LT-2320

13

CALIBRATION

CALIBRATION

Auto-Calibration

The DV6x CPAP device automatically saves the offset and high

calibration values every time the blower stops for 1 minute. During that

time, the unit adjusts the pressure and ow sensor offsets so that the

proper calibration span is maintained.

Manual Calibration Procedure (Field Service)

The DV63/64 pressure and ow sensors can be calibrated manually

using the following procedure. It is recommended that the PAP be

recalibrated using this procedure whenever the PC board or blower is

replaced or when testing or troubleshooting indicate calibration is

required.

Required Equipment:

• PC with a free serial port

• USB to USB micro-B cable (DV63D-615)

• Terminal Program (Microsoft Windows HyperTerminal or

equivalent)

• Calibrated pressure meter (0 to 30 cmH

2

O range)

• Calibrated mass airow meter (0 to 150 Std. L/min range)

• Ball valve (or equivalent) to control the DV6x device ow

• Particulate Matter (PM) Filter (optional)

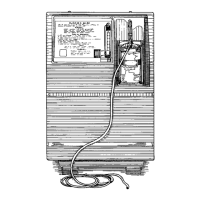

Figure 1 Calibration Setup

PC

USB to

USB Micro-B

Cable

DV65/66 Device

Pressure Meter

Ball

Valve

PM

Filter

Flow

Meter

Procedure:

1. Setup the DV63/64 device as shown in Figure 1 and connect the

DV6x device to the DC power supply. Do not attach the heated

humidier chamber to the DV6x device while performing

calibration. Initially the ball valve should be closed so that no air

can pass through.

2. Use a terminal program (such as Windows HyperTerminal) with

COM settings 9600 baud, no parity, 8 data bits, 1 stop bit, Flow

Control set to none. Open the terminal program and connect to

the DV6x device. When sending terminal commands, the DV6x

device will respond with “WF” if a command was not properly

received, and the command should then be resent.

3. Send the terminal command ‘Mo=3’ to put the device into

calibration mode.

4. Send the terminal command ‘FE=00’ to disable Auto-STOP.

5. In this step the low pressure value and low ow value will be

calibrated. These calibration points are for when the pressure and

ow values equal 0 cmH

2

O and 0 SLPM.

a. Send the terminal command ‘Rs=O’ to ensure the DV6x

device blower is off.

b. Wait forty seconds for the DV6x device internal ltering to

stabilize.

c. Send the terminal command ‘Tc=cpl’ to calibrate the DV6x

device low pressure value.

d. Send the terminal command ‘Tc=c’ to calibrate the DV6x

device low ow value.

6. In this step the high pressure value will be calibrated. This

calibration point is for when the DV6x device blower is on and the

pressure equals 20.0 cmH

2

O.

a. Send the terminal command ‘Tw=18000’ to set the motor

speed to 18,000 RPM. This motor speed value should

achieve a pressure that is close to 20 cmH

2

O.

b. Send the terminal command ‘Rs=R’ to turn the DV6x device

blower on. Check the ball valve to ensure that it is closed,

and that no air is owing through.

c. The external pressure meter should be reading a value that

is equal to 20.0 cmH

2

O. If the pressure does not equal 20.0

cmH

2

O, the terminal commands ‘Tw+’ and Tw-‘ can be used

to increase or decrease the motor speed in small

increments, thus increasing and decreasing the pressure.

Once a pressure that is equal to 20.0 cmH

2

O has been

achieved, wait forty seconds for the DV6x device internal

ltering to stabilize.

d. Send the terminal command ‘Tc=cph’ to calibrate the high

pressure value. NOTE: If the current pressure measurement

is not equal to exactly 20.0 cmH

2

O, the terminal command

‘Tc=cphNN.NN’ can be used to interpolate the pressure

calibration value. For example, the terminal command

‘Tc=cph19.97’ can be used to calibrate the high pressure

value with the interpolated pressure of 19.97 cmH

2

O.

7. In this step the high ow value will be calibrated. This calibration

point is for when the DV6x device blower is on and the ow

equals 110 SLPM.

a. The DV6x device blower should still be turned on at the

motor speed value used for the high pressure calibration in

Step 6, and the ball valve closed.

b. Open the ball valve and adjust the ball valve until the ow

meter measures 110 SLPM.

c. Wait forty seconds for the DV6x device internal ltering to

stabilize.

d. Send the terminal command ‘Tc=cfh’ to calibrate the high

ow value. NOTE: If the current ow measurement is not

equal to exactly 110 SLPM, the terminal command

‘Tc=cfhNNN.N’ can be used to interpolate the ow calibration

value. For example, the terminal command ‘Tc=cfh109.5’ can

be used to calibrate the high ow value with the interpolated

ow of 109.5 SLPM.

8. Testing will be performed to check the ow calibration settings.

Adjust the ball valve to change the ow rate. Send the terminal

command ‘Fl’ and verify that the DV6x device returned ow value

is within ± 4 SLPM of the ow measurement from the ow meter.

Repeat this step at various ow rates.

9. In this step, testing will be performed to check the pressure

calibration settings.

Loading...

Loading...