LT-2320

19

SERVICE

7. Type 'Sn=nnnnnnnnnn' where nnnnnnnnnn is the 10 digit serial

number read in the previous step.

8. Read the hour meter("Uh<cr>)-a new PC Board should have

000000000.0 hours. It is recommended that the original hour

meter value be restored if the original blower is used. Set the

hour meter by typing 'Uh=nnnn<cr>' where nnnn is the hour

meter reading X10 (Ex: 100.5 hours would be set by typing

'Uh=1005<cr>').

9. Read the Compliance Meter ("Up<cr>")-a new PC board should

have 000000000.0. Clear the Compliance Meter if it is not by

typing 'Up=c<cr>'. The CPAP will return 0000000000.0.

NOTE: SmartCode data will also clear at this time.

10. Check the hardware and rmware version information. Read and

record the following:

a. BIOS rev "VB<cr>"

b. Firmware rev "VF<cr>"

Check the present version of rmware to make sure the board is

up to date. Install new rmware if the board has an old revision.

11. Clear the error code by typing 'Ec<cr>' the PAP will return "OK".

12. Clear the fault log by typing 'Uf=c<cr>'the PAP will return "OK".

13. Set all device settings to their default by typing 'TD<cr>. The PAP

should return "OK".

14. Recalibrate the unit using the Manual Calibration Procedure.

15. After the calibration is complete, close Hyper Terminal and set the

clock. This requires the use of the DeVilbiss Remote Control

Program which is included in SmartLink Desktop Software

version 3.0 or higher. If necessary, install the software at this

time.

16. Connect the PAP to a PC Serial Port with cable DV63D-615. In

order to set the clock, open the DeVilbiss SmartLink Desktop

Software and click on the Remote Control Program. When the

program nds the PAP, click on the clock settings tab. Then click

on the clock in the middle of the screen. When you click this, a

message box will let you know that, by clicking this, all data will

be permanently removed and will ask you if you want to proceed.

By clicking "OK" the clock will be set to your computer time, and

all data will be erased.

17. Close the software and disconnect the unit from the PC.

To Remove and Replace LCD Display, Encoder

PC Board, or Manifolds for Pressure and Flow

Transducers

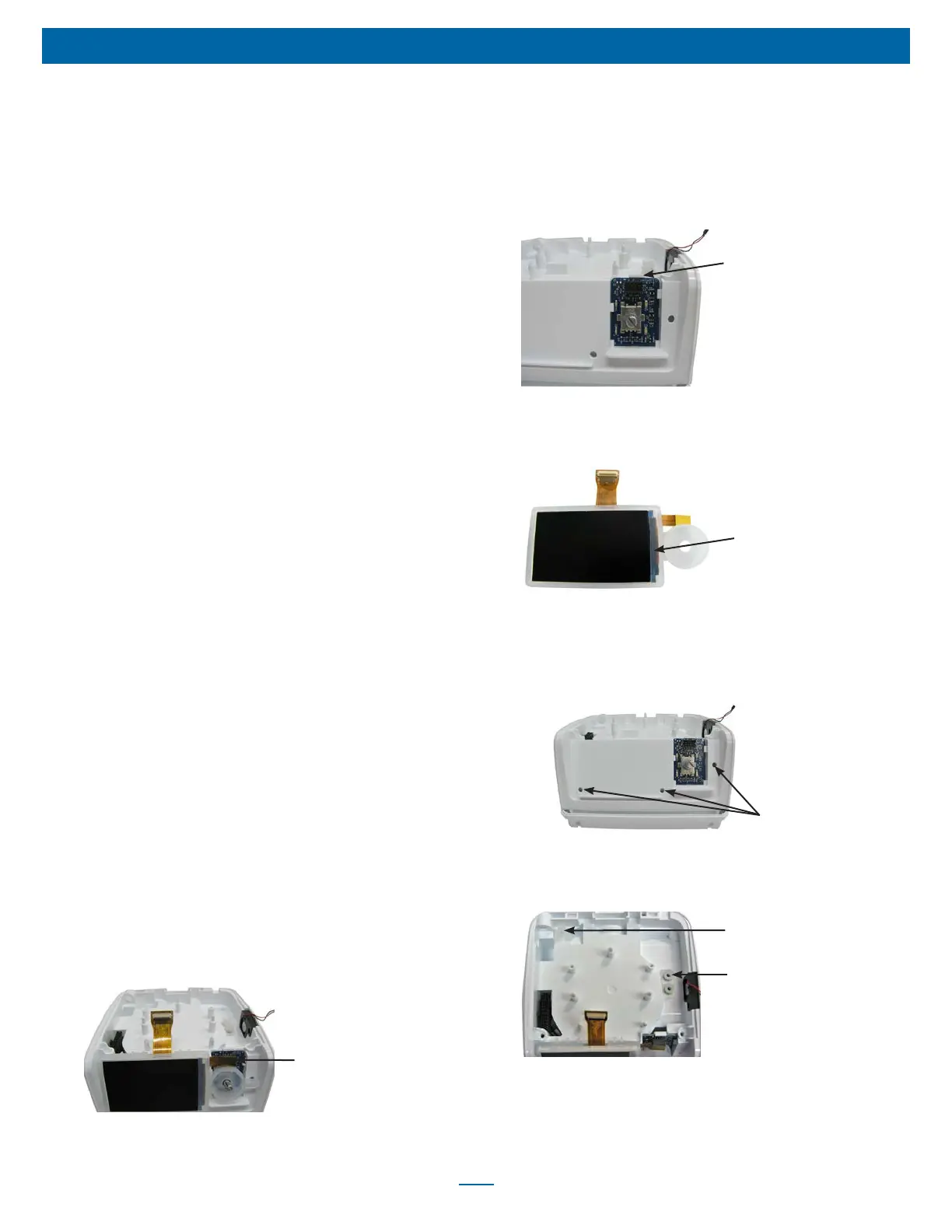

1. Remove PC Board using instructions listed previously and set

aside PC Board with Keypad attached in a safe, clean location.

2. Use a ngernail to gently pry the LCD Display ribbon connector

from Encoder PC board connection.

Disconnect Display Ribbon

Connector from Encoder PC Board

3. Remove the Display and its silicone display mount isolator.

4. If replacing Encoder PC board, release from the chassis by

carefully pushing on the top latch while lifting the rotary knob

stem up until the board is released. Install new Encoder board by

positioning the board so that the Display’s connector is on top,

aligning the board in the chassis guides and pushing into

position. The top latch will click into place.

Push Latch to Remove

Encoder PC Board

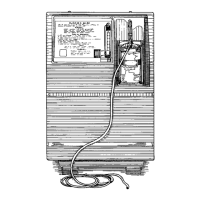

5. If replacing the Display, remove old Display from the silicone

mount isolator and carefully insert new Display ensuring that

neither ribbon connector is bent or damaged in the process.

Silicone Mount Isolator

a. Position the isolator so that the back two plugs align with the

holes in the Display cavity, and the Rotary Knob isolator plug

aligns with the hole to the right of the knob stem. Push the

three plugs into their corresponding holes to attach the

isolator to the main chassis.

Holes for Isolator Plugs X3

b. Attach ribbon connector to the Encoder PC board.

6. If replacing manifolds, pull appropriate silicone manifold from

main chassis.

Pressure Sensor Manifold

Flow Sensor Manifold

a. If replacing the manifold for the pressure sensor, press tall

connector over the larger port in the chassis.

Loading...

Loading...