The 1400–2000 kW (1875–2680 hp) 690 V frequency

converters are approved for CE only.

1.5 Disposal

Do not dispose of equipment containing

electrical components together with

domestic waste.

Collect it separately in accordance with

local and currently valid legislation.

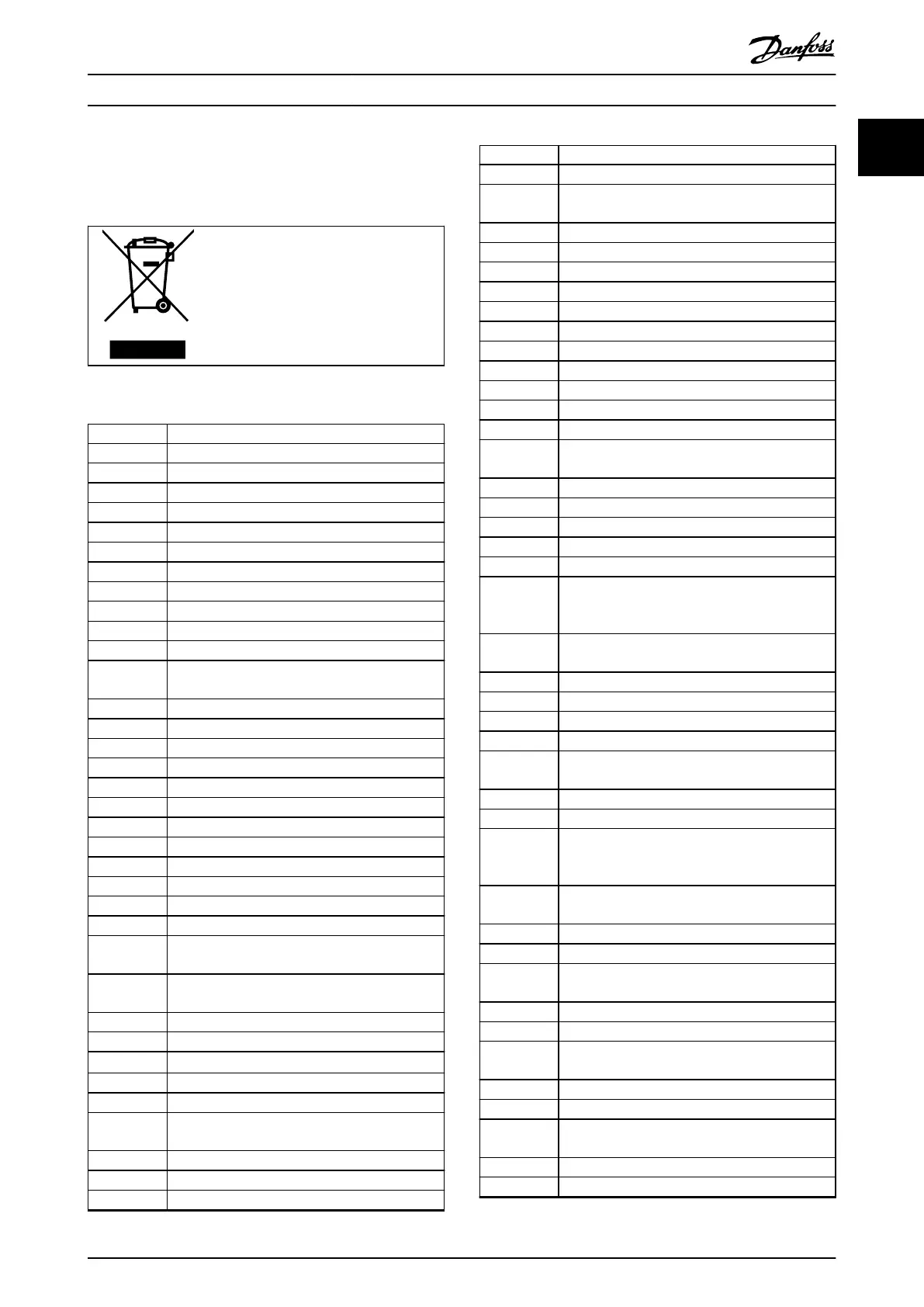

1.6 Abbreviations and Conventions

60° AVM 60° asynchronous vector modulation

A Ampere/AMP

AC Alternating current

AD Air discharge

AEO Automatic energy optimization

AI Analog input

AIC Ampere interrupting current

AMA Automatic motor adaptation

AWG American wire gauge

°C

Degrees celsius

CB Circuit breaker

CD Constant discharge

CDM Complete drive module: The frequency converter,

feeding section, and auxiliaries

CE European Conformity (European safety standards)

CM Common mode

CT Constant torque

DC Direct current

DI Digital input

DM Dierential mode

D-TYPE Drive dependent

EMC Electromagnetic compatibility

EMF Electromotive force

ETR Electronic thermal relay

f

JOG

Motor frequency when jog function is activated

f

M

Motor frequency

f

MAX

Maximum output frequency, the frequency

converter applies on its output

f

MIN

Minimum motor frequency from the frequency

converter

f

M,N

Nominal motor frequency

FC Frequency converter

Hiperface

®

Hiperface

®

is a registered trademark by Stegmann

HO High overload

hp Horse power

HTL HTL encoder (10–30 V) pulses - High-voltage

transistor logic

Hz Hertz

I

INV

Rated inverter output current

I

LIM

Current limit

I

M,N

Nominal motor current

I

VLT,MAX

Maximum output current

I

VLT,N

Rated output current supplied by the frequency

converter

kHz Kilohertz

LCP Local control panel

lsb Least signicant bit

m Meter

mA Milliampere

MCM Mille circular mil

MCT Motion control tool

mH Inductance in milli Henry

mm Millimeter

ms Millisecond

msb Most signicant bit

η

VLT

Eciency of the frequency converter dened as

ratio between power output and power input

nF Capacitance in nano Farad

NLCP Numerical local control panel

Nm Newton meter

NO Normal overload

n

s

Synchronous motor speed

Online/

Oine

Parameters

Changes to online parameters are activated

immediately after the data value is changed

P

br,cont.

Rated power of the brake resistor (average power

during continuous braking)

PCB Printed circuit board

PCD Process data

PDS Power drive system: a CDM and a motor

PELV Protective extra low voltage

P

m

Frequency converter nominal output power as

high overload (HO)

P

M,N

Nominal motor power

PM motor Permanent magnet motor

Process PID PID (proportional integrated dierential) regulator

that maintains the speed, pressure, temperature,

and so on

R

br,nom

Nominal resistor value that ensures a brake power

on the motor shaft of 150/160% for 1 minute

RCD Residual current device

Regen Regenerative terminals

R

min

Minimum permissible brake resistor value by

frequency converter

RMS Root mean square

RPM Revolutions per minute

R

rec

Recommended brake resistor resistance of

Danfoss brake resistors

s Second

SCCR Short circuit current rating

SFAVM Stator ux-oriented asynchronous vector

modulation

STW Status word

SMPS Switch mode power supply

Introduction Operating Instructions

MG34Q402 Danfoss A/S © 04/2016 All rights reserved. 5

1 1

Loading...

Loading...