5 Specications

5.1 Technical Design Considerations

WARNING

FUNCTIONAL-SAFETY COMPLIANT USE

The VLT

®

Plus Panel is a product in accordance with the

Low Voltage Directive 2006/95/EG, but does not provide

safety-related control functionality in accordance with

Machine Safety Directive 2006/42/EG. CE declaration is

therefore related to EMC (2004/108/EG) and LV Directive.

Failure to take the necessary safety-related control

measures can result in death or serious injury.

•

The panel operator has to ensure the proper

use of the product, even when Safe Torque O

(STO) functionality is used, for example for

ATEX-conform motor thermal protection. In this

case, the safety function is part of the approved

motor thermal protection, using the function as

appropriate energy cut-o.

•

Any other use of the safety functions is in sole

responsibility of the end user, including certi-

cation, documentation, and so on.

•

Customized variants can dier and are not

subject to the panel congurator product

description.

NOTICE

The notication of maximum possible cross-section and

number of wires is shown in drawings for each main

component, where mains and motor cables can be

directly connected. The drawings are provided with the

panel.

Electrical specications

Mains supply 400 V, 500 V, or 690 V, PEN, 3-phase, 50 Hz, IT or

TN, as selected.

Maximum

short circuit

capabilities

I

CW

= 35 kA on infeed terminals of the panel, see

Table 5.2.

Assembly

rated current

I

nA

In accordance with the relevant frequency

converter current rating.

NOTICE

For VLT

®

AutomationDrive FC 302, NO

(normal overload) values are used for the

design. Due to the 80% design rule of EN

61439-2, design is adjusted for the HO

(high overload) use. Details are provided

per power rating in the relevant

documents.

RDF RDF is specied to 1 for all power circuitry as

only 1 frequency converter is foreseen per panel/

infeed.

Cables/wires Cables/wires used according to DIN standards,

cross-section in mm

2

. Any specied power cable

can be used. Always consider local standards

must always be taken into considerations.

Energy

cabling

Energy cabling is done directly to the relevant

terminals of switchgear, frequency converter, or

lter.

Cable entry Bottom cable entry.

Wiring color

code

According to DIN EN 60204-1.

Table 5.1 Electrical Specications

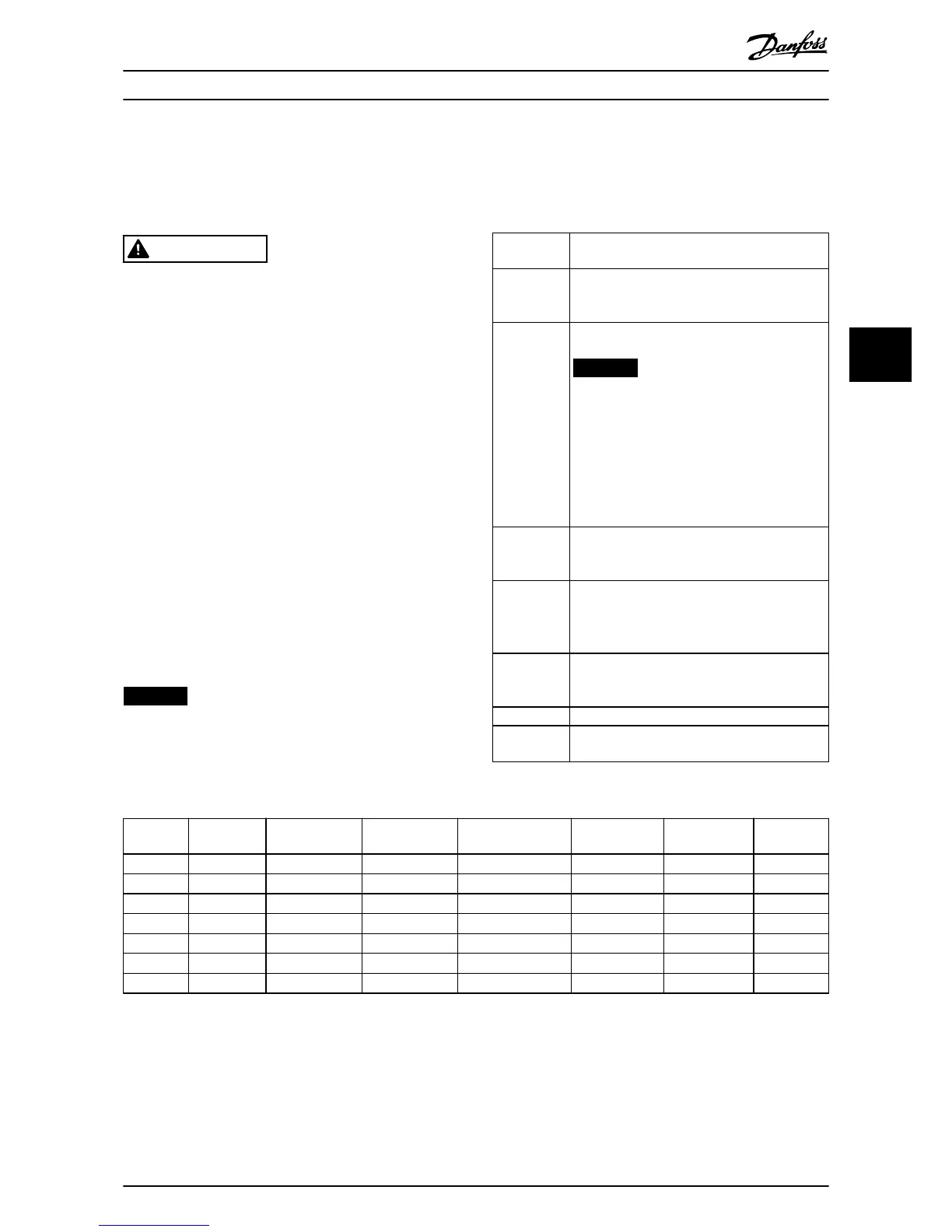

Power

[kW]

Fuse

1)

I

CW

(200 ms) I

C

Let through energy

(200 ms)

I

CC

for I

CW

@35

kA

I

2

t@35 kA PE [mm

2

]

90 kW 3NA7 140 2.2 kA 5.6 kA

945 kA

2

s

15 kA

400 kA

2

s

30x5

110 kW 3NA7 144 2.9 kA 7.4 kA

1673 kA

2

s

19.3 kA

780 kA

2

s

30x5

132 kW 3NA7 252 4 kA 10.2 kA

3238 kA

2

s

24.1 kA

1275 kA

2

s

30x10

160 kW 3NA7 260 5.1 kA 12.9 kA

5508 kA

2

s

29.5 kA

2150 kA

2

s

30x10

200 kW 3NA3 365 7.7 kA 19.5 kA

11409 kA

2

s

39.3 kA

2700 kA

2

s

30x10

250 kW 3NA3 365 7.7 kA 19.5 kA

11409 kA

2

s

39.3 kA

2700 kA

2

s

30x10

315 kW 3NA3 372 10.5 kA 26.8 kA

21848 kA

2

s

48.7 kA

5400 kA

2

s

30x10

Table 5.2 Short Circuit Withstand Capability According to DIN EN 61439

1) Siemens example; fuses with same characteristics from other suppliers can be used.

Specications Installation Guide

MG13B102 Danfoss A/S © 09/2015 All rights reserved. 29

5 5

Loading...

Loading...