3. Electrical Installation

3.1. How to Connect

3.1.1. Electrical Installation in General

NB!

All cabling must comply with national and local regulations on cable cross-sections

and ambient temperature. Copper conductors required, (60-75° C) recommended.

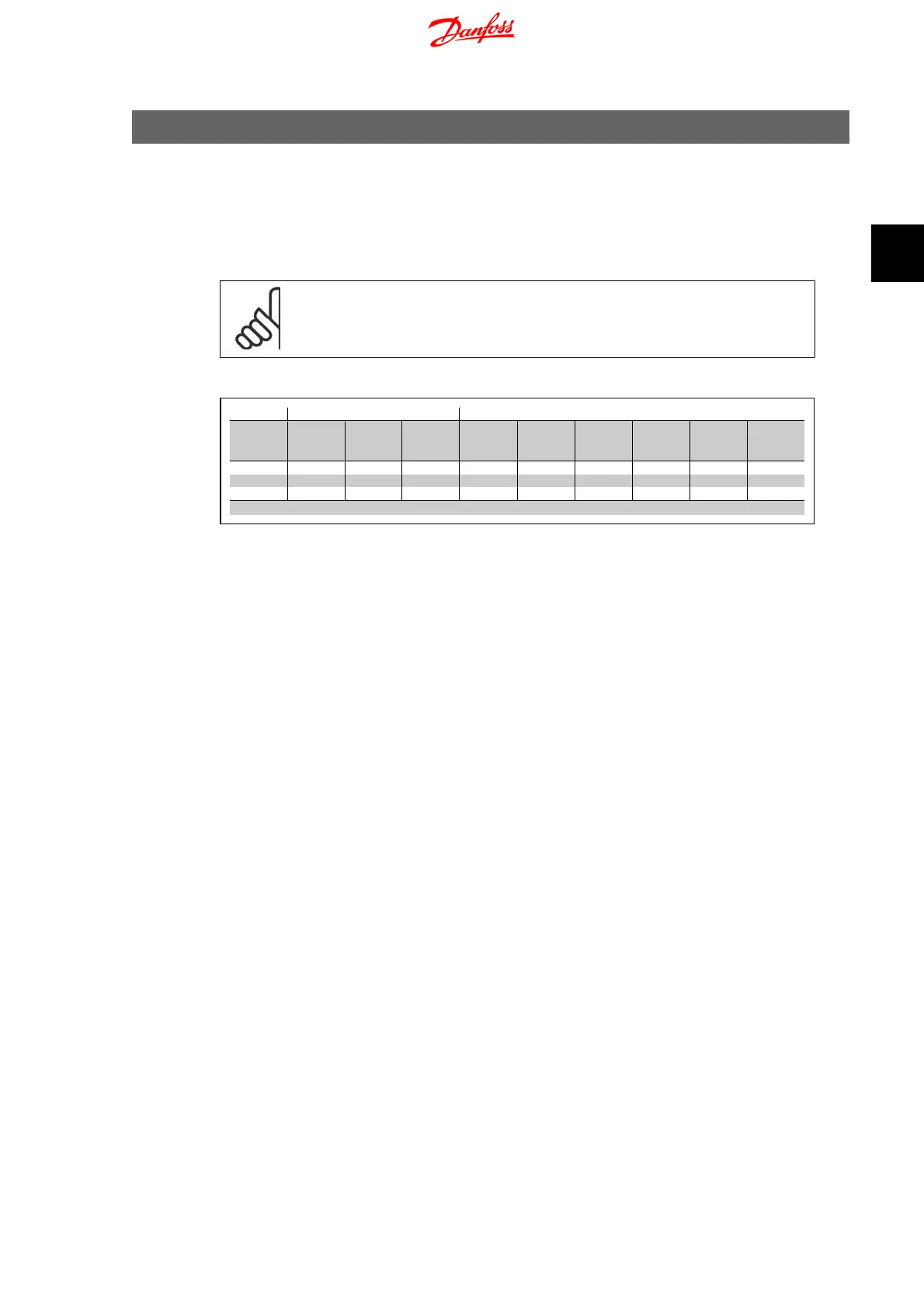

Details of terminal tightening torques.

Power (kW) Torque (Nm)

Frame

1 x

200-240 V

3 x

200-240 V

3 x

380-480 V

Line Motor

DC con-

nection/

Brake

1)

Control

Terminals

Earth Relay

M1 0.18 - 0.75 0.25 - 0.75 0.37 - 0.75 1.4 0.7 - 0.15 3 0.5

M2 1.5 1.5 1.5 - 2.2 1.4 0.7 - 0.15 3 0.5

M3 2.2 2.2 - 3.7 3.0 - 7.5 1.4 0.7 - 0.15 3 0.5

1)

Spade connectors

Table 3.1: Tightening of terminals.

3.1.2. Fuses

Branch circuit protection:

In order to protect the installation against electrical and fire hazard, all branch circuits in an in-

stallation, switch gear, machines etc., must be short-circuited and overcurrent protected according

to national/international regulations.

Short circuit protection:

Danfoss recommends using the fuses mentioned in the following tables to protect service per-

sonnel or other equipment in case of an internal failure in the unit or short-circuit on DC-link. The

frequency converter provides full short circuit protection in case of a short-circuit on the motor or

brake output.

Overcurrent protection:

Provide overload protection to avoid overheating of the cables in the installation. Overcurrent

protection must always be carried out according to national regulations. Fuses must be designed

for protection in a circuit capable of supplying a maximum of 100,000 A

rms

(symmetrical), 480 V

maximum.

NonUL compliance:

If UL/cUL is not to be complied with, Danfoss recommends using the fuses mentioned in table

1.3, which will ensure compliance with EN50178:

In case of malfunction, not following the fuse recommendation may result in damage to the fre-

quency converter.

VLT Micro Drive FC 51 Operating Instructions 3. Electrical Installation

MG.02.A2.02 - VLT

®

is a registered Danfoss trademark

9

3

Loading...

Loading...