WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors,

which can remain charged even when the frequency

converter is not powered. High voltage can be present

even when the warning LED indicator lights are o.

Failure to wait the specied time after power has been

removed before performing service or repair work can

result in death or serious injury.

•

Stop the motor.

•

Disconnect AC mains and remote DC-link power

supplies, including battery back-ups, UPS, and

DC-link connections to other frequency

converters.

•

Disconnect or lock PM motor.

•

Wait for the capacitors to discharge fully. The

minimum duration of waiting time is specied

in Table 2.1.

•

Before performing any service or repair work,

use an appropriate voltage measuring device to

make sure that the capacitors are fully

discharged.

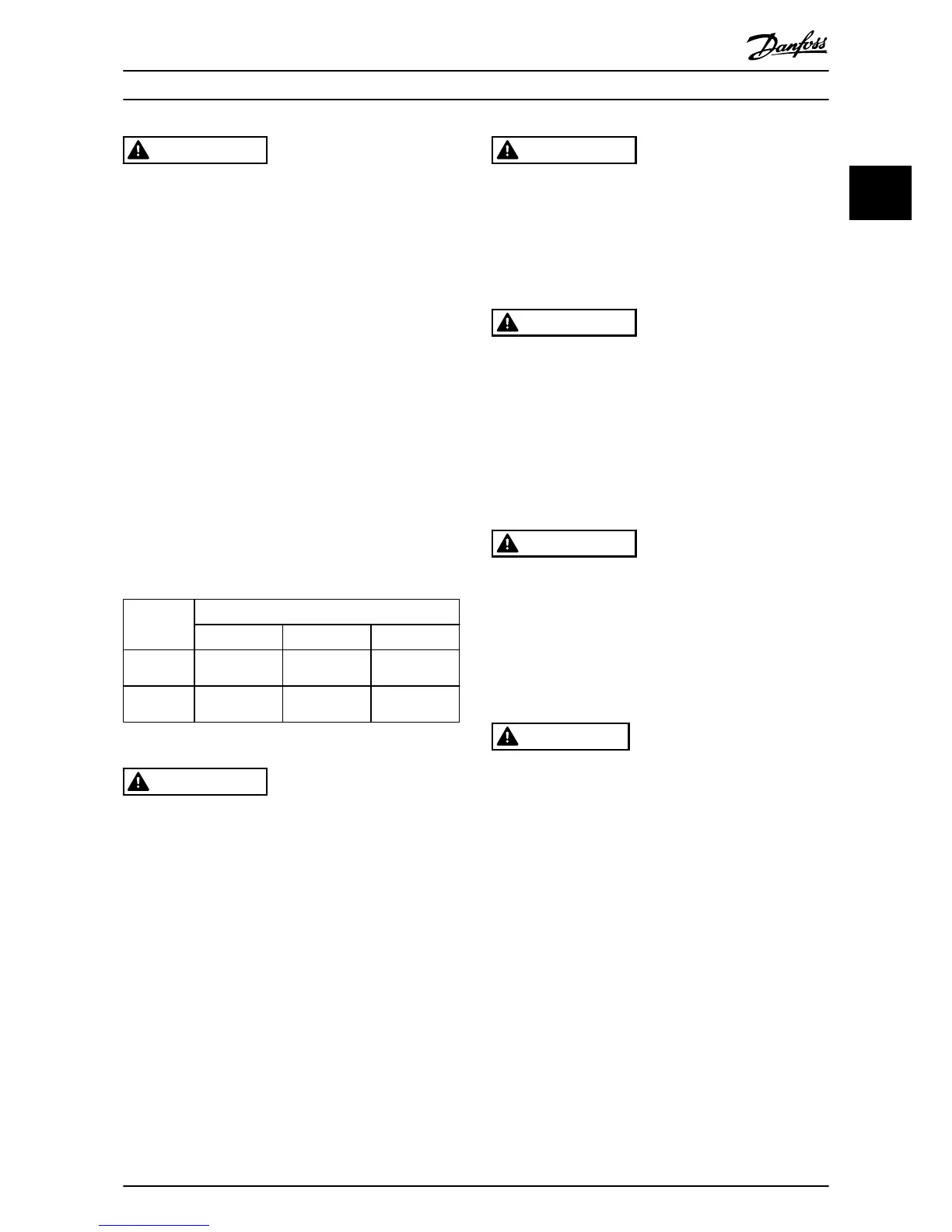

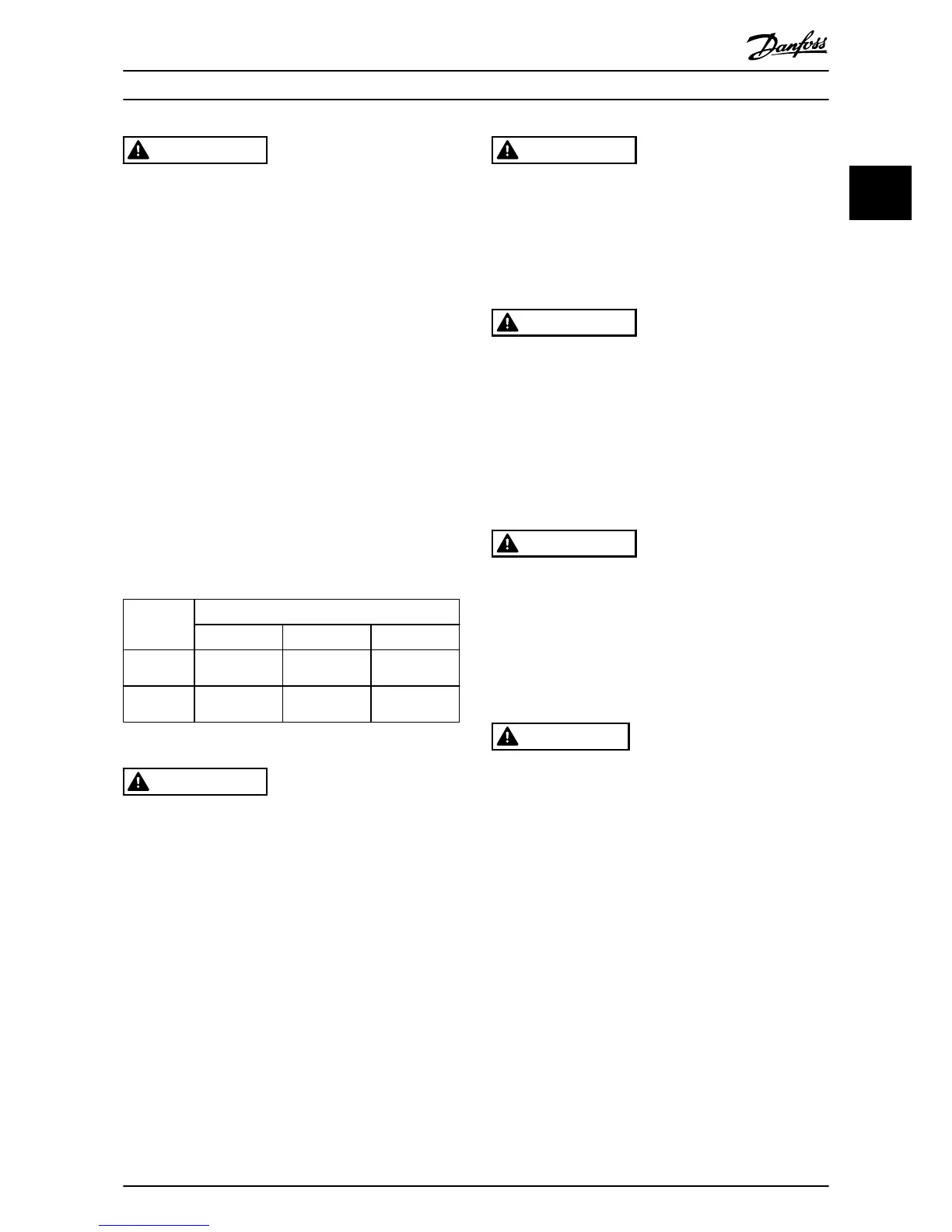

Voltage Minimum waiting time/power range

20 minutes 30 minutes 40 minutes

380–500 V 90–200 kW

(125–275 hp)

– 250–800 kW

(350–1075 hp)

525–690 37–315 kW (50–

450 hp)

– 355–1200 kW

(500–1600 hp)

Table 2.1 Discharge Time

WARNING

UNEXPECTED ELECTRICAL SHOCK HAZARD

Parts of the VLT

®

Plus Panel can still be powered when

the frequency converter is switched o. Solely removing

the fuses, or switching the mains disconnect do not

switch the VLT

®

Plus Panel o. A contactor is not a safe

disconnection method, when any manipulation in the

panel or at the frequency converter is performed.

•

Always follow the local technical and safety

rules.

•

Do not use contactors for safe disconnect.

•

Always use a voltage meter to make sure that

any parts are voltage-free before touching

them.

•

Access to the VLT

®

Plus Panels for any handling

and operation is allowed for

qualied personnel

only.

WARNING

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground

frequency converter properly can result in death or

serious injury.

•

Ensure the correct grounding of the equipment

by a certied electrical installer.

WARNING

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment

can result in death or serious injury.

•

Ensure that only trained and qualied personnel

perform installation, start-up, and maintenance.

•

Ensure that electrical work conforms to national

and local electrical codes.

•

Follow the procedures in this manual.

WARNING

UNINTENDED MOTOR ROTATION

WINDMILLING

Unintended rotation of permanent magnet motors

creates voltage and can charge the unit, resulting in

death, serious injury, or equipment damage.

•

Ensure that permanent magnet motors are

blocked to prevent unintended rotation.

CAUTION

INTERNAL FAILURE HAZARD

An internal failure in the frequency converter can result

in serious injury, when the frequency converter is not

properly closed.

•

Ensure that all safety covers are in place and

securely fastened before applying power.

To run STO, additional wiring for the frequency converter is

required. Refer to VLT

®

Frequency Converters Safe Torque O

Operating Instructions for further information.

Safety Installation Guide

MG13B102 Danfoss A/S © 09/2015 All rights reserved. 9

2 2

Loading...

Loading...