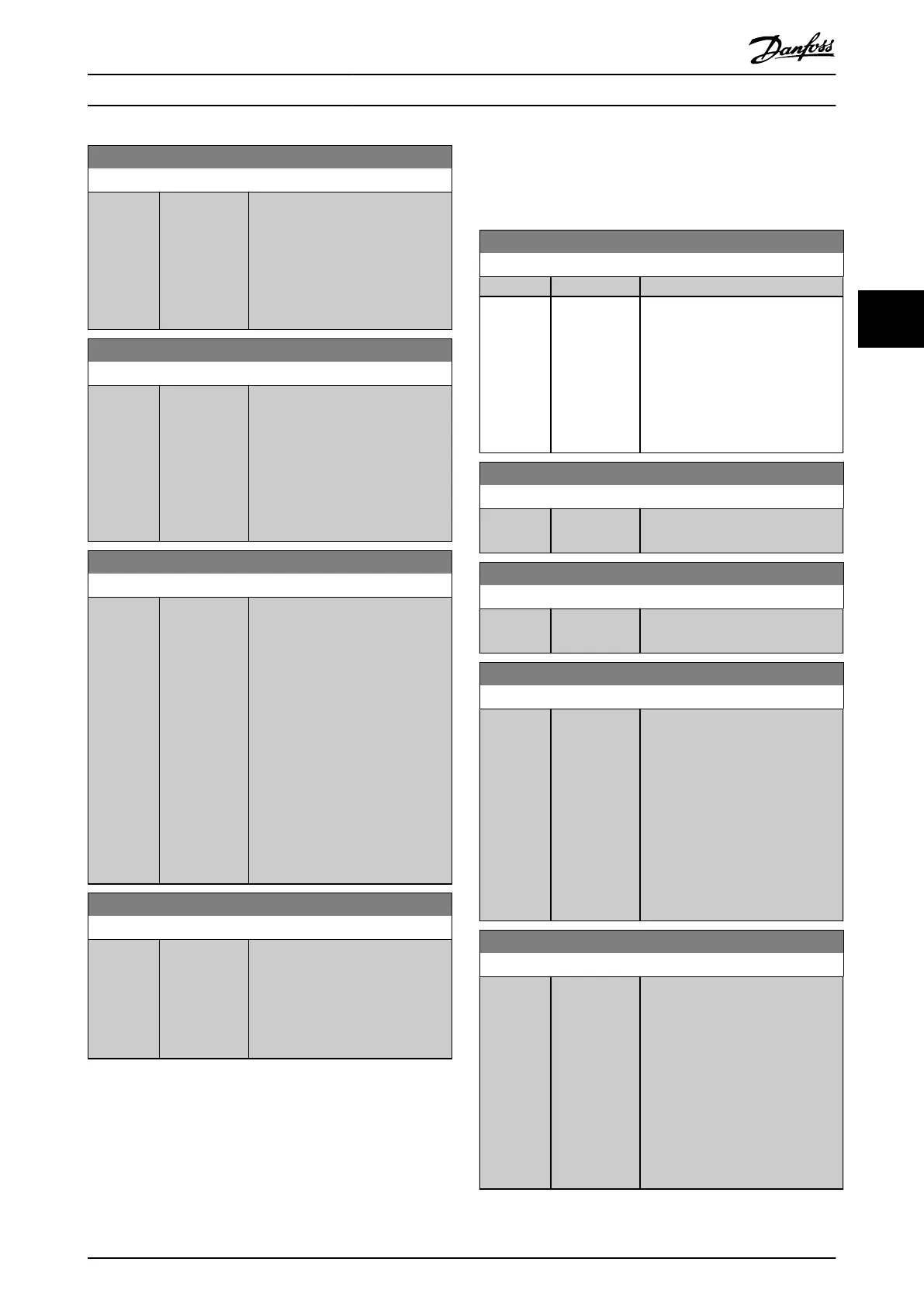

7-35 Process PID Dierentiation Time

Range: Function:

0 s* [0 - 10 s] Enter the PID dierentiation time.

The dierentiator does not react to

a constant error, but provides a

gain only when the error changes.

The shorter the PID dierentiation

time, the stronger the gain from

the dierentiator.

7-36 Process PID Di. Gain Limit

Range: Function:

5* [1 - 50] Enter a limit for the dierentiator

gain. If there is no limit, the dier-

entiator gain increases when there

are fast changes. To obtain a pure

dierentiator gain at slow changes

and a constant dierentiator gain

where fast changes occur, limit the

dierentiator gain.

7-38 Process PID Feed Forward Factor

Range: Function:

0 %* [0 - 200 %] Enter the PID feed forward factor.

The factor sends a constant fraction

of the reference signal to bypass

the PID control, so the PID control

only aects the remaining fraction

of the control signal. Any change to

this parameter aects the motor

speed. When the feed forward

factor is activated, it provides less

overshoot and high dynamics when

changing the setpoint.

Parameter 7-38 Process PID Feed

Forward Factor is active when

parameter 1-00 Conguration Mode

is set to [3] Process.

7-39 On Reference Bandwidth

Range: Function:

5 %* [0 - 200 %] Enter the on-reference bandwidth.

When the PID control error (the

dierence between the reference

and the feedback) is less than the

value of this parameter, the on-

reference status bit is 1.

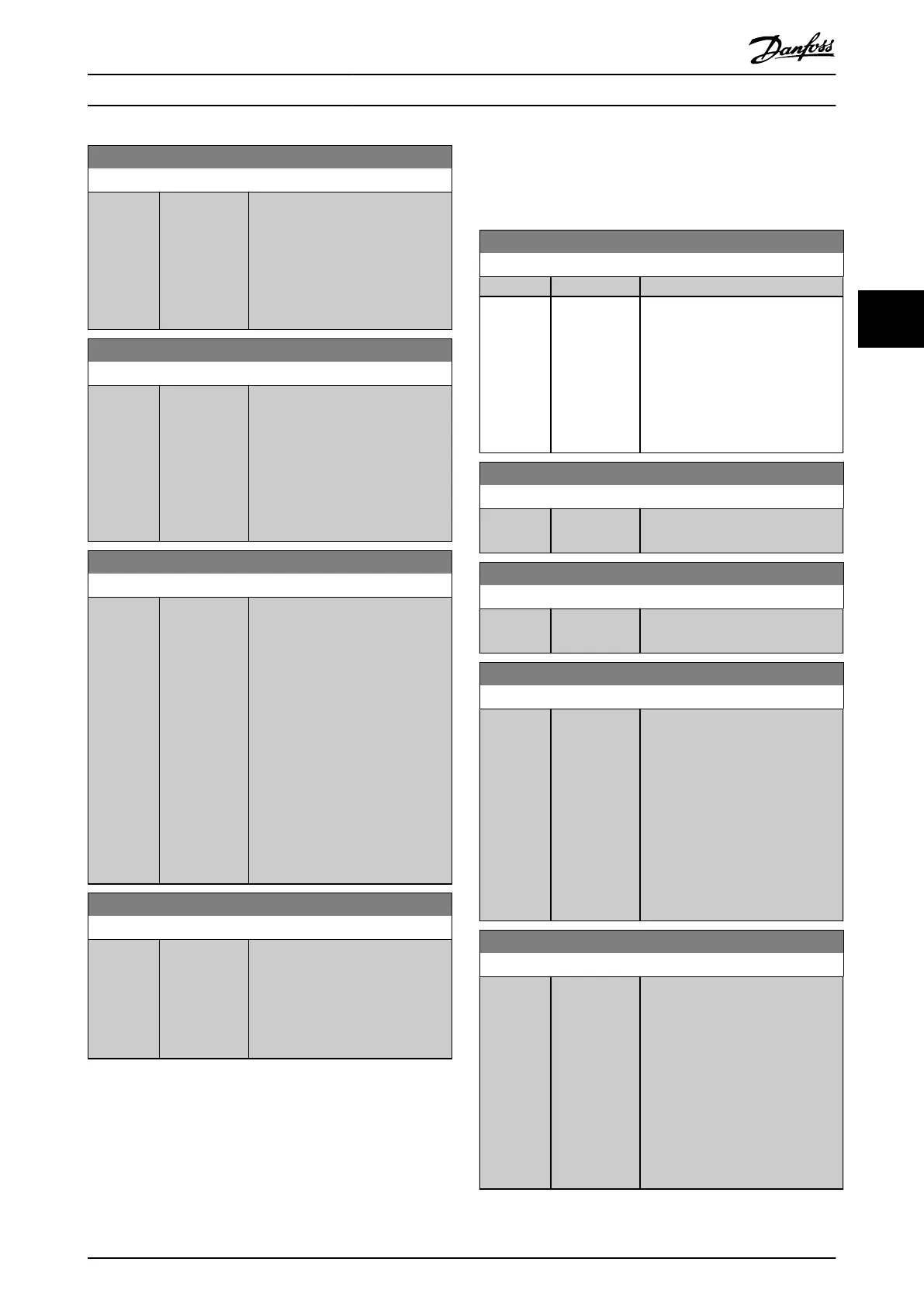

4.8.4 7-4* Advanced Process PID Ctrl.

This parameter group is only used if parameter 1-00 Cong-

uration Mode is set to [7] Extended PID speed CL.

7-40 Process PID I-part Reset

Option: Function:

[0] * No

[1] Yes Select [1] Yes to reset the I-part of

the process PID controller. The

selection automatically returns to

[0] No. Resetting the I-part makes it

possible to start from a well-

dened point after changing

something in the process, for

example changing a textile roll.

7-41 Process PID Output Neg. Clamp

Range: Function:

-100 %* [ -100 - par.

7-42 %]

Enter a negative limit for the

process PID controller output.

7-42 Process PID Output Pos. Clamp

Range: Function:

100 %* [ par. 7-41 -

100 %]

Enter a positive limit for the process

PID controller output.

7-43 Process PID Gain Scale at Min. Ref.

Range: Function:

100 %* [0 - 100 %] Enter a scaling percentage to apply

to the process PID output when

operating at the minimum

reference. The scaling percentage is

adjusted linearly between the scale

at minimum reference

(parameter 7-43 Process PID Gain

Scale at Min. Ref.) and the scale at

maximum reference

(parameter 7-44 Process PID Gain

Scale at Max. Ref.).

7-44 Process PID Gain Scale at Max. Ref.

Range: Function:

100 %* [0 - 100 %] Enter a scaling percentage to apply

to the process PID output when

operating at the maximum

reference. The scaling percentage is

adjusted linearly between the scale

at minimum reference

(parameter 7-43 Process PID Gain

Scale at Min. Ref.) and the scale at

maximum reference

(parameter 7-44 Process PID Gain

Scale at Max. Ref.).

Parameter Descriptions Programming Guide

MG06J202 Danfoss A/S © 03/2019 All rights reserved. 91

4 4

Loading...

Loading...