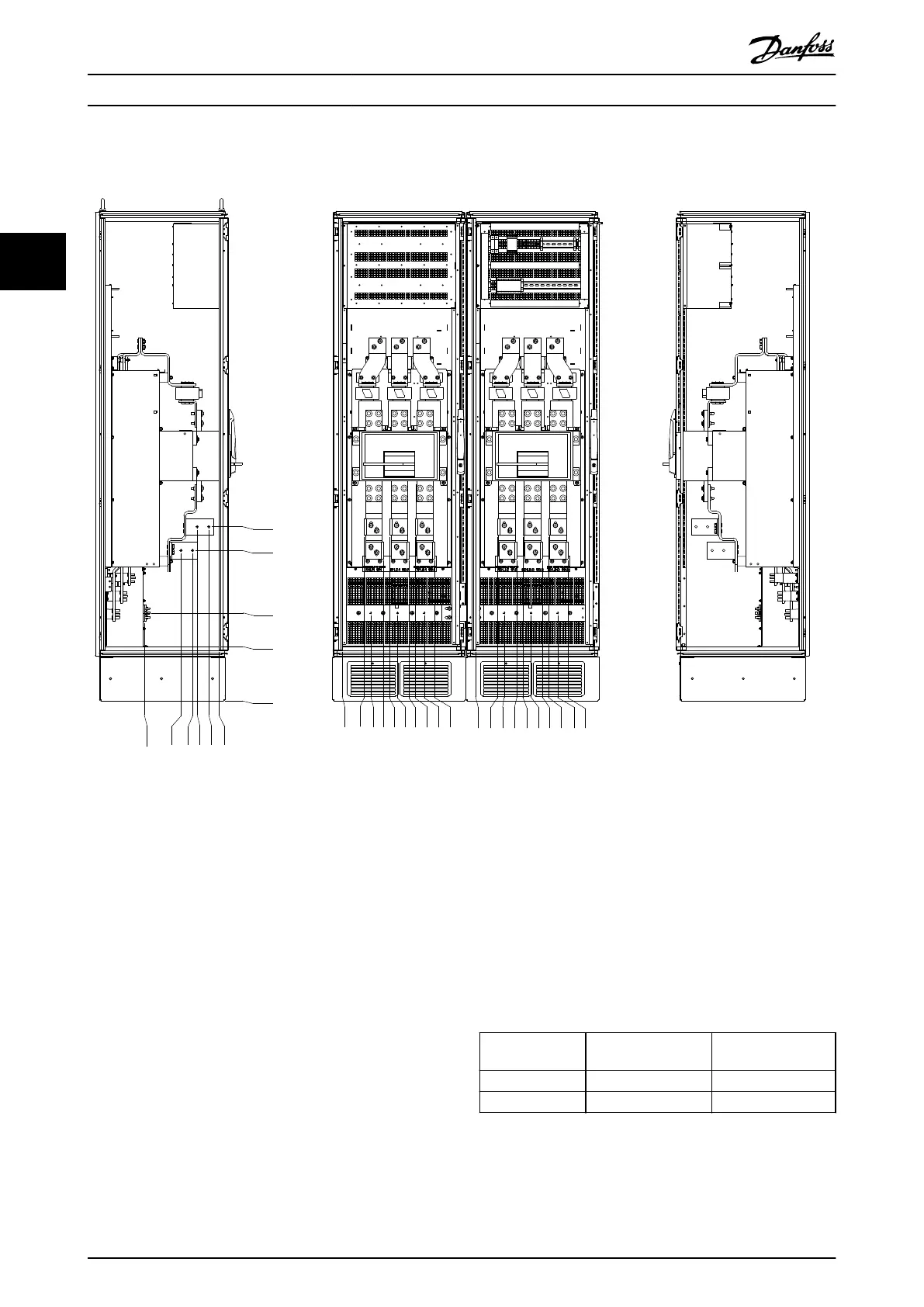

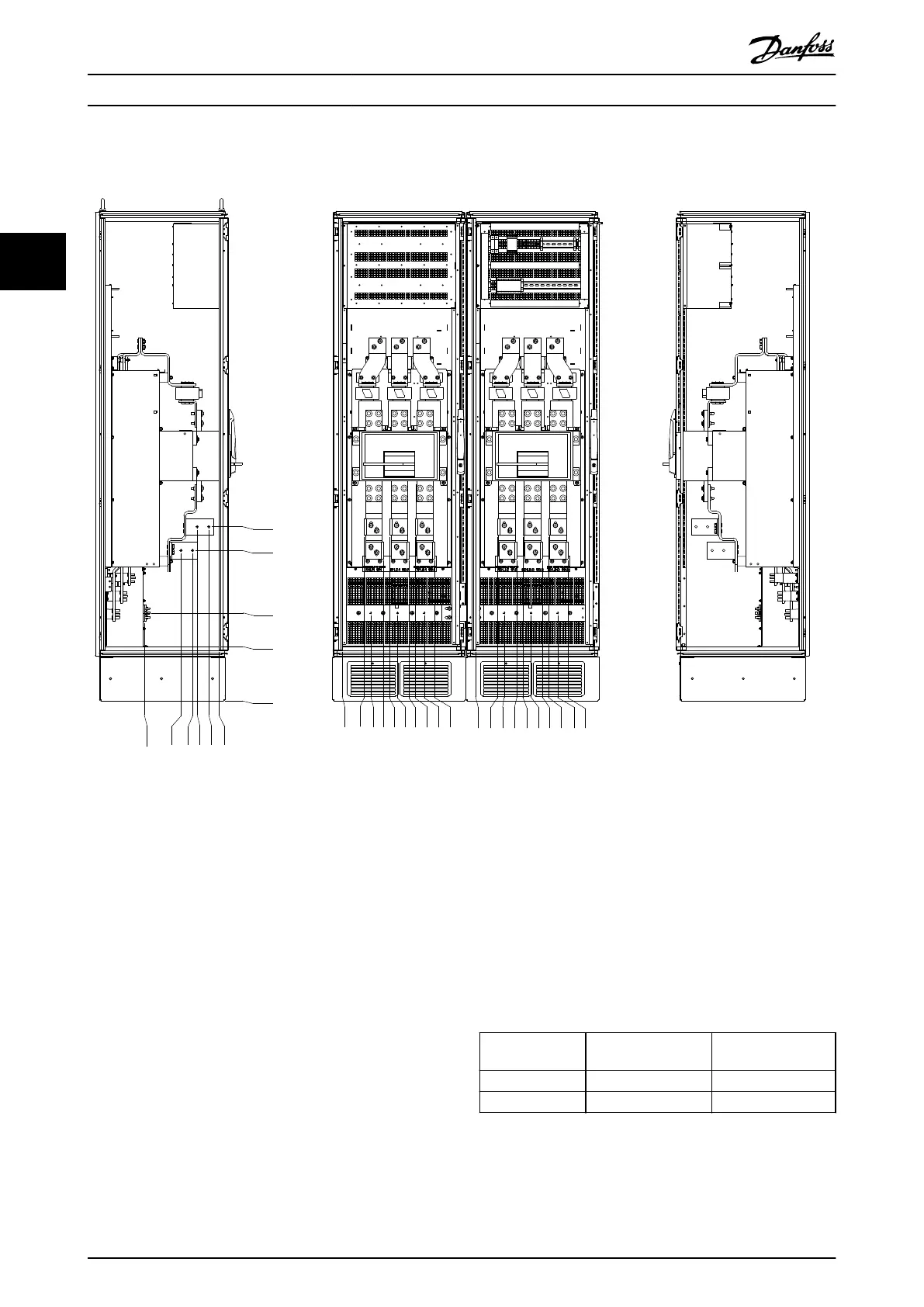

3.2.4.9 Options Cabinet, Enclosure Size F15

539.1

432.2

151.3

0.0

244.4

336.4

171.0

119.0

98.3

46.3

0.0

0.0

97.9

128.5

185.7

212.9

249.0

300.7

327.9

369.5

415.7

600.0

697.9

728.5

785.7

812.9

849.0

900.7

927.9

969.5

1015.7

130BE180.10

Illustration 3.21 Terminal Locations – Left, Front, and Right Views

3.2.5 Cooling and Airow

Cooling

Cooling can be achieved in dierent ways:

•

By using the cooling ducts at the top and bottom

of the unit.

•

By taking air in and out the back of the unit.

•

By combining the cooling methods.

Duct cooling

A dedicated option has been developed to optimize the

installation of frequency converters in Rittal TS8 enclosures

utilizing the frequency converter fan for forced air cooling

of the backchannel. The air out of the top of the enclosure

could be ducted outside a facility so the heat losses from

the backchannel are not dissipated within the control

room. Ducting the air outside the facility ultimately

reduces the air-conditioning requirements of the facility.

Back cooling

The backchannel air can also be ventilated in and out of

the back of a Rittal TS8 enclosure. The backchannel takes

cool air from outside the facility and returns warm air to

outside the facility, thus reducing air-conditioning

requirements.

Airow

Ensure sucient airow over the heat sink. The ow rate is

shown in Table 3.8.

Enclosure

protection

Door fans/Top fan

airow

Heat sink fans

IP21/NEMA 1

700 m

3

/h (412 cfm)

1)

985 m

3

/h (580 cfm)

1)

IP54/NEMA 12

525 m

3

/h (309 cfm)

1)

985 m

3

/h (580 cfm)

1)

Table 3.8 Heat Sink Air Flow

1) Airow per fan. Enclosure sizes F contain multiple fans.

How to Install

VLT

®

AutomationDrive FC 302

28 Danfoss A/S © 04/2016 All rights reserved. MG34Q402

33

Loading...

Loading...