3.2 Mechanical Installation

3.2.1 Preparation for Installation

To ensure reliable and eective installation of the

frequency converter, make the following preparations:

•

Provide a suitable mounting arrangement. The

mounting arrangement depends on the design,

weight, and torque of the frequency converter.

•

To ensure that the space requirements are met,

examine the mechanical drawings.

•

Ensure that all wiring is done in accordance with

national regulations.

3.2.2 Tools Required

•

Drill with 10 mm or 12 mm bit.

•

Tape measure.

•

Wrench with relevant metric sockets (7–17 mm).

•

Extensions to wrench.

•

Sheet metal punch for conduits or cable glands in

IP21/NEMA 1 and IP54 units

•

Lifting bar to lift the unit (rod or tube maximum

Ø 25 mm (1 in), able to lift minimum 400 kg (880

lb).

•

Crane or other lifting aid to place the frequency

converter in position.

3.2.3 General Considerations

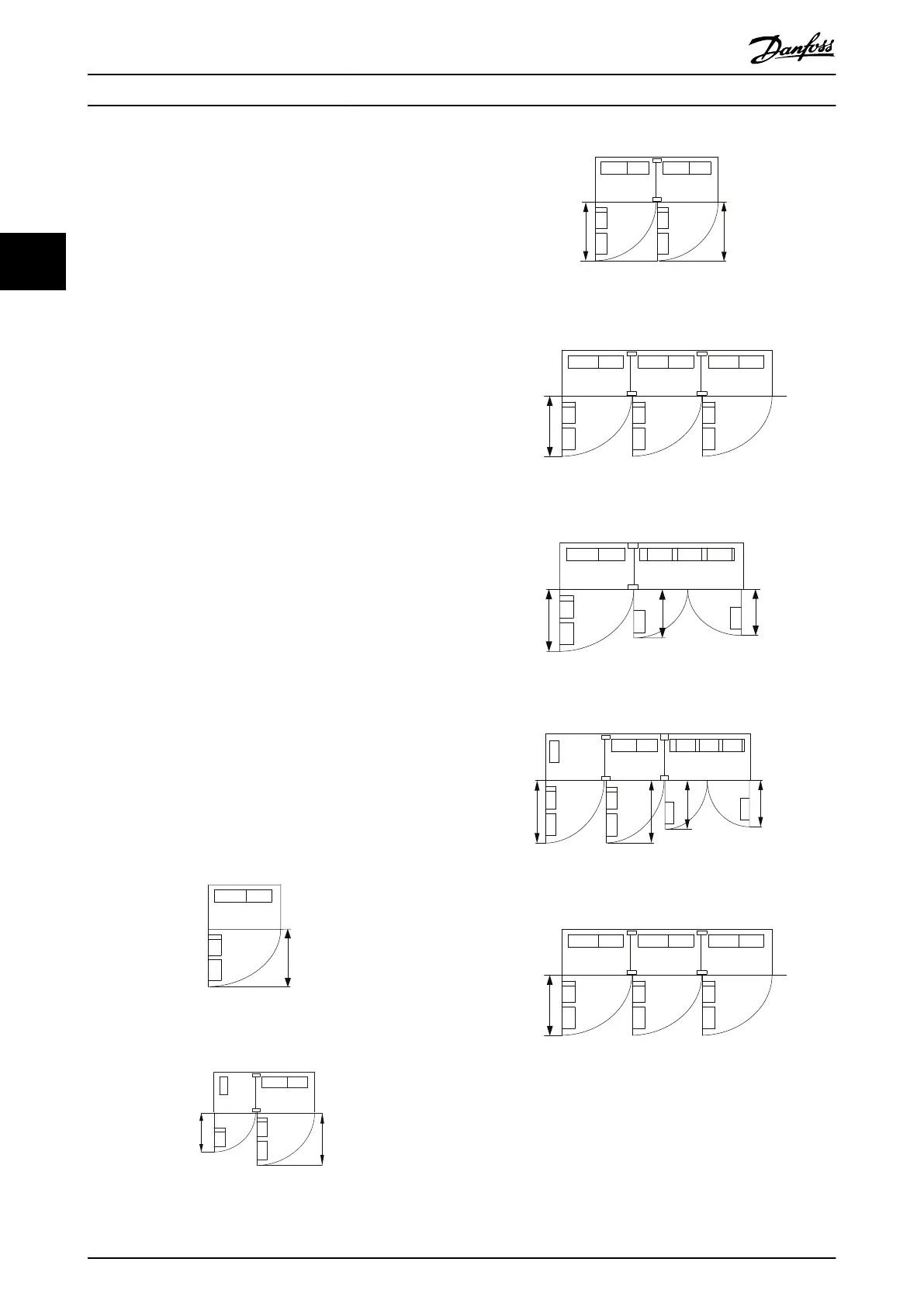

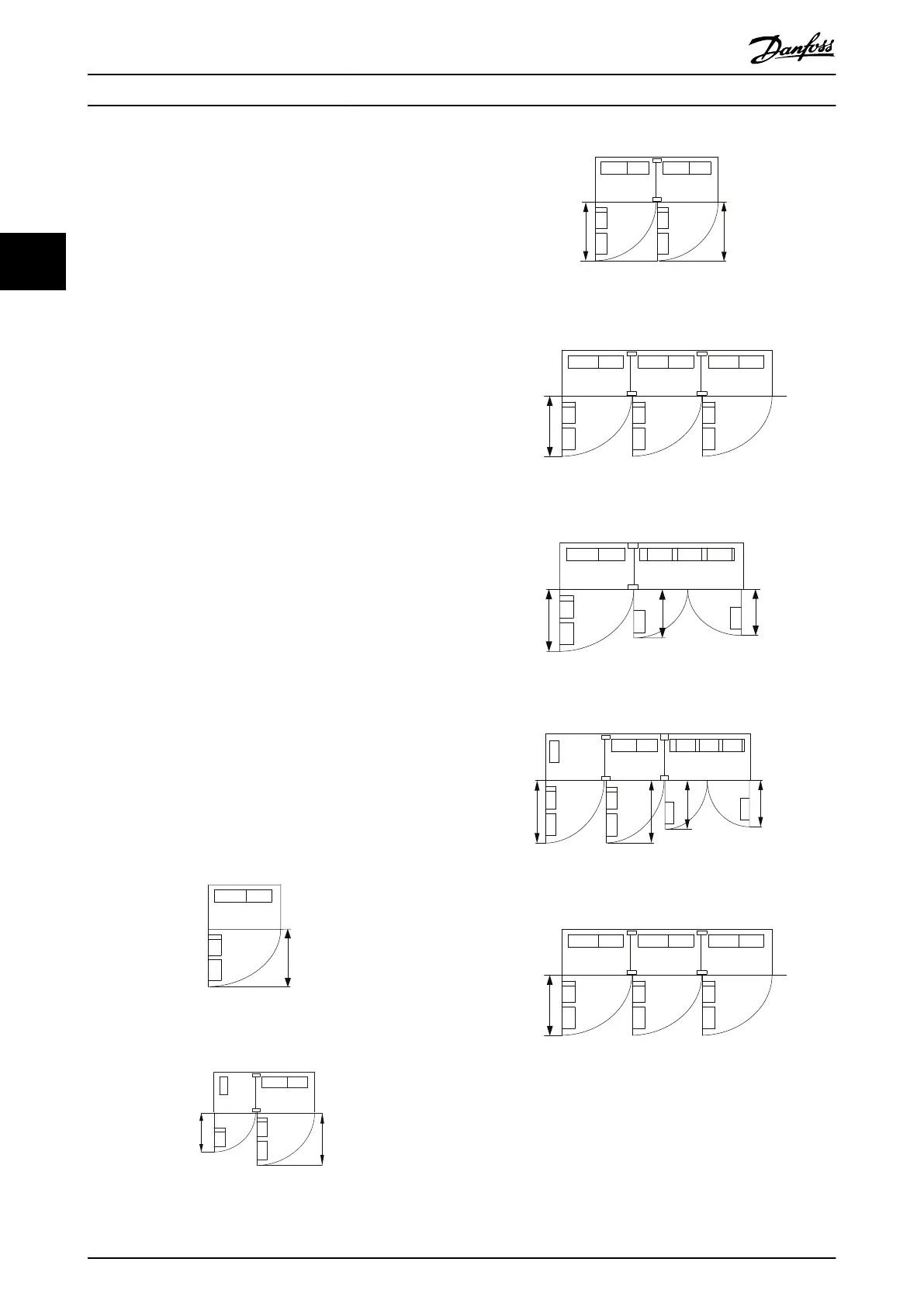

Space

To allow airow and cable access, ensure sucient space

above and below the frequency converter. In addition,

allow for enough space in front of the unit to open the

panel door, see Illustration 3.5 to Illustration 3.12.

Illustration 3.5 Space in Front of Enclosure Size F8

130BB003.13

776

(30.6)

578

(22.8)

Illustration 3.6 Space in Front of Enclosure Size F9

776

(30.6)

776

(30.6)

130BB574.10

Illustration 3.7 Space in Front of Enclosure Size F10

130BB575.10

776 (30.6)

(2x)

Illustration 3.8 Space in Front of Enclosure Size F11

130BB576.10

776

(30.6)

624

(24.6)

579

(22.8)

Illustration 3.9 Space in Front of Enclosure Size F12

130BB577.10

776

(30.6)

776

(30.6)

624

(24.6)

579

(22.8)

Illustration 3.10 Space in Front of Enclosure Size F13

130BB575.10

776 (30.6)

(2x)

Illustration 3.11 Space in Front of Enclosure Size F14

How to Install

VLT

®

AutomationDrive FC 302

18 Danfoss A/S © 04/2016 All rights reserved. MG34Q402

33

Loading...

Loading...