MS300/MH300 PROFINET Communication Card CMM-PN02

CMM-PN02 Operation Manual

4. After you finish setting up the parameter table, recompile the programs and download them to

the PLC program, and then reboot the drive to make CMM-PN02 receive the updated

parameter settings.

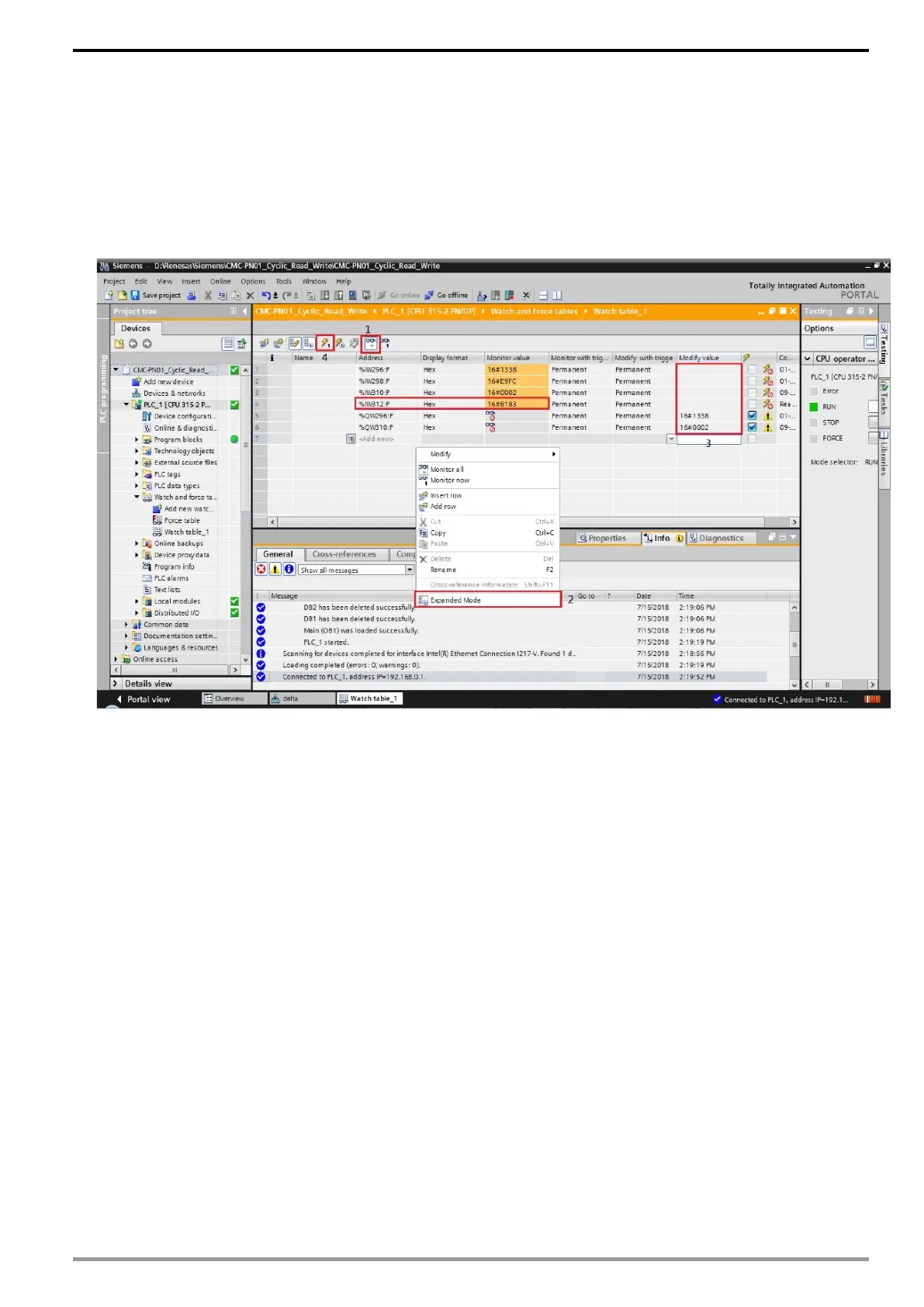

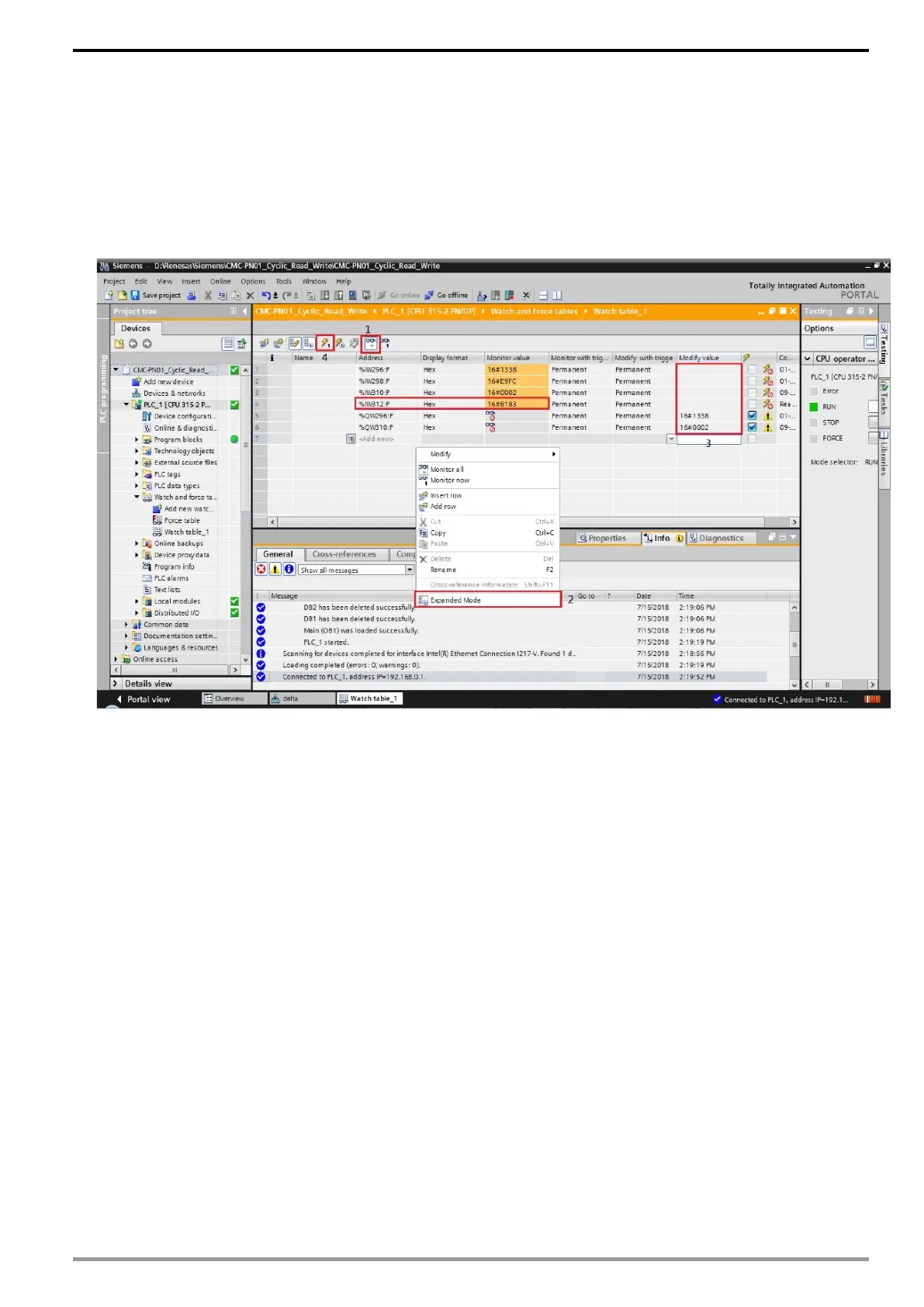

5. When CMM-PN02 is connected to the PLC program successfully, you can test the reading or

writing of the set parameter by using the Watch Table. Refer to the figure below for The Watch

Table.

Follow the four steps below to verify if the settings for the parameter table are applicable and

if reading or writing the drive parameters is successful (Use the keypad to verify.).

NOTE 1: The figure above shows that %IW312 is the status value returned when the parameter table reads or

writes the parameters. Low byte is the status value of reading, whereas high byte is the status value of

writing. Take the figure above as an example, if the status value is 0x8183, the values of 1, 2, and 8 in the

parameter table are successfully read and the values of 1 and 8 are successfully written. Thus, the

success or failure of the parameter reading/writing depends on this status value.

NOTE 2: %IW312 = I/O start address + 56 (the I/O start address in this example is 256).

NOTE 3: Depending on the immediacy of the data, you can choose to write the parameters periodically or

non-periodically

,

Loading...

Loading...