3.4.18 Control Cable Routing

Tie all control wires down to the designated control cable

routing. Remember to connect the shields in a proper way

to ensure optimum electrical immunity.

Fieldbus connection

Connections are made to the relevant options on the

control card. For details, see the relevant eldbus

instruction. Place the cable in the provided path inside the

frequency converter and tie it down with other control

wires.

Installation of 24 V DC external supply

•

Torque: 0.5–0.6 Nm (5 in-lb)

•

Screw size: M3

Terminal

number

Function

35 (-), 36 (+) 24 V DC external supply

Table 3.30 Terminals for 24 V DC external supply

24 V DC external supply can be used as low voltage supply

to the control card and any option cards installed. This

enables full operation of the LCP (including parameter

setting) without connection to the mains. A warning of low

voltage is given when 24 V DC has been connected;

however, there is no tripping.

NOTICE

To ensure correct galvanic isolation (type PELV) on the

control terminals of the frequency converter, use 24 V

DC PELV supply.

3.4.19 Access to Control Terminals

All terminals to the control cables are located beneath the

LCP. They are accessed by opening the door of the IP21/

IP54 unit, or by removing the covers of the IP00 unit.

3.4.20 Wiring to Control Terminals

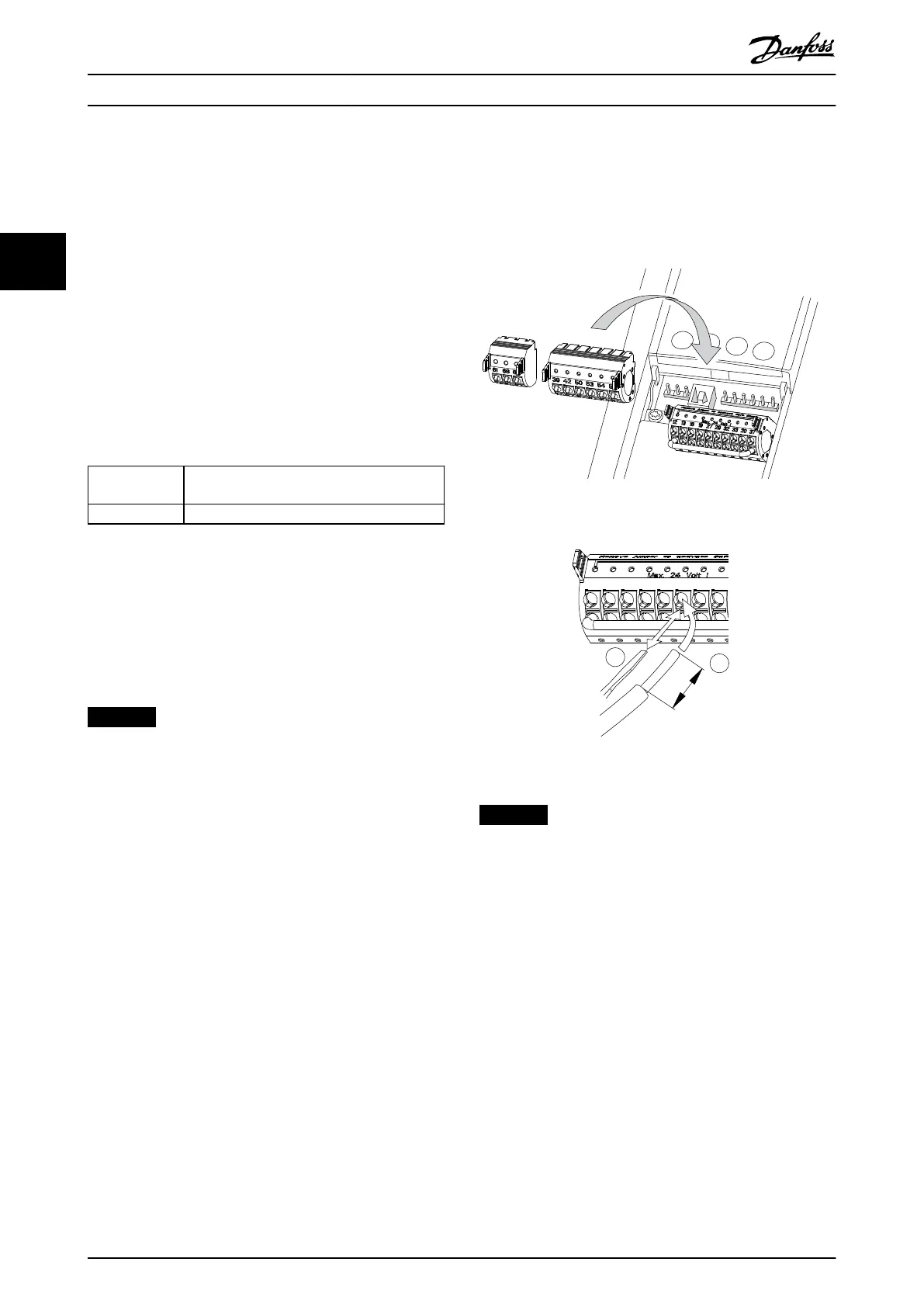

Control terminal connectors can be unplugged from the

frequency converter for ease of installation, as shown in

Illustration 3.48.

Illustration 3.48 Unplugging Control Terminals

130BD546.11

2

1

10 mm

[0.4 inches]

12 13 18 19 27 29 32 33

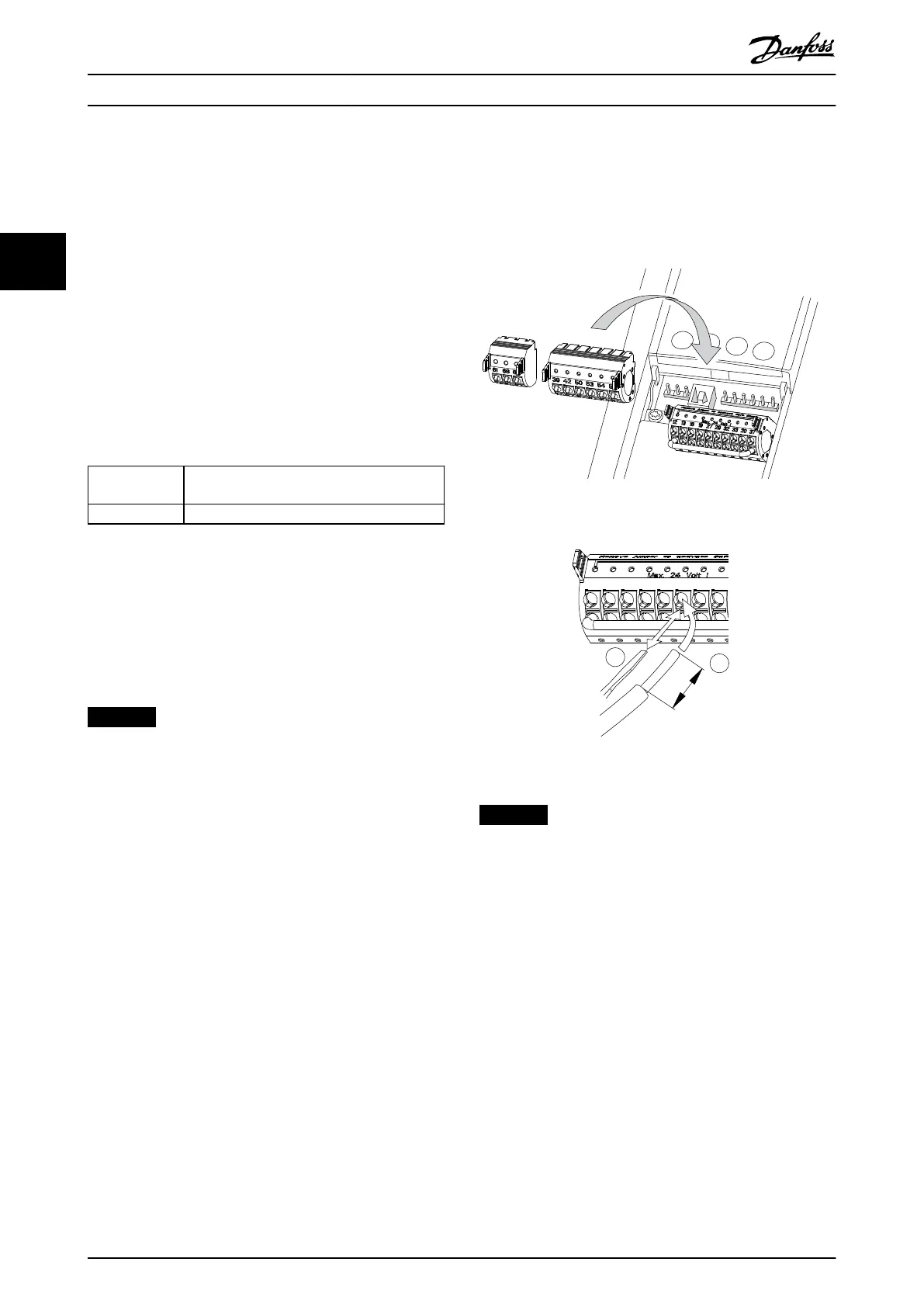

Illustration 3.49 Connecting Control Wires

NOTICE

To minimize interference, keep control wires as short as

possible and separate from high-power cables.

1. Open the contact by inserting a small screwdriver

into the slot above the contact and push the

screwdriver slightly upwards.

2. Insert the bare control wire into the contact.

3. To fasten the control wire into the contact,

remove the screwdriver.

4. Ensure that the contact is rmly established and

not loose. Loose control wiring can be the source

of equipment faults or reduced performance.

See chapter 5.4 Cable Specications for control terminal

wiring sizes and chapter 3.5 Connection Examples for typical

control wiring connections.

How to Install

VLT

®

AutomationDrive FC 302

52 Danfoss A/S © 04/2016 All rights reserved. MG34Q402

33

Loading...

Loading...