3.4.15 Motor Insulation

For motor cable lengths ≤ the maximum cable length

listed in chapter 5.4 Cable Specications, the motor

insulation ratings in Table 3.28 are recommended. Peak

voltage can be up to twice the DC-link voltage, and 2.8

times the mains voltage, due to transmission line eects in

the motor cable. If a motor has lower insulation rating, use

a dU/dt or sine-wave lter.

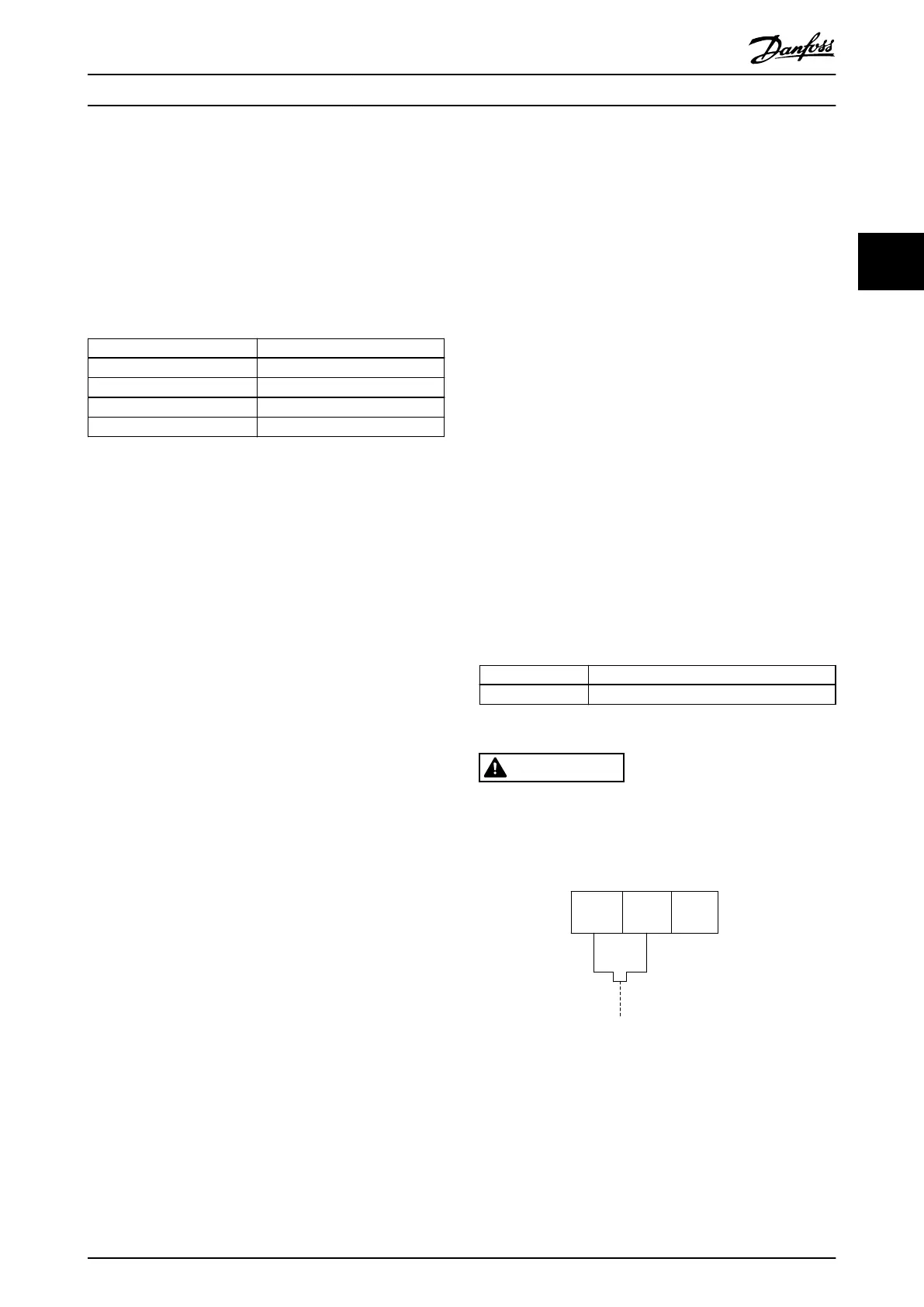

Nominal mains voltage [V] Motor insulation [V]

U

N

≤420

Standard U

LL

=1300

420<U

N

≤500 Reinforced U

LL

=1600

500<U

N

≤600 Reinforced U

LL

=1800

600<U

N

≤ 690 Reinforced U

LL

=2000

Table 3.28 Motor Insulation Ratings

3.4.16 Motor Bearing Currents

All motors installed with VLT

®

AutomationDrive FC 302

frequency converters with a power rating of 250 kW or

higher must have NDE (Non-Drive End) insulated bearings

installed to eliminate circulating bearing currents. To

minimize DE (Drive End) bearing and shaft currents, ensure

that the frequency converter, motor, driven machine, and

motor to the driven machine are grounded properly.

Standard mitigation strategies:

1. Use an insulated bearing.

2. Apply rigorous installation procedures.

2a Ensure that the motor and load motor

are aligned.

2b Strictly follow the EMC installation

guideline.

2c Reinforce the PE so the high frequency

impedance is lower in the PE than the

input power leads.

2d Provide a good high frequency

connection between the motor and the

frequency converter, for example by

using shielded cable which has a 360°

connection in the motor and the

frequency converter.

2e Make sure that the impedance from the

frequency converter to the building

ground is lower than the grounding

impedance of the machine.

2f Make a direct ground connection

between the motor and load motor.

3. Lower the IGBT switching frequency.

4.

Modify the inverter waveform, 60° AVM vs.

SFAVM.

5. Install a shaft grounding system or use an

isolating coupling.

6. Apply conductive lubrication.

7. Use minimum speed settings where possible.

8. Ensure that the mains voltage is balanced to

ground.

9. Use a dU/dt or sine-wave lter.

3.4.17 Brake Resistor Temperature Switch

•

Torque: 0.5–0.6 Nm (5 in-lb)

•

Screw size: M3

This input can be used to monitor the temperature of an

externally connected brake resistor. If the input between

104 and 106 is established, the frequency converter trips

on warning/alarm 27 Brake IGBT. If the connection is closed

between 104 and 105, the frequency converter trips on

warning/alarm 27 Brake IGBT.

Install a KLIXON switch that is normally closed. If this

function is not used, short circuit 106 and 104 together.

•

Normally closed: 104–106 (factory installed

jumper)

•

Normally open: 104–105

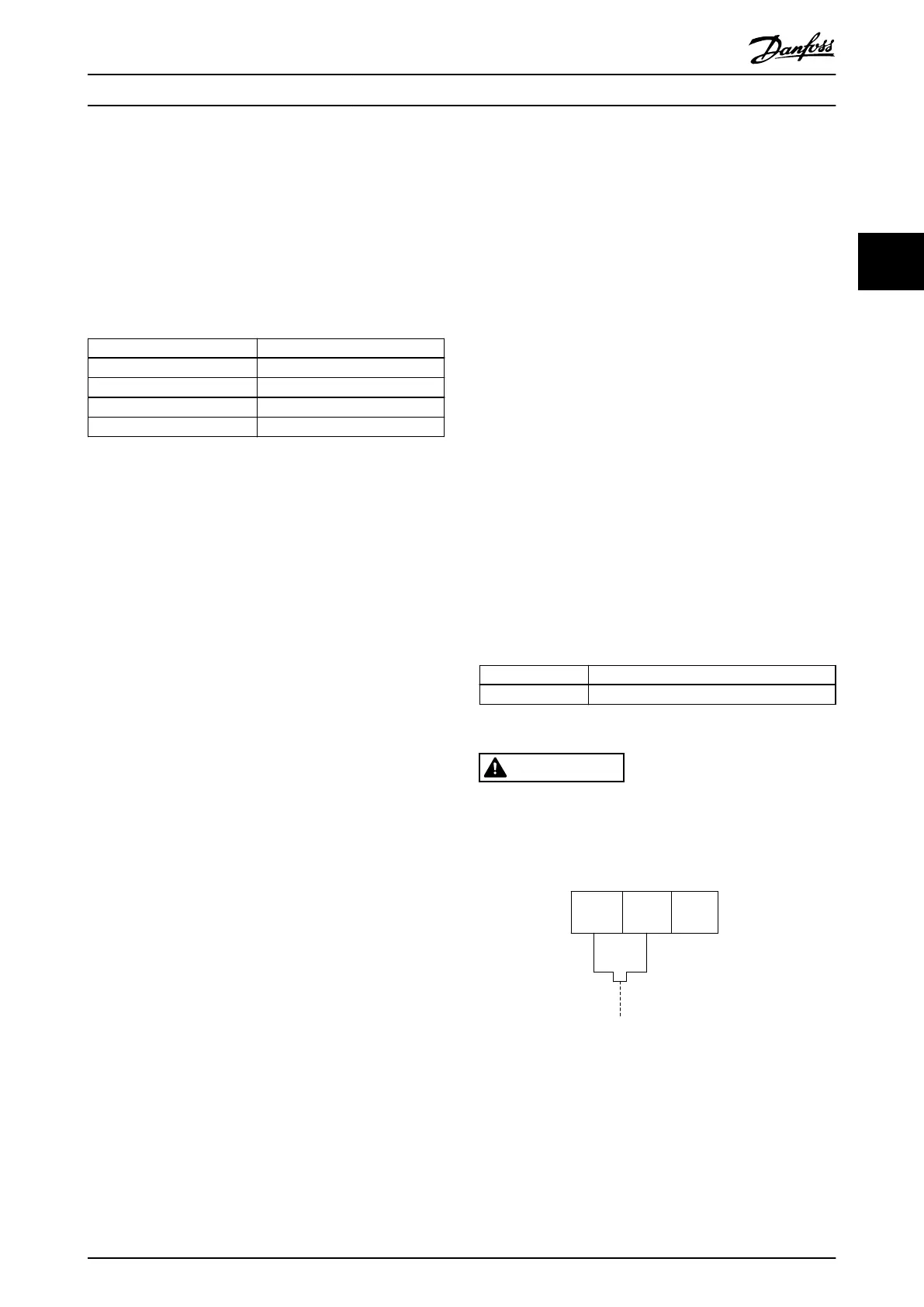

Terminal number Function

106, 104, 105 Brake resistor temperature switch.

Table 3.29 Brake Resistor Temperature Switch Terminals

CAUTION

MOTOR COASTING

If the temperature of the brake resistor gets too high

and the thermal switch drops out, the frequency

converter stops braking and the motor starts coasting.

175ZA877.10

106

NC

104

C

105

NO

Illustration 3.47 Brake Resistor Temperature Switch

How to Install Operating Instructions

MG34Q402 Danfoss A/S © 04/2016 All rights reserved. 51

3 3

Loading...

Loading...