Chapter 16 PLC Function ApplicationsC2000

16-137

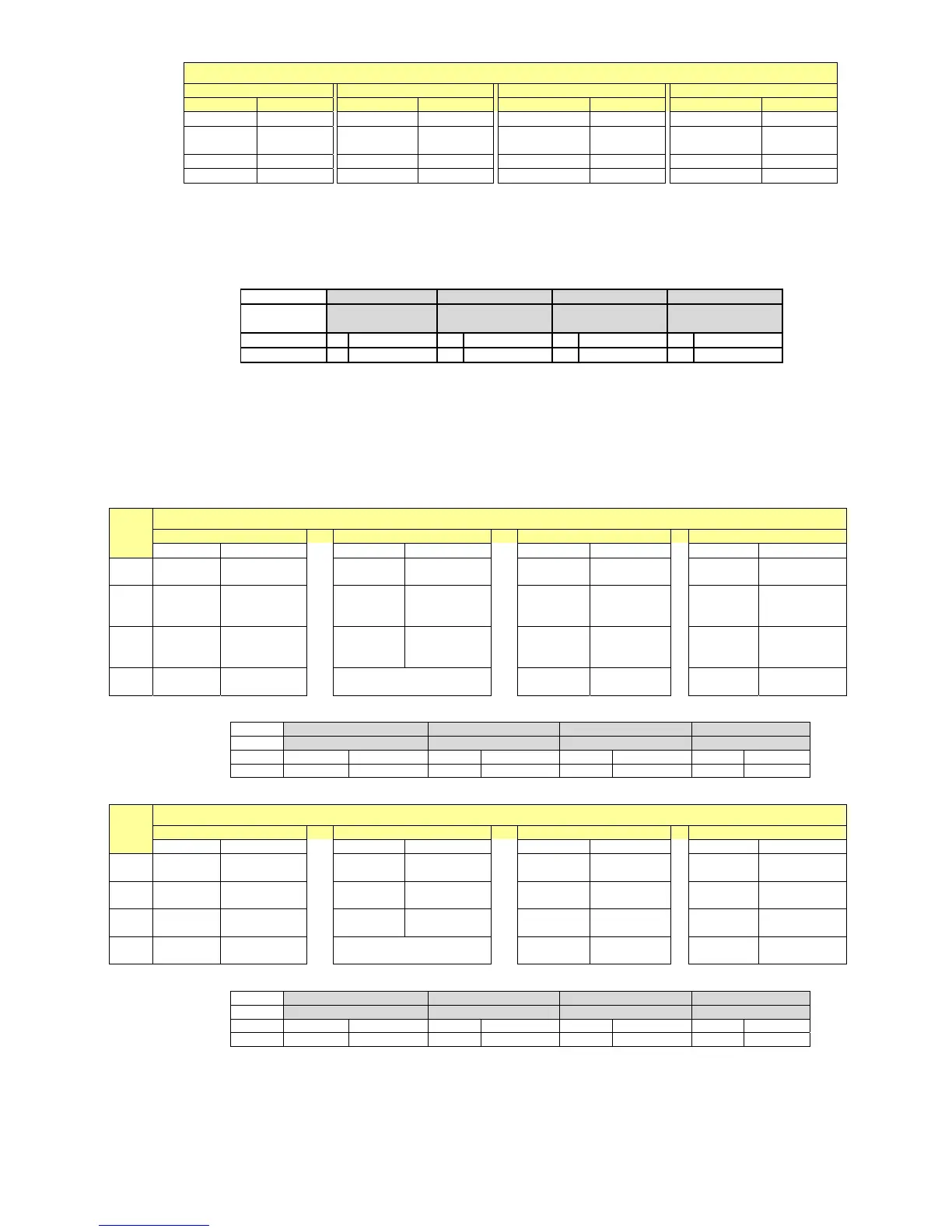

RXPDO

PDO4 (Torque) PDO3 (Position) PDO2 (Remote I/O) PDO1 (Speed)

Description Special D Description Special D Description Special D Description Special D

Mode word D2009+100*n Mode word D2009+100*n Slave device DI D2026+100*n Mode word D2009+100*n

Actual torque D2018+100*n

Actual position

D2022+100*n

D2023+100*n

Slave device AI1 D2028+100*n

Actual frequency D2013+100*n

Actual mode D2011+100*n Actual mode D2011+100*n Slave device AI2 D2029+100*n

Slave device AI3 D2030+100*n

Because usage requires only simple to open the corresponding PDO, where TXPDO employs

D2034+100*n settings and RXPDO employs D2067+100*n settings.

These two special D areas are defined as follows:

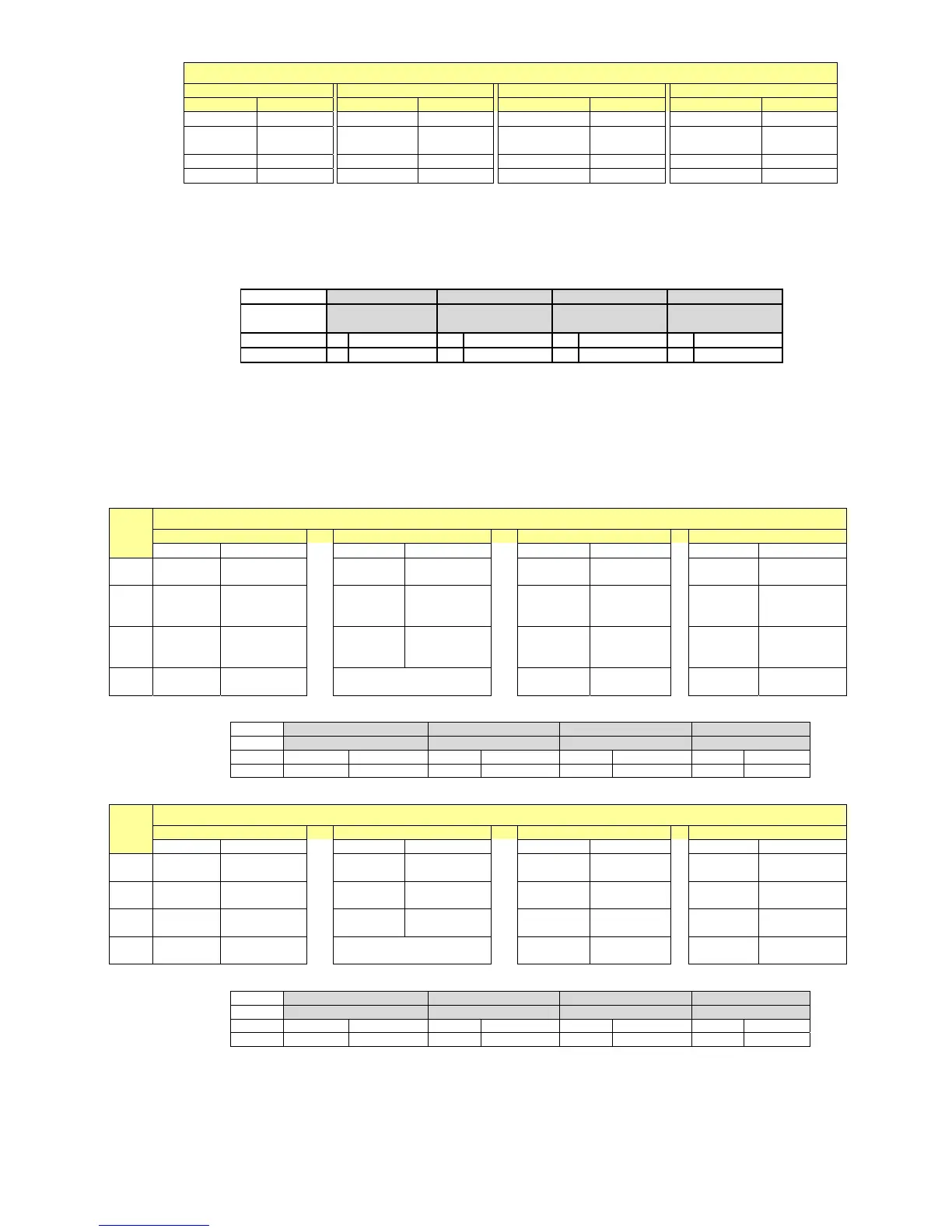

PDO4 PDO3 PDO2 PDO1

Default

definition

Torque Position Remote I/O Speed

bit 15 14–12 11 10–8 7 6–4 3 2–0

Definition En Length En Length En Length En Length

En: indicates whether PDO is used

Length: indicates mapping of several variables

In a simple example, if we want to control a C2000 slave device and make it to operate in speed

mode, we only have to make the following settings:

D2034+100*n =000Ah

Length:

TX PDO

PDO4 PDO3 PDO2 PDO1

Description Special D Description Special D Description Special D Description Special D

1 Controller

Word

D2008+100*n Controller

Word

D2008+100*n Slave

device DO

D2027+100*n Controller

Word

D2008+100*n

2 Target

torque

D2017+100*n Target D2020+100*n

D2021+100*n

Slave

device

AO1

D2031+100*n Target

speed

D2012+100*n

3 Control

method

D2010+100*n Control

method

D2010+100*n Slave

device

AO2

D2032+100*n

4

Slave device

AO3

D2033+100*n

PDO4 PDO3 PDO2 PDO1

Definition Torque Position Remote I/O Speed

bit 15 14–12 11 10–8 7 6–4 3 2–0

Definition 0 0 0 0 0 0 1 2

D2067+100*n =000Ah

Length:

TX PDO

PDO4 PDO3 PDO2 PDO1

Description Special D Description Special D Description Special D Description Special D

1 Controller

Word

D2009+100*n Controller

Word

D2009+100*n Slave

device DI

D2026+100*n Controller

Word

D2009+100*n

2 Actual

torque

D2018+100*n Actual

position

D2022+100*n

D2023+100*n

Slave

device AI1

D2028+100*n Actual

frequency

D2013+100*n

3 Actual

mode

D2011+100*n Actual

mode

D2011+100*n Slave

device AI2

D2029+100*n

4

Slave device

AI3

D2030+100*n

PDO4 PDO3 PDO2 PDO1

Definition Torque Position Remote I/O Speed

bit 15 14–12 11 10–8 7 6–4 3 2–0

Definition 0 0 0 0 0 0 1 2

Switch the PLC to Run after completing settings. Now wait for successful initialization of CANopen

(M1059 = 1 and M1061 = 0), and then initiate CANopen memory mapping (M1034 = 1). The

control word and frequency command will now automatically refresh to the corresponding slave

device (D2008+n*100 and D2012+n*100), and the slave device's status word and currently

Loading...

Loading...